Imagine a world where hull cleaning requires no divers, no cumbersome manual labor, and no risks to human life—just fleets of intelligent robots silently scrubbing ships beneath the waterline. This isn’t science fiction anymore; it’s the rapidly approaching reality of Autonomous In-Water Cleaning.

These robotic systems promise to transform how operators maintain their vessels. Instead of dreading costly dry-docks or dangerous diver-led operations, ship owners will soon rely on robotic fleets working around the clock—cleaning faster, safer, and cleaner than ever before.

In this article, we’ll uncover what autonomous in-water cleaning technologies mean for the future of hull cleaning, their implications for compliance and cost, and how they’ll reshape maritime sustainability.

The Growing Need for Smarter Cleaning

Hull fouling has always haunted ship operators. A layer of slime, barnacles, or algae may seem insignificant, but its impact is staggering:

- Biofouling increases drag, forcing engines to burn more fuel—sometimes up to 20–30% more.

- Fouling adds millions to OPEX, directly hurting profitability.

- Invasive species carried on hulls disrupt ecosystems, attracting heavy regulatory scrutiny.

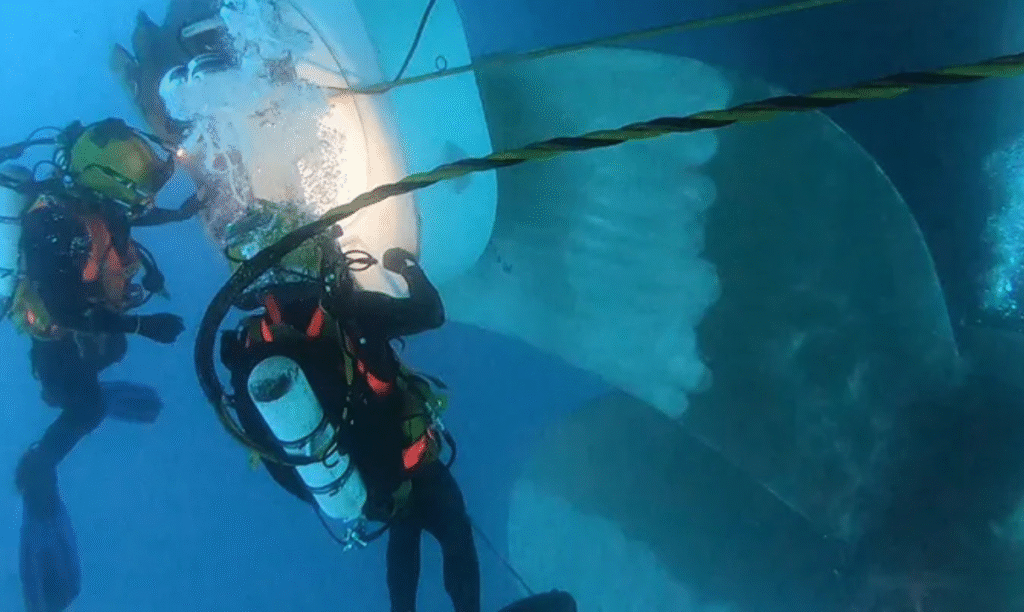

Today’s manual cleaning and diver-dependent methods are risky, labor-intensive, and inefficient. The answer lies in scalable, automated fleets—Autonomous In-Water Cleaning is set to become the industry’s game-changer.

What is Autonomous In-Water Cleaning?

At its core, Autonomous In-Water Cleaning is the use of robotic systems and AI-enabled machines that perform hull cleaning without human divers. These systems:

- Use sensors, cameras, and navigation tools to scan hull surfaces.

- Employ brushes, cavitation jets, or microbubble technology to remove fouling.

- Operate remotely or completely autonomously, often powered by pre-programmed cleaning routes.

- Collect and filter debris, ensuring compliance with MARPOL Annex V disposal rules [Marine Insight – MARPOL Convention].

Think of them as “Roombas of the sea,” tirelessly working around the ship’s underwater hull, ensuring efficiency stays intact.

Key Advantages of Autonomous Cleaning

- Safety First: No risk to divers working in confined and hazardous underwater zones.

- Lower Costs: Reduced need for human manpower and expensive emergency cleanings.

- Operational Continuity: Ships can be cleaned while alongside berth or during short port stays.

- Environmental Compliance: Collected fouling debris avoids biosecurity violations under IMO Biofouling Guidelines.

- Data-Driven Maintenance: Real-time inspection data creates digital hull records linked with blockchain.

Instead of reactive cleaning, autonomous fleets create a regime of continuous, preventive care.

⚓ Expert Underwater Hull Cleaning with Marine Super Cargo 🌊

— Marine Super Cargo (@Marinsupercargo) September 19, 2025

A clean hull means better performance, lower fuel use, and smoother voyages. Marine Super Cargo offers top Underwater Hull Cleaning to keep your vessel efficient, compliant, and ready for every operation. pic.twitter.com/sVKAUCytuS

Technology Behind Autonomous In-Water Cleaning

The technology stack includes:

- AI Navigation: Algorithms allow robots to map hulls, recognize fouling spots, and adjust cleaning motions automatically.

- Sensors & Cameras: Provide high-definition visual and sonar imaging for monitoring and post-cleaning verification.

- Eco-Friendly Cleaning Tools: Neutral brushes or cavitation that clean effectively without damaging antifouling coatings.

