When you think of ship maintenance, what comes to mind first? Probably safety checks, engine performance, or even fuel costs. But one often overlooked factor can silently eat into your budget, compliance, and efficiency—paint damage risks during cleaning.

Paint isn’t just about aesthetics. On a ship’s hull, it’s the frontline defense against corrosion, fouling, and drag. However, improper cleaning methods can damage this protective coating, leading to costly repairs, environmental violations, and fuel penalties.

In this article, we’ll explore:

- The biggest paint damage risks during hull cleaning

- Real-world examples of how poor cleaning caused financial losses

- Practical, regulation-aligned solutions to protect coatings

- Future innovations in hull maintenance

By the end, you’ll know how to safeguard your vessel’s hull, reduce costs, and ensure compliance with IMO and MARPOL standards—all while keeping your paint intact.

Why Paint Protection Matters in Hull Cleaning

Imagine the hull as the skin of your ship. Just like our skin protects us from infections, the paint coating protects the vessel from seawater, biofouling, and corrosion. Damage the paint, and suddenly the shield is cracked.

The results?

- Increased drag and fuel consumption

- Accelerated corrosion

- Higher maintenance costs

- Non-compliance with environmental standards

According to Marine Insight and IMO studies, biofouling can increase fuel consumption by up to 40%, but aggressive cleaning that strips the paint may cause even more long-term damage. That’s why striking the right balance is key.

The 7 Major Paint Damage Risks During Cleaning

Excessive Brush Pressure

When divers or robotic cleaners use too much pressure, they often strip away more than just biofouling—they scrape off protective coatings.

- Why it happens: Over-enthusiasm to achieve a “clean look”

- Impact: Paint thins out, exposing the primer or steel

- Real-world case: An IMCA report highlighted a vessel in the Mediterranean where aggressive brushing reduced the antifouling paint life by 50%, forcing an unscheduled dry-dock

⚓ Get Your Ship Cargo Ready with Marine Super Cargo 🚢

— Marine Super Cargo (@Marinsupercargo) September 12, 2025

Your next voyage begins with a vessel that’s clean, compliant, and cargo-ready. At Marine Super Cargo, we deliver top-quality marine services: pic.twitter.com/3627aoKAZo

Using Incompatible Cleaning Tools

Not all brushes and cleaning pads are created equal. Using steel brushes on soft coatings, for instance, is a recipe for disaster.

- Risk: Mechanical abrasion removes paint layers

- Consequence: Shorter coating lifespan and costly recoating

- Best practice: Always match brush hardness with the coating type (IMCA guidelines emphasize this)

Over-Frequent Cleaning

Yes, over-cleaning is a problem too. Think of it like polishing your car daily—the shine fades because the protective wax wears out.

- Why it happens: Misinterpretation of fuel penalty charts

- Risk: Cumulative thinning of coatings

- Tip: Follow manufacturer-recommended intervals rather than cleaning on “gut feeling”

Inadequate Diver Training

Divers are often the unsung heroes of hull cleaning. But without proper training, they can unintentionally cause paint damage risks.

- Example: In Ghana, a study revealed that many divers lacked training on coating compatibility

- Result: Hull coatings got stripped, leading to faster fouling regrowth

- Solution: Certified diver training programs under IMCA standards

Also read about underwater hull cleaning in Ghana.

High-Pressure Water Jetting

High-pressure water jets can be effective but also dangerous if over-applied.

