Imagine trying to wash a delicate silk shirt with a heavy-duty scrub brush. The shirt may look cleaner for a moment, but the fibers will weaken, and eventually, it will tear. The same idea applies to ships. Every vessel is coated with specialized paints designed to resist fouling, reduce drag, and protect against corrosion. But if the wrong cleaning methods are used, that protective paint layer can be damaged—leading to costly consequences.

As ship operators, owners, and managers, we know the sea is both our pathway and our challenge. Maintaining a clean hull is crucial for efficiency, compliance, and sustainability. But here’s the catch: cleaning methods and paint types must work in harmony. If not, the very act of cleaning can undo years of careful protection.

In this guide, we’ll explore why compatibility matters, the risks of mismatched approaches, the science behind common cleaning methods, global compliance frameworks, and future innovations. Let’s dive beneath the surface.

Why Cleaning Methods and Paint Compatibility Matter

Hull coatings are not just “paint.” They are engineered systems designed to repel organisms and withstand saltwater’s harsh effects. Cleaning is meant to restore efficiency—but when mismatched, it can:

- Strip away expensive coatings prematurely.

- Release harmful biocides and residues into the sea.

- Increase fuel costs due to roughened surfaces.

- Violate environmental regulations such as MARPOL.

The right cleaning methods are like using the right soap for your skin—too harsh, and you irritate it; too mild, and dirt remains. The balance determines both performance and longevity.

Understanding Paint Types

Before pairing paints with cleaning, let’s review the main categories.

1. Antifouling Paints

- Contain biocides (like copper) that leach slowly to deter fouling.

- Effective but vulnerable to aggressive scrubbing, which can release chemicals.

2. Fouling-Release Coatings

- Often silicone-based, creating slick surfaces where organisms struggle to attach.

- Require gentle cleaning to maintain smoothness.

3. Self-Polishing Copolymers (SPCs)

- Wear down gradually, exposing fresh biocides.

- Compatible with controlled brushing but damaged by high-pressure methods.

4. Epoxy & Protective Coatings

- Provide corrosion resistance under antifouling layers.

- If exposed, they should never be aggressively cleaned.

Each type has strengths, but their survival depends on compatible cleaning methods.

✅ 4 Things to Check for Safety at Sea pic.twitter.com/dAxhJQ2i6U

— Marine Super Cargo (@Marinsupercargo) September 14, 2025

Common Cleaning Methods Explained

Here’s a breakdown of widely used hull cleaning techniques, with their pros, cons, and paint compatibility.

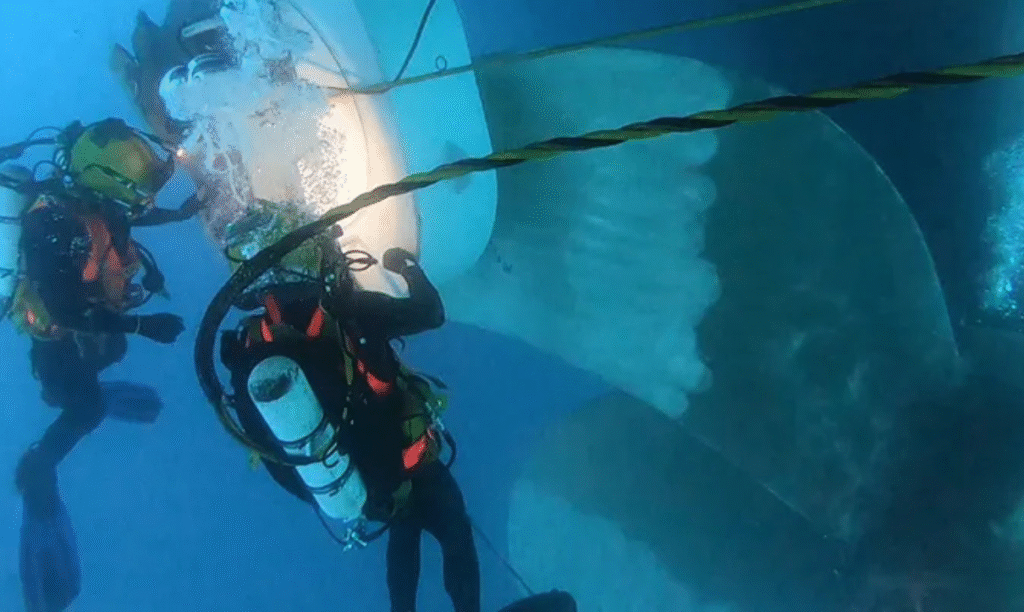

1. Diver-Assisted Brushing

Divers use hand-held brushes or hydraulic tools.

- Pros: Effective, flexible, low-tech.

- Cons: Risk of stripping antifouling paints.

- Best for: Light fouling on durable coatings.

2. High-Pressure Water Jetting

Pressurized jets blast off fouling.

