If ships could talk, the story they’d tell wouldn’t just be about voyages across oceans—it would be about the silent enemies attacking them below the waterline. Among the greatest of these threats are Corrosion Issues that Hull Cleaning often reveals, lurking just out of sight until divers or robots bring them to light.

Corrosion is like rust creeping onto an old bicycle, but under the ocean, it’s far more dangerous and costly. When you’re running a vessel, ignoring the Corrosion Issues that Hull Cleaning uncovers isn’t an option; it’s a direct attack on efficiency, compliance, and safety. That’s why hull cleaning is one of the most critical conversations we need to have in shipping today.

In this article, we’ll unpack the causes, risks, and solutions connected with Corrosion Issues Hull Cleaning highlights. Think of it as your trusted map—guiding you away from costly pitfalls and toward long-term vessel reliability.

Why Hull Cleaning Reveals Corrosion Issues

Hull cleaning doesn’t just strip off marine growth, barnacles, and algae; it acts like a doctor’s check-up for your ship. By removing fouling organisms, we get a clear look at the vessel’s “skin” and often discover hidden problems like Corrosion Issues that Hull Cleaning brings to the surface.

Why does this matter? Because corrosion doesn’t ask permission. It sneaks up slowly but steadily, undermining coatings, weakening structures, and driving up fuel costs. When Corrosion Issues and Hull Cleaning are addressed early, ship owners and operators have a fighting chance to repair them before they snowball into dangerous and expensive failures.

What Is Corrosion in a Marine Environment?

Corrosion occurs when metal reacts with oxygen, water, and salts—perfect conditions found in the ocean. When steel interacts with seawater, electrochemical reactions cause rust, cracks, and structural weakening.

Some common forms of marine corrosion include:

- Uniform corrosion: Spreads evenly across the hull surface.

- Pitting: Small, deep pits that eat away metal faster than surface rust.

- Galvanic corrosion: Happens when dissimilar metals meet in seawater.

- Crevice corrosion: Forms in gaps and joints where oxygen levels change.

Any of these can escalate into dangerous failures if ignored. Hull cleaning turns these invisible threats into visible warning signs.

Corrosion Issues: Hull Cleaning Commonly Exposes

When cleaning teams scrub away fouling, the real battle beneath is revealed. Here’s what surfaces most often:

- Damaged anti-fouling coatings exposing bare steel.

- Localized pitting is hidden under barnacle layers.

- Structural thinning in critical areas like bilges or ballast tanks.

- Signs of galvanic corrosion around propellers, thrusters, or fittings.

- Weld line corrosion occurs where protective coatings wear off first.

These aren’t just cosmetic concerns—they directly impact vessel strength, drag, and fuel efficiency. Also read about underwater hull cleaning in France.

The Real Cost of Ignoring Corrosion

Think about corrosion like cavities in your teeth. Catch them early, and you’ll pay for a routine filling. Ignore them, and they’ll demand painful (and expensive) root canals.

For vessels, unchecked corrosion means:

- Increased fuel consumption: Roughened hull surfaces add drag, raising resistance and burning more fuel.

- Higher emissions: More fuel means more CO₂ output, affecting your compliance with IMO and MARPOL targets.

- Costly downtime: Repairs and dry-docking consume both time and money.

- Weakened safety: Structural integrity is compromised, putting crew and cargo at risk.

Some ship managers underestimate the cumulative effect until audits, port inspections, or accidents force corrections. But by then, costs have already multiplied.

Compliance and Regulations Around Corrosion Control

Corrosion issues hull cleaning uncovers are not just about maintenance—they’re also about compliance obligations.

- IMO: Enforces rules under MARPOL Annex VI, which links fuel efficiency directly to hull conditions.

- IMCA : Issues safety guidelines concerning underwater operations and inspections.

- MARPOL Convention: Imposes international standards on pollution, which are directly affected by increased drag and emissions caused by corrosion.

- IAPH World Ports: Many ports now require documentation of hull condition monitoring for green compliance.

