Imagine giving your ship a fresh coat of protective armor, only to realize months later that it’s peeling away like old wallpaper. That’s what happens when hull cleaning is done improperly—it triggers paint delamination. And once protective coatings fail, your vessel is exposed to the ocean’s unforgiving elements, causing higher fuel costs, structural risks, and compliance headaches.

The phrase paint delamination hull cleaning is becoming a red flag for ship owners, operators, and managers worldwide. It represents the visible proof that maintenance went wrong, revealing weaknesses in coating systems designed to protect one of your biggest assets—your vessel.

In this in-depth guide, we’ll explore how improper hull cleaning leads to paint delamination, what it costs the industry, and how you can prevent this problem with smarter techniques and forward-looking practices.

Why Paint Delamination Matters

Paint on a ship’s hull isn’t decorative—it’s protection. Coatings serve three critical purposes:

- Preventing corrosion by acting as a barrier between steel and seawater.

- Reducing biofouling with anti-fouling paints that deter marine organism growth.

- Improving efficiency by maintaining smooth hull surfaces, lowering resistance, and saving on fuel.

When delamination occurs, this protective layer peels, flakes, or separates from the steel surface. In simpler terms, the armor falls off and leaves your vessel vulnerable.

How Improper Hull Cleaning Causes Delamination

Hull cleaning is necessary for vessel efficiency, but rushing the process—or using aggressive techniques—can undo more harm than fouling itself.

The main culprits are:

- High-pressure water jets damage coatings by stripping paint layers instead of fouling.

- Improper brushes or abrasive tools that scratch and weaken protective coatings.

- Over-cleaning—too frequent or too aggressive cleaning removes anti-fouling layers prematurely.

- Untrained operators are using incorrect techniques without proper inspections.

- Ignoring coating compatibility when shifting between paint systems.

Think of it like taking sandpaper to your car’s paint while washing—it looks clean, but the damage is hiding under the shine. Also, read about underwater hull cleaning in Bangladesh.

Signs of Paint Delamination Exposed During Hull Cleaning

When improper cleaning is carried out, the warning signs are often revealed in patches:

- Blisters or bubbles in coating layers

- Flaking or peeling paint, exposing bare steel

- Discolored patches indicating coating separation

- Rust streaks emerging through failed areas

- Rough, uneven surfaces add drag underwater

If you’ve spotted these issues, it’s more than cosmetic—it’s a maintenance and compliance problem waiting to escalate.

The Hidden Costs of Paint Delamination

Neglecting paint delamination hull cleaning problems can snowball into massive expenses. Here’s what’s at stake:

- Fuel efficiency loss: Rough hull surfaces consume up to 20% more fuel.

- Increased emissions: More fuel burns equal higher CO₂, risking IMO and MARPOL non-compliance.

- Corrosion risk: Exposed steel deteriorates faster, leading to costly dry-docking repairs.

- Insurance implications: Claims may be disputed if poor maintenance is proven.

- Reputation hits: Port authorities may classify neglected vessels as high-risk.

Skipping careful cleaning is like skipping dental checkups—you don’t pay now, but the bill later is painful.

Paint Delamination, Hull Cleaning, and Global Regulations

Paint delamination isn’t merely a maintenance issue; it directly affects compliance.

- IMO Guidelines (imo.org): Promote efficient, sustainable hull management.

- IMCA (imca-int.com): Stress best practices in underwater maintenance to protect integrity.

- MARPOL Convention (Marine Insight): Links fuel consumption, fouling, and emissions control.

- IAPH (iaphworldports.org): Ports increasingly focus on vessel condition for sustainability credentials.

Fouling, fuel, and faulty coatings are more than operational issues—they’re internationally regulated compliance factors.

✅ 4 Things to Check for Safety at Sea pic.twitter.com/dAxhJQ2i6U

— Marine Super Cargo (@Marinsupercargo) September 14, 2025

Best Practices to Prevent Delamination During Hull Cleaning

The good news: delamination is preventable if you apply the right strategies.

- Match cleaning method to coating system: Not all paints tolerate the same cleaning pressures.

- Train your operators: Certified personnel understand the difference between cleaning and damaging.

- Use non-abrasive brushes: Softer tools protect coatings while removing fouling.

- Monitor cleaning frequency: Scheduled cleanings reduce aggressive efforts later.

- Check coating condition first: Inspections help avoid unnecessary damage.

Prevention here isn’t complicated—it’s care, skill, and timing.

Case Study: A Costly Lesson in Delamination

A cargo vessel in the Mediterranean underwent aggressive high-pressure hull cleaning during a routine stop. Within six months, large patches of coating peeled off, doubling fuel consumption and demanding dry-dock recoating. The company spent $600,000 on recoating work—ten times more than routine inspections and gentle cleanings would have cost.

This illustrates how improper methods transform simple maintenance into six-figure headaches.

The Science Behind Coating Failures

Paint delamination results from breaking the bond between the paint layer and the hull. Common scientific triggers include:

- Shear stress caused by strong force (jets or brushes).

- Osmotic blistering—water penetration between the metal and paint layers.

- Thermal expansion—temperature variations leading to cracks.

While corrosion-control coatings are built tough, they aren’t indestructible. Cleaning must respect its physical limits.

