Imagine sending divers deep under a vessel to inspect every nook and cranny. Risky, time-consuming, and expensive, right? Now picture a drone—like a flying and swimming detective—that captures every detail of your ship’s hull with precision and without putting a single human life at risk. That’s the difference Drone Hull Inspections make.

In this article, we’ll explore how drones are redefining hull inspection before cleaning, why ship operators can’t afford to ignore this technology, and how embracing it not only optimizes costs but also aligns with international safety and compliance standards.

Why Hull Inspections Matter Before Cleaning

Before you even begin hull cleaning, inspections are critical. Here’s why:

- Fouling assessment: To check the level of algae, barnacles, or slime growth.

- Planning efficiency: Helps decide whether light cleaning, heavy scrubbing, or coating touch-ups are needed.

- Cost control: Prevents unnecessary cleaning in lightly fouled areas.

- Compliance assurance: Confirms the vessel won’t violate IMO’s biofouling regulations.

Skipping inspections is like mowing your lawn in the dark—you might cut what you can feel, but you’ll miss patches and waste time.

Traditional Hull Inspections: The Old Way

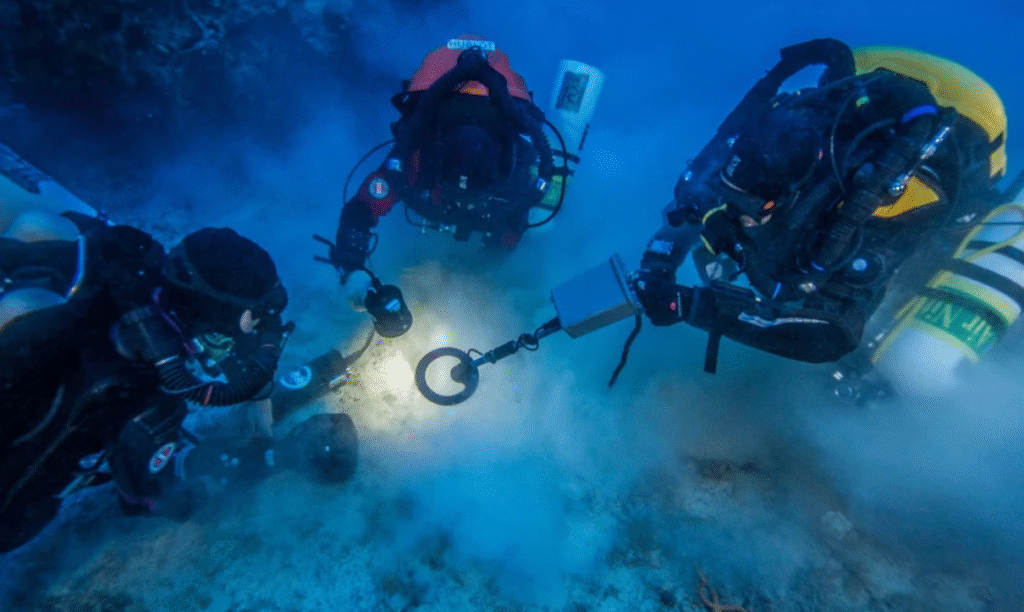

Traditionally, inspections were carried out by divers or remotely operated vehicles (ROVs). While effective, they had limitations:

- Risk to divers: Working under hulls is dangerous due to limited visibility, propeller proximity, and entrapment risks.

- High costs: Daily diver operations and safety measures add significant expenses.

- Time delays: Surveys can take hours or days, extending vessel downtime.

- Coverage gaps: Shadowed areas or complex geometries often remain poorly inspected.

These challenges paved the way for Drone Hull Inspections to disrupt the industry.

What are Drone Hull Inspections?

Think of drones as your remote-controlled eyes that never blink. Drone Hull Inspections involve deploying air or underwater drones equipped with cameras, sonar, and sensors to scan every inch of a ship’s hull.

Two main types are used:

- Aerial drones: Fly above the waterline to inspect topsides, coatings, and stern gear exposed to air.