- Risk: Pressure beyond coating tolerance removes paint

- Impact: Patchy protection, exposing steel surfaces

- Regulation: IMO’s guidelines recommend strict PSI monitoring during jetting

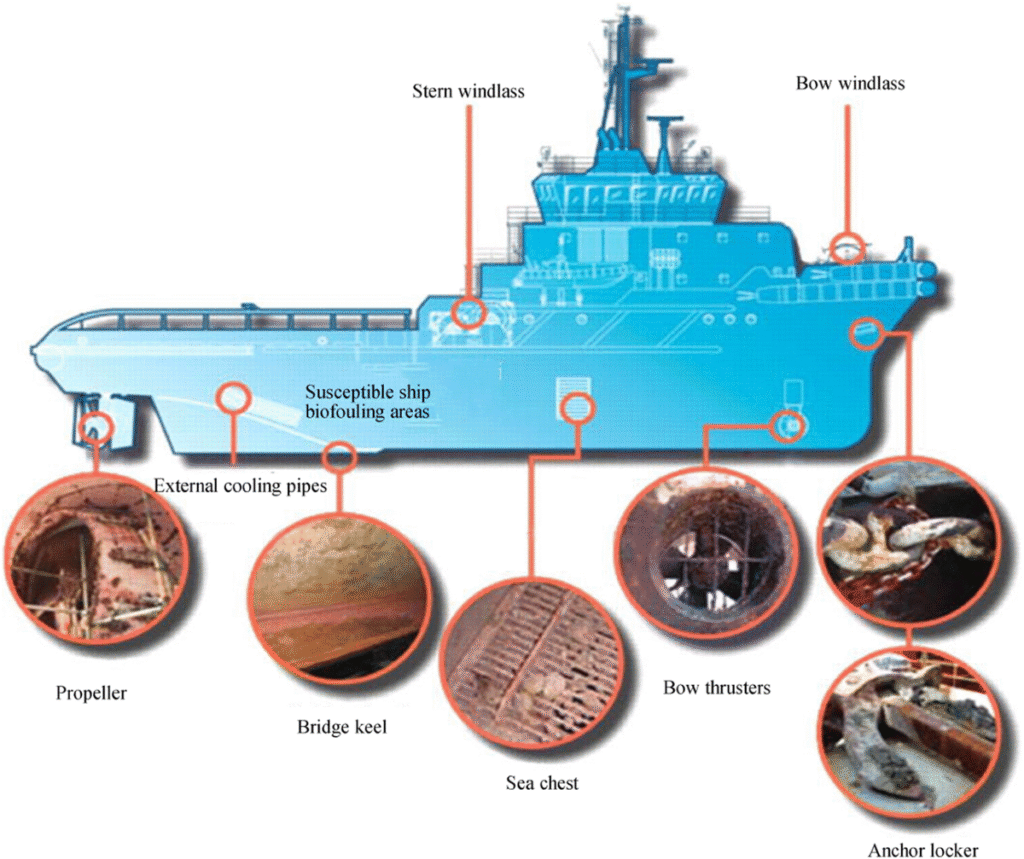

Cleaning Fouled Hulls with Hard Growth

When hard fouling (barnacles, oysters) is already attached, scraping them off can pull paint along with them.

- Why it’s risky: Adhesion strength of barnacles often exceeds the paint bond

- Impact: Localized paint loss, leading to corrosion hotspots

- Prevention: Regular inspections to remove slime before it hardens

Lack of Containment Systems

Modern hull cleaning often involves containment and filtration systems. Without them, paint chips released into the water harm the environment and attract regulatory scrutiny.

- Consequence: Non-compliance with MARPOL Annex V

- Financial penalty: Ports like Singapore and Rotterdam can impose fines

- Best practice: Use cleaning systems with debris capture and waste filtration

The Regulatory Angle: MARPOL, IMO, and Port Rules

Authorities are paying close attention to hull cleaning practices because they intersect with environmental protection and biosecurity.

- MARPOL Annex V prohibits the discharge of paint residues and debris

- IMO Biofouling Guidelines emphasize balancing fouling removal with paint preservation

- IAPH (International Association of Ports and Harbors) has urged ports to only allow certified cleaning contractors

Bottom line: Ignoring paint damage risks isn’t just a technical issue—it can lead to regulatory fines and blacklisting at ports.

Hidden Costs of Paint Damage Risks

Paint damage risks aren’t just a maintenance issue—it’s a financial drain.

- Fuel penalty: Damaged paint increases surface roughness, raising drag by up to 15%, leading to higher fuel bills

- Repainting costs: A single dry-docking and repaint job can cost millions of dollars

- Downtime: Every extra day in dry dock is lost revenue for ship operators

- Insurance risks: Repeated paint failure may trigger non-coverage in marine insurance

Smart Solutions to Prevent Paint Damage Risks

Smart Cleaning Schedules

Use data-driven cleaning intervals, linking cleaning to fuel data and fouling growth.

AI-Powered Robots

Autonomous underwater robots equipped with cameras and sensors deliver precise cleaning without paint over-scrubbing.

Nanotechnology Coatings

Emerging nanotech antifouling surfaces reduce fouling adhesion, meaning gentler cleaning is needed.

Diver Training and Certification

Invest in diver training per IMCA standards to minimize human error.

Containment and Filtration Systems

Capture all fouling debris and paint chips to stay MARPOL-compliant.

The Future of Hull Cleaning: Trends That Protect Paint

- Self-polishing coatings (SPC): These coatings gradually release biocides, reducing fouling and cleaning needs

- Silicone-based fouling release coatings: Smooth surfaces make fouling easier to remove without heavy scrubbing

- Robotic swarm cleaning: Fleets of small robots working in unison for efficient, gentle cleaning

- Data-linked hull monitoring: AI systems predicting optimal cleaning times to reduce unnecessary paint stress

Conclusion

Protecting your hull’s paint is more than just surface-level care—it’s about safeguarding your ship’s efficiency, compliance, and profits. The top 7 paint damage risks we discussed—ranging from over-brushing to poor diver training—are avoidable with smarter strategies.

By adopting data-driven cleaning, certified divers, advanced coatings, and robotic systems, you can dramatically cut costs, extend coating life, and meet IMO/MARPOL compliance.

For expert guidance and eco-friendly hull cleaning solutions, visit CleanShip.co—a trusted name in sustainable marine maintenance.

FAQ:

Q1. What makes coatings vulnerable during cleaning?

Coatings are designed to resist fouling, not excessive abrasion. Rough brushes, scrapers, or over-pressure jets can thin or strip coatings prematurely.

Q2. How do Paint Damage Risks increase fuel costs?

Scratched or eroded coatings create surface roughness, raising drag. IMO estimates fuel penalties rise 2–15% depending on damage severity.

Q3. Are robotic hull cleaners safer for coatings?

Yes, modern ROV cleaners are gentler and include safety controls, but they must still be monitored to avoid repetitive abrasion.

Q4. What’s the most common cause of paint loss during cleaning?

Delayed cleaning. When fouling is allowed to harden, cleaning forces must be harsher, which amplifies paint damage risks.

Q5. How can operators minimize long-term coating loss?

Adopt gentle, frequent cleaning schedules, train operators, align methods to coating types, and adopt eco-certified systems for compliance.