- Waste Capture Systems: Built-in filtration ensures all biofouling waste is collected for safe disposal under MARPOL Annex V standards.

- Cloud Integration: Cleaning data and reports are uploaded in real time, accessible globally by owners or port authorities.

This combination ensures operational excellence with minimal supervision.

Compliance and Regulations

Regulations increasingly demand cleaner hulls and tighter documentation:

- IMO’s Biofouling Guidelines (2011): Strongly recommend preventive approaches, not reactive cleaning.

- MARPOL Annex V: Hull cleaning debris can’t be dumped back into the ocean. Disposal protocols are mandatory.

- IAPH Standards: Encourage global ports to adopt cleaner, digitally documented practices.

- IMCA Guidelines: Support diver-free alternatives for safety and standardization.

By aligning with these directives, fleets using Autonomous In-Water Cleaning avoid compliance risks and hefty port penalties.

Future: Fleets of Cleaning Robots

Today, single autonomous cleaning robots exist. Tomorrow, coordinated fleets will:

- Work in swarms to clean entire hulls within a few hours.

- Self-schedule around vessel port calls, optimizing time and energy use.

- Communicate with hull performance monitoring systems to identify fouling severity.

- Integrate predictive AI software for just-in-time cleaning before performance dips.

This evolution will resemble coordinated drone fleets, but underwater—collaborating like schools of fish with a singular mission: fuel efficiency and compliance.

Real-World Adoption

Several pioneering companies have already trialed robotic cleaning technologies:

- Early prototypes proved effective at removing biofilms on coatings.

- Commercial models now include waste capture and data-logging capabilities for reporting.

- Partnerships with ports like those outlined by IAPH are driving quicker adoption across busy hubs.

Case Example: A tanker fleet operating between Europe and Asia introduced pilot Autonomous In-Water Cleaning units. In one year:

- Fuel efficiency improved by 12%.

- CII scores rose significantly, helping compliance.

- Port inspections were expedited thanks to access to digital records.

- Annual savings reached nearly $500,000 across the fleet.

Cost Savings vs. Initial Investment

Critics argue automation is expensive, but the ROI is rapid:

- Fuel efficiency gains cover robotics investment within 12–18 months.

- Reduced manpower and diver costs generate ongoing OPEX savings.

- Continuous cleaning prevents damage to coatings, extending repaint cycles.

It’s like upgrading from regular car washes to self-cleaning paint—initial cost is noticeable, but the long-term benefits are undeniable.

Environmental Rewards

Beyond compliance, autonomous cleaning has an even bigger impact:

- Reduced GHG emissions through improved hydrodynamics.

- Significant cutback in the spread of invasive marine species across ports.

- Better documentation of cleaning waste ensures adherence to MARPOL standards.

- Supports IMO’s decarbonization mission by directly improving vessel efficiency.

Green credentials are no longer optional—Autonomous In-Water Cleaning provides verifiable environmental proof.

Innovations on the Horizon

The future is not just robots but intelligent fleets:

- Bio-Sensor Integration: Robots that assess fouling organisms at a species level.

- Digital Twin Integration: Linking hull cleaning data with ship digital twins for predictive modeling.

- Self-Healing Coatings & Robots: Intelligent coatings designed to work alongside cleaning robots for low-friction synergy.

- Global Record Networks: Blockchain-based verification systems storing every cleaning event for regulators and owners alike.

The future is autonomous, predictive, and fully sustainable.

Best Practices for Adopting Autonomous Cleaning

- Start with hybrid approaches—combine human inspections with robotic cleaning trials.

- Ensure regulatory compliance with debris recovery protocols.

- Train crews to collaborate with robotic cleaning fleets, interpreting reports for performance assessments.

- Integrate cleaning records with digital compliance platforms.

- Collaborate with ports supporting robotic cleaning initiatives.

By planning carefully, operators gain the full benefits with minimal transitional challenges.

Conclusion

The future of hull fouling control is clear: diver-led cleaning is giving way to robotic fleets. Autonomous In-Water Cleaning is safer, faster, greener, and more cost-effective.

Key takeaways:

- Autonomous cleaning eliminates risks and inefficiencies of diver operations.

- Compliance, sustainability, and transparency are inherently stronger with digital robotic fleets.

- Return on investment is rapid, with long-term fuel and OPEX savings.

To make the most of this revolution, partner with innovative leaders like CleanShip.co, who are at the cutting edge of sustainable cleaning solutions.

FAQs:

Q1. How does autonomous in-water cleaning differ from diver cleaning?

Autonomous cleaning uses robotic systems to safely and efficiently clean hulls, doing so continuously with waste capture, unlike diver-dependent manual scrubbing.

Q2. Is the technology already available commercially?

Yes, several early models are in use today, though large-scale autonomous cleaning fleets are still being developed and tested.

Q3. Does autonomous cleaning damage hull coatings?

No, modern robots use gentle brushes, cavitation jets, or microbubbles designed to clean without stripping protective antifouling coatings.

Q4. How does it help with compliance?

Digital logs and waste capture ensure MARPOL Annex V compliance and provide transparent records for IMO and port authorities.

Q5. What’s the biggest innovation coming in robotic cleaning fleets?

Fleet-level autonomy integrated with predictive AI and digital twin technology—allowing hull care to become fully automated and preventive rather than reactive.