Specialized Molasses Tank Cleaning Solutions in Suez

Molasses tank cleaning Suez presents unique challenges requiring specialized expertise and advanced techniques unavailable through standard maritime cleaning services. The viscous, adhesive nature of molasses creates stubborn residues that coat tank surfaces from bow to stern, demanding intensive cleaning protocols. Marine Super Cargo delivers comprehensive solutions at Suez Port, addressing the complexities of sticky cargo removal with proven methodologies.

Molasses tank cleaning Suez operations align with MARPOL Annex II requirements governing noxious liquid substances. While molasses poses minimal environmental hazards compared to petroleum products, proper waste handling remains mandatory. The International Maritime Organization establishes guidelines ensuring molasses tank cleaning Suez residues receive appropriate treatment, protecting marine ecosystems throughout sensitive canal zone waters.

Advanced Techniques for molasses tank cleaning Suez Success

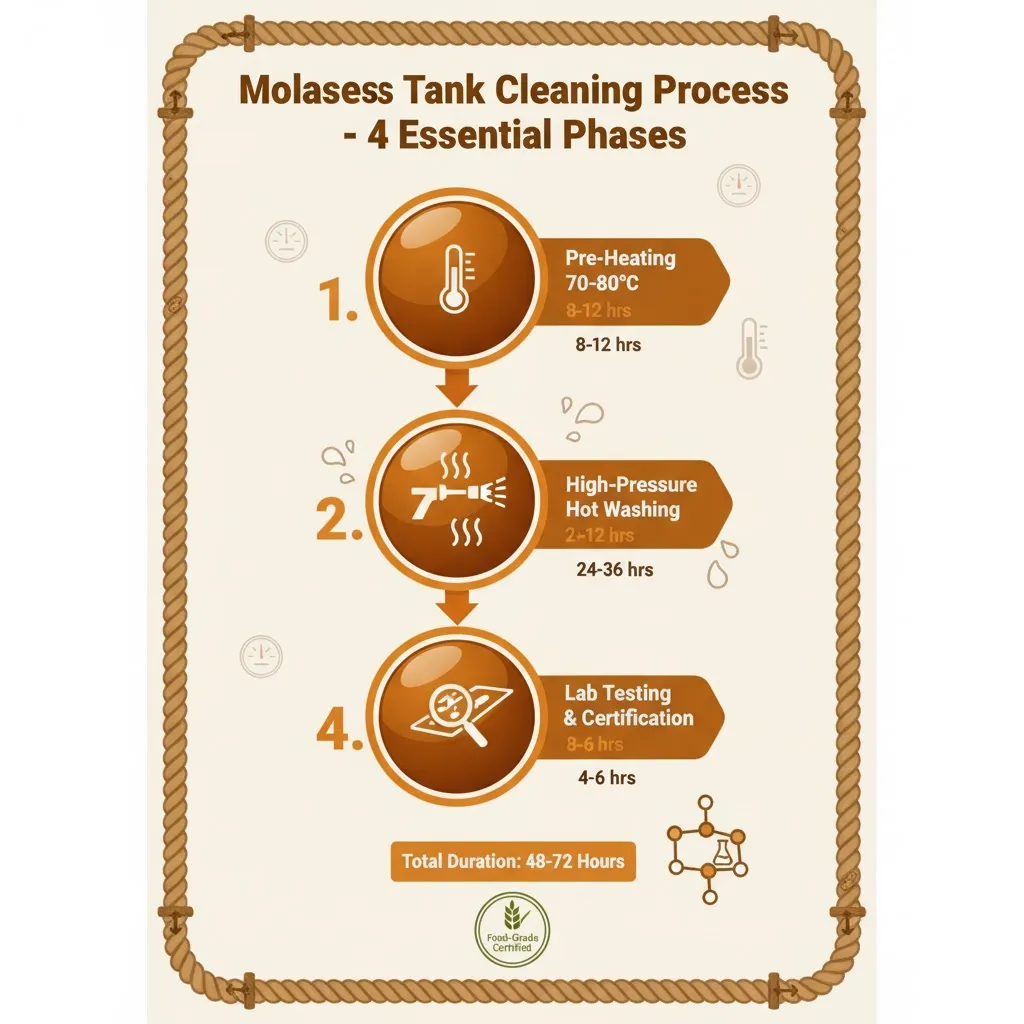

Molasses tank cleaning Suez begins with extensive pre-heating procedures. Steam injection systems raise tank temperatures to 70-80°C, liquefying hardened molasses residues coating surfaces throughout cargo holds. This thermal preparation proves essential for molasses tank cleaning Suez, as cold-water methods prove completely ineffective against crystallized sugar deposits. Heating continues for 8-12 hours, ensuring heat penetrates throughout tank structures from forward compartments to aft sections.

