Palm oil tank cleaning represents one of the most demanding challenges in maritime cargo operations. After transporting palm oil, vessel tanks require thorough to ensure cargo integrity for subsequent shipments. The residue left by palm oil can solidify quickly, creating stubborn deposits that compromise tank cleanliness and violate MARPOL regulations.

At Marine Super Cargo, we specialize in comprehensive tank cleaning solutions that meet international maritime standards. demands specialized knowledge of both the cargo properties and IMO compliance requirements.

Understanding Palm Oil Residue Challenges

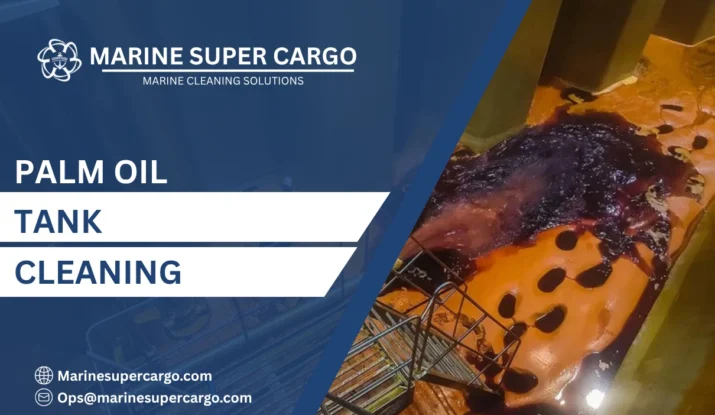

Palm oil solidifies at approximately 35°C, creating waxy deposits along bulkheads, frames, and structural members throughout the cargo space. These deposits accumulate heavily on the port and starboard sides, particularly in areas with reduced circulation. The bow and stern sections often harbor the most persistent residue due to temperature variations during voyage.

The viscous nature of palm oil means standard cleaning methods prove inadequate. Palm oil tank cleaning requires elevated temperatures and specialized detergents to break down these stubborn deposits effectively. Without proper procedures, vessels risk cargo contamination and commercial disputes.

MARPOL Annex I Compliance Requirements

MARPOL Annex I governs the prevention of oil pollution from ships. Palm oil tank cleaning operations must ensure proper waste management and discharge procedures. All residues, washings, and slops must be retained onboard for appropriate disposal at reception facilities.

The IMO MEPC guidelines specifically address vegetable oil transportation and subsequent cleaning operations. Vessels must maintain detailed records of procedures, including volumes of washings retained and disposal methods employed.

Effective Palm Oil Tank Cleaning Methods

Pre-Heating Phase

Before commencing palm oil tank cleaning, heating the cargo space to 60-70°C proves essential. This temperature range liquefies solidified palm oil deposits, allowing effective removal. Heating coils along the tank bottom and sides facilitate uniform temperature distribution throughout the space.

Hot Water Washing

High-pressure hot water washing forms the foundation of effective. Water temperatures exceeding 80°C, combined with strategically positioned Butterworth machines, dislodge residue from all surfaces. The forward and aft positions require special attention during this phase.

Chemical Treatment

Specialized alkaline detergents enhance efficiency. These formulations emulsify oil residues, preventing re-deposition on cleaned surfaces. Marine Super Cargo utilizes biodegradable cleaning agents that meet environmental regulations while delivering superior results.

Ventilation and Inspection

Following the washing cycles, thorough ventilation removes residual vapors. Inspection teams verify cleanliness standards throughout the cargo space, checking frames, stringers, and heating coils for remaining deposits. This critical step ensures readiness for the next cargo.

Safety Protocols During Cleaning Operations

Palm oil tank cleaning involves multiple hazards requiring strict safety measures. Enclosed space entry procedures must follow SOLAS requirements, with continuous atmospheric monitoring for oxygen levels and toxic gases. Personnel conducting operations must wear appropriate protective equipment and maintain communication with deck supervision.

The slippery nature of palm oil residues increases fall risks. Non-slip footwear and secured working platforms prevent injuries during activities. Hot water operations demand thermal protection to prevent scalding incidents.

Time and Resource Management

Efficient palm oil tank cleaning typically requires 24-48 hours depending on vessel size and residue quantity. Proper planning ensures adequate freshwater supplies, heating capacity, and disposal arrangements at the discharge port. Delays in directly impact vessel scheduling and commercial performance.

Marine Super Cargo provides expert tank cleaning services that optimize turnaround times while maintaining exceptional cleanliness standards. Our experienced teams understand the urgency of vessel operations and deliver reliable results consistently.

Documentation and Record Keeping

Comprehensive documentation of palm oil tank cleaning operations satisfies regulatory requirements and provides evidence during cargo surveys. Records should include cleaning methods employed, chemicals used, water volumes consumed, and waste disposal details. These documents protect vessel operators during commercial disputes and port state inspections.

Frequently Asked Questions

Q1: How long does palm oil tank cleaning typically take?

Complete palm oil tank cleaning requires 24-48 hours depending on cargo residue quantity and vessel heating capacity.

Q2: What temperature is needed for effective palm oil removal?

Tanks should be heated to 60-70°C before washing, with water temperatures exceeding 80°C during cleaning operations.

Q3: Can palm oil residues be discharged overboard?

No, MARPOL Annex I prohibits overboard discharge. All washings must be retained onboard for proper disposal ashore.

Q4: What chemicals work best for palm oil tank cleaning?

Alkaline-based biodegradable detergents specifically formulated for vegetable oil residues deliver optimal results while meeting environmental standards.

Q5: Why is inspection important after palm oil tank cleaning?

Thorough inspection ensures complete residue removal, preventing cargo contamination and commercial disputes during subsequent voyages.

Partner with Marine Super Cargo for professional palm oil tank cleaning services that ensure vessel readiness and regulatory compliance.