Innovative Technologies Preventing Delamination

Future-proof practices are emerging:

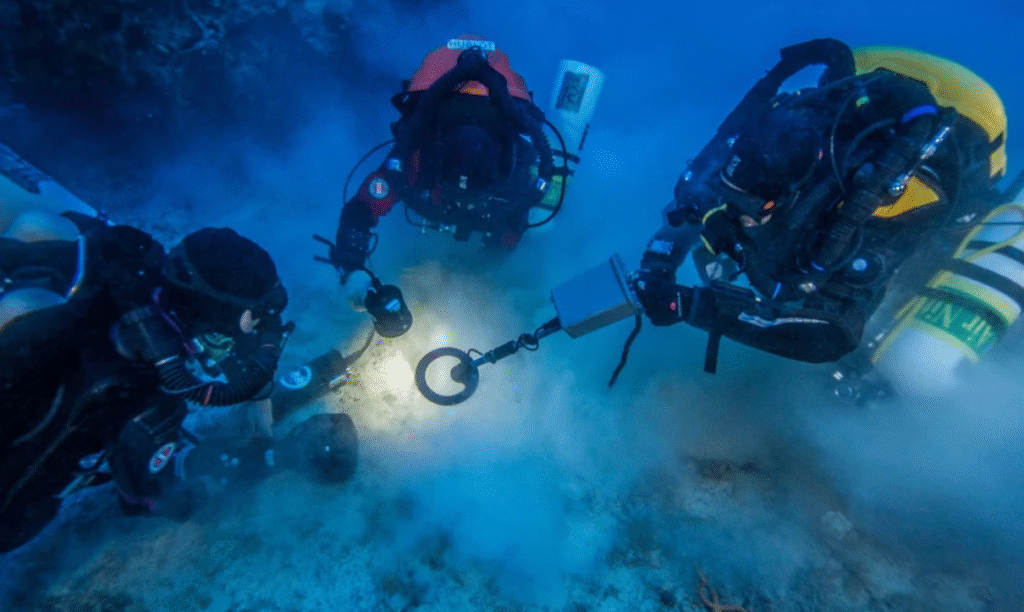

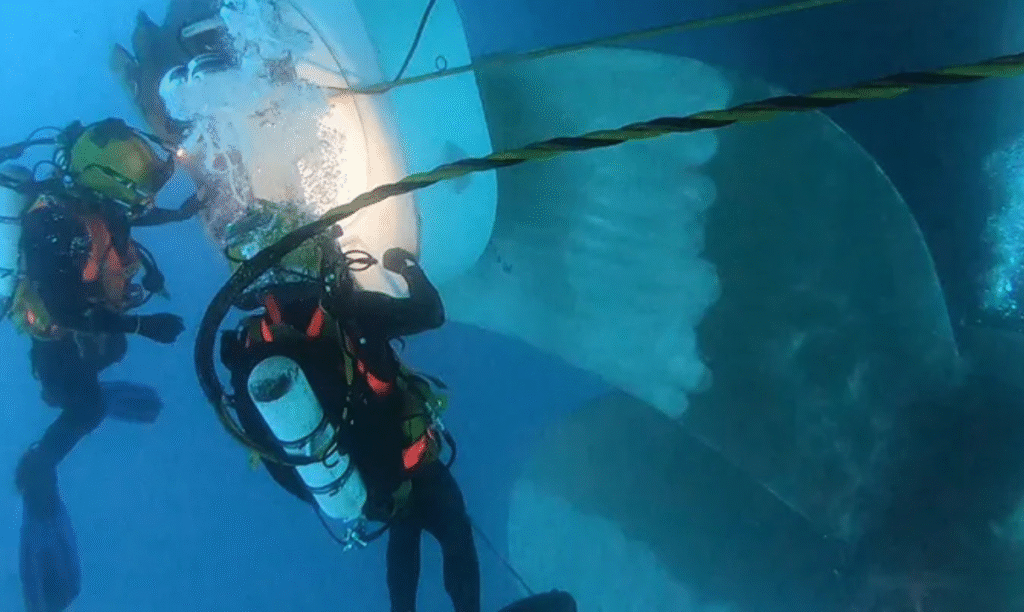

- Robotic hull cleaners: Gentle and consistent, reducing human error.

- AI-driven inspections: Detect weak paint areas before failures occur.

- Eco-friendly brush systems: Designed for less abrasion while protecting coatings.

- Smart coatings: New formulations better resist peeling and delamination.

Together, these innovations turn paint delamination hull cleaning risks into opportunities for smarter, safer maintenance cycles.

Best Practices for Ship Owners and Operators

To cut through the noise, here are the essentials:

- Choose cleaning methods compatible with paint systems.

- Schedule maintenance before fouling layers become aggressive.

- Record coating performance to meet inspection standards.

- Train staff or hire certified service providers.

- Integrate hull cleaning with sustainability goals for cost savings.

Conclusion

Paint delamination is the silent enemy of efficient ship operations. Rooted in improper cleaning, it robs your vessel of protection, efficiency, and compliance. By treating paint delamination hull cleaning as a serious priority, you gain:

- Lower operating costs by preventing fuel loss and structural decay.

- Compliance with IMO, MARPOL, and global inspection requirements.

- Long-term resilience through smarter, gentler maintenance.

Your vessel deserves more than rushed cleaning—it deserves protection that lasts. To safeguard your fleet and ensure sustainable solutions, visit CleanShip.co today.

FAQs:

Q1. What causes paint delamination during hull cleaning?

Aggressive cleaning methods like high-pressure jets and abrasive brushes weaken coatings, eventually causing peeling or blistering.

Q2. Can paint delamination be repaired without dry-docking?

Minor cases can be patched via underwater coating applications, but major peeling often requires dry-docking for full recoating.

Q3. How does paint delamination impact operational efficiency?

It increases hull drag, causing higher fuel burn, greater emissions, and non-compliance risks with IMO fuel efficiency standards.

Q4. Is robotic cleaning safer for ship coatings?

Yes. Robots apply consistent, non-abrasive pressure, reducing the risk of human error that leads to coating failure.

Q5. How often should hull cleaning be performed to avoid delamination?

Cleanings should align with coating life cycles and fouling rates—ideally, quarterly or bi-annual inspections depending on trade patterns.