- Pros: Fast, effective on stubborn growth.

- Cons: Can erode paint layers, releasing chemical residues.

- Best for: Limited use on robust SPC coatings.

3. Robotic Hull Cleaning

Autonomous or remote-operated robots with brushes or suction.

- Pros: Precise, consistent, often with residue collection.

- Cons: High upfront cost.

- Best for: Fouling-release coatings, eco-conscious operators.

4. Cavitation Bubble Jets

Microbubbles collapse with force, loosening fouling.

- Pros: Gentle, less coating damage.

- Cons: Newer, not yet widely adopted.

- Best for: Modern paints like silicone-based coatings.

5. Containment & Filtration Systems

Cleaning units capture and filter waste.

- Pros: Environmental compliance, residue-free.

- Cons: Requires advanced infrastructure.

- Best for: Sensitive ports with strict rules.

Each of these cleaning methods interacts differently with paints. Selecting the wrong one is like using sandpaper on glass—it works, but at a heavy cost.

Also read about underwater ship hull cleaning in Ghana.

Risks of Mismatched Cleaning

When cleaning methods clash with coatings, the consequences ripple outward:

- Paint Damage: Aggressive cleaning strips away protective layers, exposing bare hulls.

- Environmental Harm: Damaged antifouling paints release copper and biocides, polluting marine ecosystems.

- Increased Drag: A rough surface, even clean, can increase drag more than light fouling.

- Regulatory Breaches: Ports and frameworks like IMO now demand eco-friendly methods.

Imagine polishing a car with steel wool. You may remove dirt, but you’ll also destroy the paint job. That’s what happens when cleaning doesn’t match paint type.

Compliance and Global Standards

The shipping industry doesn’t operate in isolation. International rules guide safe practices.

- IMO Guidelines: IMO emphasizes environmentally sound hull cleaning.

- MARPOL Convention: Outlines strict measures against chemical discharge.

- IMCA Standards: IMCA provides best practices for marine contractors.

- IAPH Initiatives: IAPH works toward harmonized port cleaning standards.

- Local Port Restrictions: Many ports ban in-water cleaning unless waste is contained.

Compliance isn’t just paperwork—it’s about credibility, avoiding fines, and maintaining global access.

Cost Implications

Cleaning is an investment, but mismatches turn it into a liability.

- Fuel Costs: A smooth, clean hull can cut fuel use by 10–20%. But damaged coatings may reverse these gains.

- Maintenance Costs: Early repainting means extra dry-docking.

- Fines: Violations can cost up to $200,000 in some regions.

- Case Example: A tanker faced penalties in Singapore after an uncontrolled residue release. Switching to robotic cleaning with containment saved fuel and avoided future fines.

Choosing compatible cleaning methods is both eco-smart and wallet-smart.

Future Trends in Cleaning and Paint Compatibility

The industry is evolving fast, with promising solutions on the horizon.

- AI-Powered Monitoring: Sensors predict fouling buildup and recommend the least-damaging cleaning schedules.

- Eco-Friendly Coatings: Biocide-free paints designed to repel organisms naturally.

- Robotics + Filtration: Standardized robots with built-in waste capture becoming industry norm.

- Global Certifications: Expect “green cleaning” labels for compliant ships.

- Nanotechnology: Advanced surfaces that self-clean, reducing the need for frequent intervention.

The future is clear: sustainable shipping will hinge on aligning cleaning methods with coating technologies.

Conclusion

Hull maintenance isn’t just about keeping ships shiny. It’s about pairing the right cleaning methods with the right paint systems. Get it wrong, and you risk environmental harm, regulatory fines, and rising costs. Get it right, and you gain efficiency, compliance, and long-term savings.

Three key takeaways:

- Paint and cleaning compatibility is essential for sustainability.

- Compliance saves both money and reputation.

- Innovative providers like CleanShip.co are leading with eco-friendly, compatible solutions.

By choosing wisely, you’re not just cleaning a hull—you’re protecting oceans, profits, and the future of shipping.

FAQs:

Q1. What are the most common cleaning methods for ship hulls?

They include diver brushing, high-pressure jetting, robotic cleaning, cavitation bubbles, and containment systems—each suited to different paint types.

Q2. Why does compatibility with paint types matter?

Because the wrong cleaning method can strip coatings, increase drag, release toxins, and raise costs—undoing the benefits of hull maintenance.

Q3. Which paints are most sensitive to aggressive cleaning?

Fouling-release and silicone-based coatings require gentle methods, while self-polishing paints can handle more controlled brushing.

Q4. How do regulations impact cleaning methods?

International frameworks like IMO and MARPOL, along with local port rules, restrict methods that release residues into the sea.

Q5. What’s the future of hull cleaning?

Expect smarter robots, eco-friendly coatings, AI monitoring, and global standards that align cleaning methods with sustainable shipping goals.