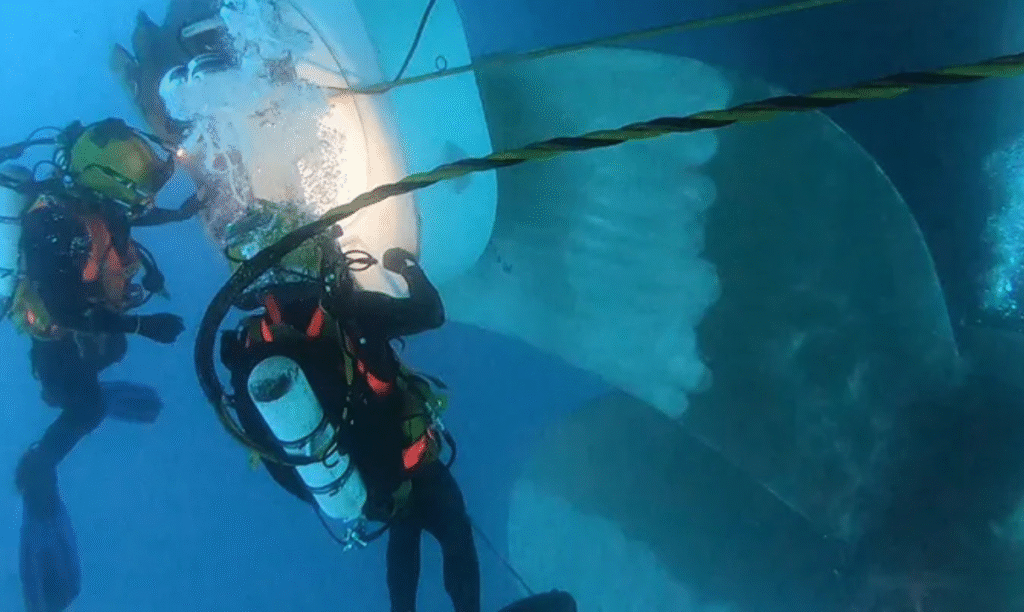

- Underwater drones/ROVs with drone interfaces: Navigate underwater to capture the submerged portions of the hull, bilge keels, strakes, and difficult recesses.

With drones, owners get high-definition videos, photos, and even 3D hull models before cleaning begins.

How Drone Hull Inspections Work Step-By-Step

Here’s how the process typically goes:

- Drone Deployment: An Aerial or underwater drone is deployed near the vessel, often straight from the quayside or small support boats.

- Hull Mapping: The drone uses cameras or sonar to map fouling and damage.

- Live Feed Analysis: Operators view live streams in real time, taking instant notes.

- Data Storage: Recordings are logged for compliance and upcoming maintenance planning.

- Decision Making: Cleaning frequency, method, and scope are determined.

By the time divers or cleaning robots begin, you already know the exact fouling hotspots—like a treasure map pointing to the gold of efficiency savings. Also, read about Underwater hull cleaning in France

Key Benefits of Drone Hull Inspections

The advantages of adopting drone-based inspection are compelling:

- Safety First: No divers exposed to confined spaces or entanglement risks.

- Faster Turnaround: Entire hull scanned in hours instead of days.

- Cost-Efficiency: Lower manpower requirements and reduced vessel downtime.

- Regulatory Alignment: Better compliance documentation for IMO and MARPOL biofouling standards.

- High Accuracy: Detects even micro-scale fouling and coating wear using advanced imaging.

Simply put, Drone Hull Inspections are to hull care what X-rays are to medicine—non-invasive, accurate, and essential.

⚓ Expert Underwater Hull Cleaning with Marine Super Cargo 🌊

— Marine Super Cargo (@Marinsupercargo) September 19, 2025

A clean hull means better performance, lower fuel use, and smoother voyages. Marine Super Cargo offers top Underwater Hull Cleaning to keep your vessel efficient, compliant, and ready for every operation. pic.twitter.com/sVKAUCytuS

Real-World Challenges in Drone Hull Inspections

Like all new technologies, challenges exist:

- Visibility limits: Murky port waters can affect image clarity.

- Battery life: Underwater drones may need frequent charging.

- Skill requirements: Operators need technical training for effective use.

- Initial cost: Equipment purchase or rental costs can be steep.

Despite these, the ROI is consistently positive compared to traditional methods.

Compliance and Environmental Benefits

Global regulators increasingly view hull fouling as a serious risk. It not only increases emissions but also spreads invasive marine species.