High-temperature, high-pressure washing follows thermal preparation during operations. Specialized nozzles deliver water heated to 80-90°C at pressures exceeding 10 bar, dislodging softened molasses residues. Multiple wash cycles ensure complete coverage, addressing areas behind structural members and within tank corners where residues accumulate. As discussed in our vegetable oil tank cleaning article, maintaining elevated temperatures throughout washing prevents residue re-hardening on cooling surfaces.

Quality Verification and Inspection Procedures

Molasses tank cleaning Suez completion requires comprehensive verification procedures. Visual inspection confirms no visible residue remains on tank surfaces, with particular attention to areas prone to deposit accumulation. The white glove test—running clean fabric across surfaces—detects sugar residues invisible to naked eye inspection. Only after passing these stringent tests does molasses tank cleaning Suez receive completion certification.

Laboratory analysis provides objective evidence of molasses tank cleaning Suez effectiveness. Samples from tank surfaces and final rinse water undergo testing measuring sugar content and detecting residual contamination. Marine Super Cargo maintains onsite testing facilities delivering rapid analytical results, allowing immediate remediation if initial attempts don’t achieve required standards.

Environmental Compliance and Waste Management

molasses tank cleaning Suez generates substantial quantities of sugar-contaminated wastewater requiring proper treatment. Collection systems capture all washing effluent, preventing discharge into Suez Port waters. Treatment facilities process this waste according to IMO environmental standards, separating organic matter before disposal. Marine Super Cargo operates advanced wastewater treatment systems ensuring operations maintain environmental compliance.

The MARPOL framework governs discharge standards for residues. While molasses represents a relatively benign substance environmentally, concentrated sugar solutions deplete oxygen in receiving waters, harming aquatic life. Professional cleaning services prevent environmental damage through proper waste containment and treatment protocols.

Documentation of molasses tank cleaning Suez waste disposal satisfies regulatory requirements. Waste transfer receipts, treatment certificates, and disposal manifests provide verifiable evidence of environmental compliance. Port state control authorities review these documents during inspections, ensuring vessels maintain proper waste management practices throughout cleaning operations.

Economic Considerations and Service Value

molasses tank cleaning Suez represents significant investment for vessel operators, but professional services prevent costly complications. Inadequate cleaning leads to cargo contamination, rejection, and substantial financial losses far exceeding service costs. The economic value of thorough molasses tank cleaning Suez becomes evident when vessels load high-value food cargoes without contamination concerns.

Time efficiency distinguishes professional molasses tank cleaning Suez from inadequate services. Marine Super Cargo optimizes heating, washing, and verification procedures, minimizing vessel port time while achieving superior results. This efficiency reduces opportunity costs associated with extended cleaning operations, allowing vessels to maintain tight operational schedules through the Suez Canal.

FAQs About molasses tank cleaning Suez

Q1: Why is molasses tank cleaning more difficult than other cargo types?

Molasses’ high sugar content and viscosity create extremely adhesive residues that harden when exposed to air, requiring extensive heating and specialized cleaning techniques for complete removal.

Q2: How long does molasses tank cleaning take at Suez Port?

Complete cleaning typically requires 48-72 hours including pre-heating (8-12 hours), washing cycles (24-36 hours), inspection, and verification procedures.

Q3: Can tanks be cleaned between molasses and other food cargoes?

Yes, professional molasses tank cleaning Suez achieves food-grade cleanliness standards, allowing safe transitions to edible oils, wines, juices, or other food products without contamination risks.

Q4: What temperature is necessary for effective molasses tank cleaning ?

Tank heating to 70-80°C and wash water temperatures of 80-90°C are essential for liquefying hardened molasses and preventing re-crystallization during cleaning operations.

Q5: What certifications does Marine Super Cargo provide after molasses tank cleaning ?

Complete tank cleanliness certificates, laboratory analysis confirming food-grade standards, waste disposal documentation, and MARPOL Annex II compliance records.