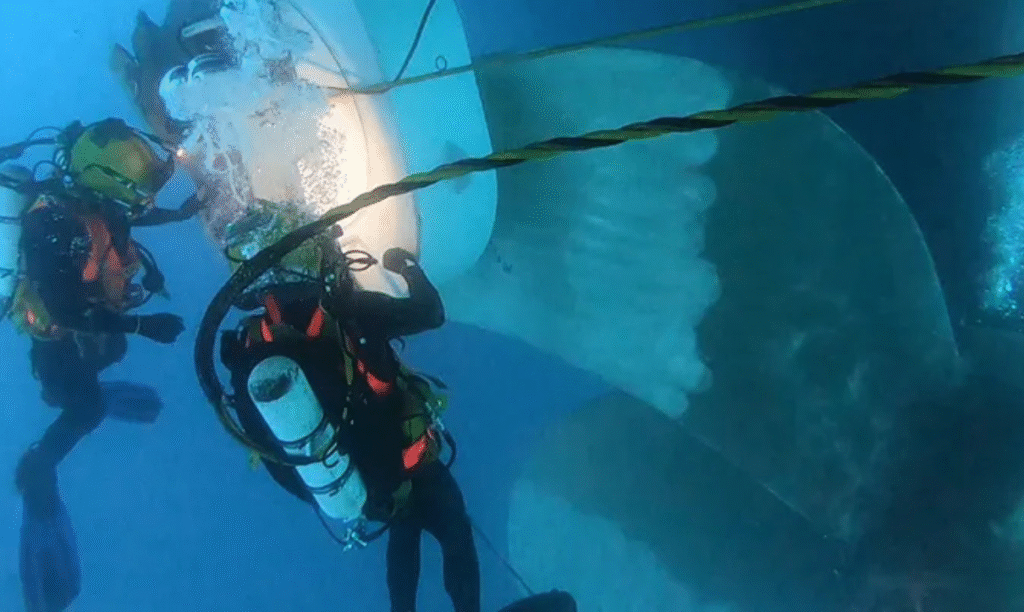

When we think of hull cleaning, we usually picture divers, brushes, and robotic scrubbers tackling stubborn barnacles. But there’s an invisible side effect most people overlook: the waste left behind. Fouling organisms, paint flakes, heavy metals, and toxic residues don’t just vanish—they drift into the water. That’s where Sediment Capture and Containment Systems come in.

Think of these systems as underwater “vacuum cleaners” combined with smart filters. Instead of letting harmful debris spread, they trap and treat it, ensuring that cleaning doesn’t become pollution. In this article, we’ll explore how Sediment Capture and Containment Systems work, why they’re vital, and how they balance compliance, cost savings, and environmental responsibility.

What Are Sediment Capture and Containment Systems?

In simple terms, Sediment Capture and Containment Systems are technologies designed to collect, filter, and properly dispose of fouling residues and paint particles generated during underwater hull cleaning.

They typically include:

- Capture Devices: Suction heads or shrouds attached to cleaning equipment.

- Filtration Units: Multi-stage filters separating sediments, biological matter, and micro-particles.

- Waste Management Solutions: Safe disposal or recycling of collected material.

The result? Cleaner ships, cleaner seas, and a much smaller compliance headache.

Why Do They Matter?

Imagine cleaning your kitchen floor and sweeping dirt under the fridge instead of picking it up. That’s what traditional hull cleaning without capture systems does—it simply shifts the problem into the ocean.

Here’s why Sediment Capture and Containment Systems are game changers:

- Environmental Protection: Preventing toxic paint residues and invasive species from entering marine ecosystems.

- Regulatory Compliance: Meeting IMO biofouling guidelines and MARPOL Convention requirements.

- Cost Efficiency: Avoiding port penalties, reducing downtime, and maintaining coating performance.

- Corporate Responsibility: Demonstrating sustainable operations to clients and regulators.

Technical Aspects of Sediment Capture and Containment Systems

Behind their simple purpose, these systems rely on advanced engineering:

- Hydraulic and Pneumatic Suction: Creating controlled negative pressure to draw in debris.

- Multi-Stage Filtration: Separating biological matter from paint particles and heavy metals.

- Zero-Discharge Design: Ensuring no unfiltered water is released back into the sea.