In short, clean hulls and corrosion-free structures aren’t just cost-saving—they’re part of global rules you can’t afford to ignore.

How to Address Corrosion Issues After Hull Cleaning

So, hull cleaning reveals corrosion—what’s next?

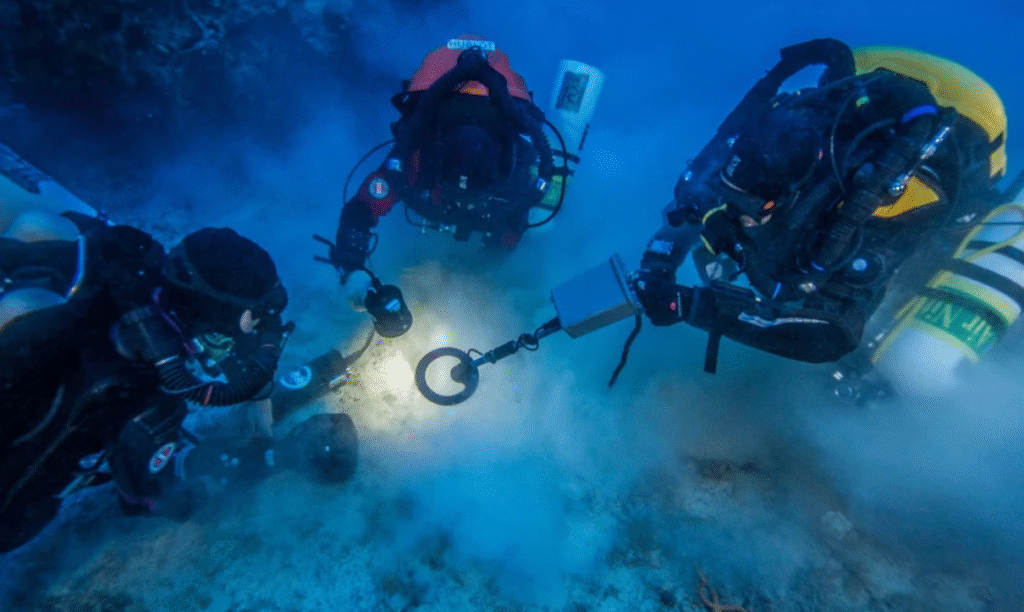

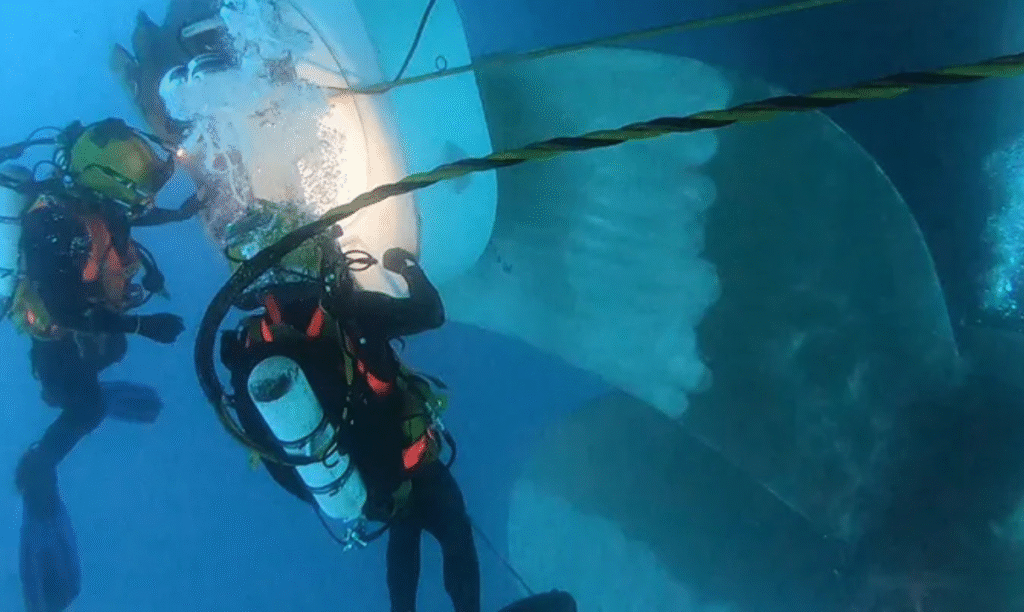

- Inspection and assessment

Document the extent of corrosion with photographs, thickness measurements, and ROV or diver reports. - Surface preparation