- IMO Guidelines for Biofouling (2011): Recommend niche inspection with drones for precision.

- MARPOL Annex V: Waste from cleaning must be controlled, making pre-cleaning inspections vital for targeted approaches.

- IMCA Guidance: Recognizes ROVs and drones as safe alternatives.

- IAPH Initiatives: Ports are beginning to support drone technologies for sustainable shipping.

By improving fouling detection, Drone Hull Inspections enhance environmental accountability.

Innovations in Drone Hull Inspections

Technology is moving fast. Key innovations include:

- AI-Powered Image Recognition: Algorithms that instantly identify fouling species.

- 3D Digital Twin Models: Create exact hull replicas with fouling levels simulated.

- Multi-sensor drones: Using sonar, thermal cameras, and laser scanning to cover blind spots.

- Autonomous Pathing: Drones that self-navigate bilge areas and return automatically when power runs low.

These advances ensure that Drone Hull Inspections won’t just remain a tool but become the gold standard for pre-cleaning checks.

The Cost-Saving Argument

Investing in drones can feel expensive upfront—but think long term:

- Reduced diver days: Saving $5,000–$10,000 per docking cycle.

- Faster decision-making: Avoiding unnecessary full-hull cleaning projects.

- Lower biofouling penalties: Fuel savings reduce CO2 reporting liabilities under IMO’s CII (Carbon Intensity Indicator) regulations.

- Extended coating life: Prevents over-cleaning that wears protective paints.

It’s like buying a top-quality calendar—you spend more upfront but avoid costly scheduling mistakes later.

Operator Best Practices

To maximize benefits, operators are adopting these best practices:

- Conduct drone scans at least twice annually in high-fouling waters.

- Integrate drone data with predictive maintenance software.

- Use drones to document compliance with IMO and MARPOL audits.

- Share inspection records with cleaning vendors for precise job planning.

- Engage trained operators certified under IMCA safety standards.

This way, Drone Hull Inspections become not just inspections, but decision-making tools for the entire fleet.

Case Study: Container Vessel Success

A container ship operator trading between Singapore and Australia dealt with recurring fines for invasive hull fouling. After switching to Drone Hull Inspections, the operator pinpointed exact fouling hotspots around bilge strakes and sea chest recesses. By targeting cleaning based on drone data, they reduced downtime by 40% and cut $220,000 annually in additional fuel expenses.

This case reinforces how drones aren’t a gimmick—they’re a tangible cost-control and compliance tool.

Future of Hull Inspections

Looking ahead, drones will shape the next decade of marine maintenance:

- Autonomous AI-driven drones docking to hulls for continuous monitoring.

- Drone swarms performing coordinated underwater surveys.

- Integration with blockchain compliance logs for instant reporting to port authorities.

- Biofouling-focused drone coatings themselves (to prevent settlement during long inspections).

In short, Drone Hull Inspections are moving from innovation to necessity.

Conclusion

Hull inspections before cleaning are critical, and drones are transforming this space by making them safer, faster, and more cost-effective. Three things stand out:

- Traditional diver inspections are riskier, slower, and more expensive.

- Drones provide safer, high-accuracy hull data for targeted cleaning.

- The future of hull inspections is digital, autonomous, and regulation-friendly.

To safeguard your fleet’s compliance, save money, and lower risk, partner with trusted experts like CleanShip.co for efficient and sustainable solutions tailored to your needs.

FAQs:

Q1. Are drone hull inspections safe in poor visibility waters?

Yes, many drones are equipped with sonar and thermal sensors that provide clear images even in murky port waters.

Q2. Can drones replace divers completely?

Not always. Drones handle inspection, but divers may still be required for specific cleaning or repairs post-inspection.

Q3. How much time do inspection drones save compared to divers?

Typically, drones complete full inspections in under half the time divers need, saving vessel downtime significantly.

Q4. Will inspection drones help with regulatory compliance?

Yes, they offer accurate documentation for IMO, MARPOL, and local port requirements, enhancing audit readiness.

Q5. What’s the future trend for drone inspections in shipping?

Expect AI-driven, autonomous drones with multi-sensor capabilities and seamless integration into fleet performance monitoring.