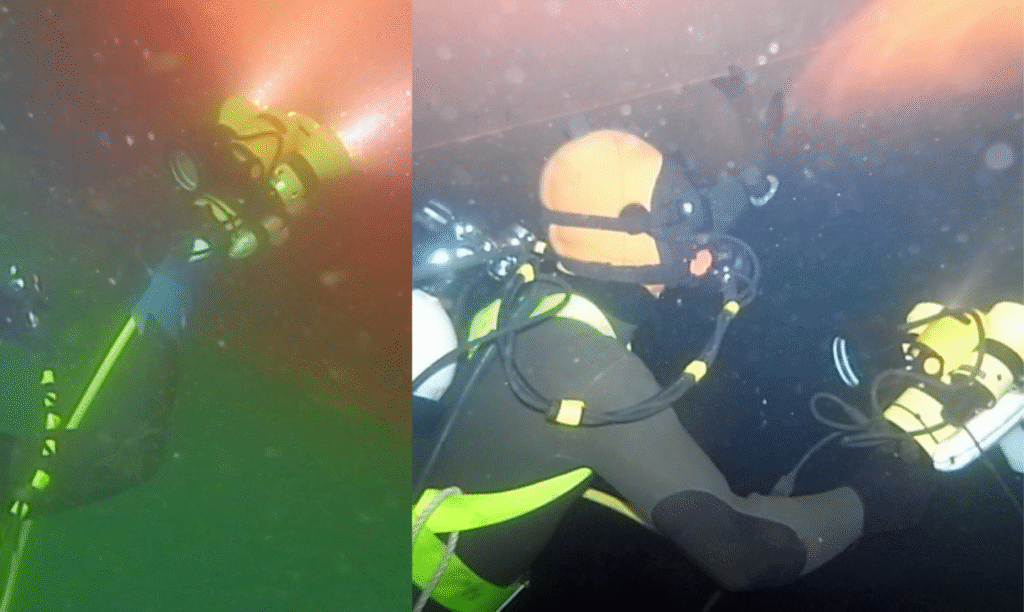

- Mobility: Systems mounted on ROVs (remotely operated vehicles) or diver-assisted units.

Companies like IMCA and IMO emphasize such systems as industry best practices for safe cleaning.

Compliance and Regulations

Global regulators are paying close attention to hull cleaning. The IMO Biofouling Guidelines, MARPOL Convention, and regional port state rules increasingly require sediment containment.

- IMO: Recommends capturing fouling debris to prevent invasive species transfer.

- MARPOL: Prohibits pollution from operational discharges, which includes cleaning waste.

- IAPH Ports: Many ports already ban in-water cleaning without approved containment systems.

Failing to use Sediment Capture and Containment Systems can mean hefty fines, vessel detention, or even outright bans from certain waters. Also read about underwater hull cleaning in Ghana.

Environmental Impact

Hull fouling waste isn’t just unsightly—it’s dangerous:

- Toxic Metals: Old antifouling paints release copper and zinc.

- Microplastics: Paint particles act like sponges, absorbing harmful chemicals.

- Invasive Species: Organisms survive cleaning and spread to new ecosystems.

By containing sediments, these systems act like a “firewall” between ships and the sea, stopping ecological damage before it starts.

Cost-Saving Benefits

Yes, installing or hiring Sediment Capture and Containment Systems has upfront costs. But consider the savings:

- Fuel Savings: Cleaner hulls mean smoother voyages, cutting up to 15% in fuel use.

- Avoided Penalties: Non-compliance fines can reach hundreds of thousands of dollars.

- Coating Preservation: Prevents abrasive damage to expensive antifouling paints.

- Insurance Benefits: Demonstrating compliance can lower operational risk premiums.

As the saying goes, “an ounce of prevention is worth a pound of cure.”

✅ 4 Things to Check for Safety at Sea pic.twitter.com/dAxhJQ2i6U

— Marine Super Cargo (@Marinsupercargo) September 14, 2025

Best Practices for Using Sediment Capture and Containment Systems

- Plan Ahead: Schedule cleaning in ports where containment technology is available.

- Inspect Equipment: Ensure suction and filters are functioning before diving in.

- Train Crew: Knowledgeable operators ensure efficient, safe sediment capture.

- Record Waste Disposal: Keep logs for port inspections and audits.

- Partner with Certified Providers: Companies like CleanShip.co specialize in compliant solutions.

Future of Sediment Capture Technology

Innovation is accelerating. Here’s what the next decade may bring:

- Autonomous Capture Units: Self-operating robots collecting and filtering waste.

- Onboard Treatment Plants: Ships equipped to process sediments without port dependency.

- AI Monitoring: Predicting fouling levels and optimizing cleaning schedules.

- Eco-Friendly Coatings: Reducing debris at the source, making capture systems more efficient.

The future is not just clean—it’s smart.

Case Study: Containment in Action

A bulk carrier operating in Southeast Asia faced repeated bans on in-water cleaning. By switching to a contractor using Sediment Capture and Containment Systems, the vessel achieved:

- 100% compliance with port rules

- 12% fuel savings in one year

- Zero invasive species transfers recorded in follow-up inspections

This shows how compliance, cost savings, and environmental protection align when best practices are applied.

Conclusion

Hull cleaning isn’t just about removing fouling—it’s about doing it responsibly. Sediment Capture and Containment Systems are the backbone of eco-compliant cleaning, ensuring waste is managed instead of dumped.

Key Takeaways:

- These systems protect marine ecosystems from toxins and invasive species.

- They safeguard compliance with IMO, MARPOL, and port regulations.

- They save money through reduced fuel costs and avoided penalties.

For guaranteed compliance and eco-friendly results, partner with CleanShip.co—the trusted leader in sustainable hull cleaning.

FAQs:

Q1. What are Sediment Capture and Containment Systems?

They are technologies that trap and filter debris during underwater hull cleaning, preventing toxic waste and invasive species from polluting the ocean.

Q2. Are these systems mandatory worldwide?

Not everywhere, but many ports and regions already require them. Compliance is growing under the IMO and MARPOL frameworks.

Q3. Do containment systems slow down cleaning?

No. With modern equipment, cleaning is efficient, and debris capture happens simultaneously, ensuring both speed and compliance.

Q4. How are sediments disposed of?

Captured waste is filtered, stored, and delivered to certified onshore disposal or recycling facilities, ensuring safe handling.

Q5. What role does CleanShip play?

CleanShip.co provides certified underwater cleaning services with containment systems, helping ships stay efficient, compliant, and environmentally safe.