Remove rust, debris, and coatings from affected areas to ensure treatment sticks. - Protective coating repairs

Apply new anti-corrosion paints, epoxies, or anti-fouling layers. - Cathodic protection

Use sacrificial anodes or impressed current systems to prevent galvanic corrosion. - Regular monitoring

Integrate corrosion checks into your maintenance cycle alongside hull cleaning.

These steps keep corrosion manageable instead of catastrophic.

✅ 4 Things to Check for Safety at Sea pic.twitter.com/dAxhJQ2i6U

— Marine Super Cargo (@Marinsupercargo) September 14, 2025

Future Trends in Corrosion Detection During Hull Cleaning

Technology is reshaping how we detect and treat corrosion issues, as hull cleaning reveals. Here’s what’s coming:

- AI-driven detection tools: Algorithms that analyze hull images to predict corrosion hotspots.

- ROV-based cleaning and scanning: Robots clean while scanning, reducing diver risk.

- Smart coatings: Materials that “heal” themselves when damaged, slowing down corrosion spread.

- Non-toxic antifouling solutions: Protect the marine environment while lowering biofouling and corrosion risks.

As the shipping industry embraces decarbonization, innovations in hull cleaning and corrosion control will only accelerate.

Case Study: A Tanker’s Costly Lesson

A large crude carrier underwent routine underwater hull cleaning in Singapore. During the job, hidden pitting corrosion beneath barnacle buildup was discovered. Left unattended, the damage could have spread to cargo tank integrity. Immediate repairs cost the company $500,000. Yet, estimates showed delaying the fix could have multiplied losses by ten times if a leak occurred mid-voyage.

This is a sobering reminder: timely detection through hull cleaning saves not only money but also reputations and compliance certifications. Learn more

Best Practices for Ship Owners and Operators

- Schedule frequent cleanings—Don’t wait until growth is visible.

- Use certified service providers—Quality matters when corrosion assessments are made.

- Keep detailed records for audits and inspections.

- Balance cleaning with coating maintenance—Over-cleaning can strip protective paints.

- Stay aligned with sustainability goals—Cleaner hulls reduce emissions and operating costs.

Conclusion

Hull cleaning is more than just aesthetics. It’s where your invisible enemies—pitting, galvanic wear, or coating failures—are first revealed. By treating corrosion issues as an opportunity, smart ship owners gain:

- Lower operating costs from improved efficiency.

- Assurance of compliance with IMO and MARPOL regulations.

- Longer vessel life through preventive action.

The ocean is tough on steel, but with proactive hull cleaning and strong corrosion management, your vessel will stay tougher. For expert, eco-friendly hull maintenance, visit CleanShip.co today.

FAQs:

Q1. Why does corrosion get worse under marine growth?

Marine organisms trap moisture and create micro-environments that encourage electrochemical reactions, accelerating corrosion beneath fouling.

Q2. Is hull cleaning enough to stop corrosion completely?

No. Hull cleaning reveals corrosion, but it must be paired with coating repairs, cathodic protection, and inspections to prevent recurrence.

Q3. How does ignored corrosion affect compliance?

Excessive corrosion increases drag and emissions, risking non-compliance with IMO fuel efficiency regulations and MARPOL pollution standards.

Q4. Can modern coatings really prevent corrosion?

Yes. Advanced epoxies and smart self-healing coatings can delay or reduce corrosion, but regular cleaning is still essential.

Q5. How often should corrosion checks be made?

At least every hull cleaning cycle. High-traffic or harsh-sea vessels may require quarterly or biannual inspections.