If ships could speak at the end of every charter, their stories would be less about the storms survived and more about the arguments they sparked between owners and charterers. Few conflicts in shipping generate as much tension, financial strain, and legal wrangling as hull condition disputes.

Why? Because the hull is the vessel’s foundation. Its condition shapes efficiency, compliance, cost, and reputation. When owners and charterers see that condition differently—or disagree on who is responsible for maintenance or damages—things can escalate fast.

This article explores why hull disputes happen, the stakes involved, and how owners and charterers can navigate them without sinking relationships or profits.

Why Hull Condition Disputes Matter

In theory, contracts should solve everything. In practice, hull condition disputes emerge because the hull is under constant assault from seawater, fouling organisms, and wear from voyages. Operators want maximum vessel efficiency; owners want to protect their asset. When expectations clash, disputes follow.

Think of it like renting a car. The renter wants reliability at low cost; the owner wants the car returned in pristine shape. Add saltwater, global compliance rules, and millions of dollars at stake, and you’ve got a recipe for conflict.

These disputes matter because they lead to:

- Unexpected repair costs

- Delays in charter schedules

- Compliance violations under IMO and MARPOL rules

- Damaged business relationships

- Costly arbitration or court proceedings

Common Causes of Hull Condition Disputes

1. Fouling and cleaning responsibilities

Charterers may claim the owner failed to deliver a clean hull, while owners argue fouling worsened during charter operations.

2. Paint damage or coating failure

Improper hull cleaning or high-pressure washing can strip protective coatings. Who pays becomes the core tension.

3. Corrosion exposed during charters

Owners argue corrosion is a long-term result; charterers claim it worsened due to misuse or delayed maintenance.

4. Fuel efficiency disagreements

If drag from fouling increases fuel burn, charterers may demand compensation, citing reduced efficiency clauses.

5. Lack of clear inspection protocols

When entry and exit reports don’t align, disputes over condition reports are inevitable.

The Financial Impact of Hull Condition Disputes

Hull condition disputes aren’t just arguments; they directly affect your bottom line.

- Legal costs: Arbitration and court fees can reach six figures.

- Charter downtime: Disputes can stall vessel availability.

- Repair bills: Dry-docking, repainting, and coating applications demand millions in the worst cases.

- Operational loss: Fuel inefficiency drains revenue even before disputes are settled.

- Insurance complications: Claims may be delayed or denied amid unresolved liability.

Viewed differently, a dispute over hull condition can be more expensive than preventive maintenance across multiple charters. Read also about underwater hull cleaning in Cochin.

How Contracts Address Hull Condition

Most disputes come down to clauses in the charter party agreement. Standard forms like BIMCO often dictate hull care responsibilities. Yet ambiguity is common.

Owners must:

- Deliver a seaworthy vessel with a fit hull.

- Maintain protection systems and coatings.

Charterers must:

- Avoid damage from cargo operations.

- Respect hull cleaning cycle requirements.

- Return the vessel in a similar condition (excluding normal wear and tear).

But when “normal wear” is interpreted differently, hull condition disputes arise quickly.

Case Study: A High-Stakes Dispute

A bulk carrier operating under time charter developed heavy fouling on a Pacific loop. Charterers blamed the owner for failing to deliver a clean hull at the start. Owners countered that the charter extended into known fouling regions. Both sides pointed fingers, delaying operations.

The matter escalated to arbitration. Ultimately, both sides shared costs—an outcome that neither party considered “fair.” This case highlights how vague clauses and weak inspections can escalate into costly stalemates. Learn more

Compliance and Regulatory Context

Hull condition isn’t just a matter of owner-charterer relationships; it also intersects with global compliance.

- IMO guidelines emphasize fuel efficiency and reduced greenhouse gases, tying directly to hull performance.

- MARPOL Convention sets binding emission limits, making fouling-caused inefficiencies a compliance risk.

- IMCA issues protocols on underwater inspections and hull safety monitoring.

- IAPH port authorities now scrutinize hull conditions for sustainability ratings.

Failing to address hull cleaning and coatings exposes not just legal risk, but also global compliance fines.

✅ 4 Things to Check for Safety at Sea pic.twitter.com/dAxhJQ2i6U

— Marine Super Cargo (@Marinsupercargo) September 14, 2025

Preventing Hull Condition Disputes

The best way to win is not to fight in the first place. Preventive strategies include:

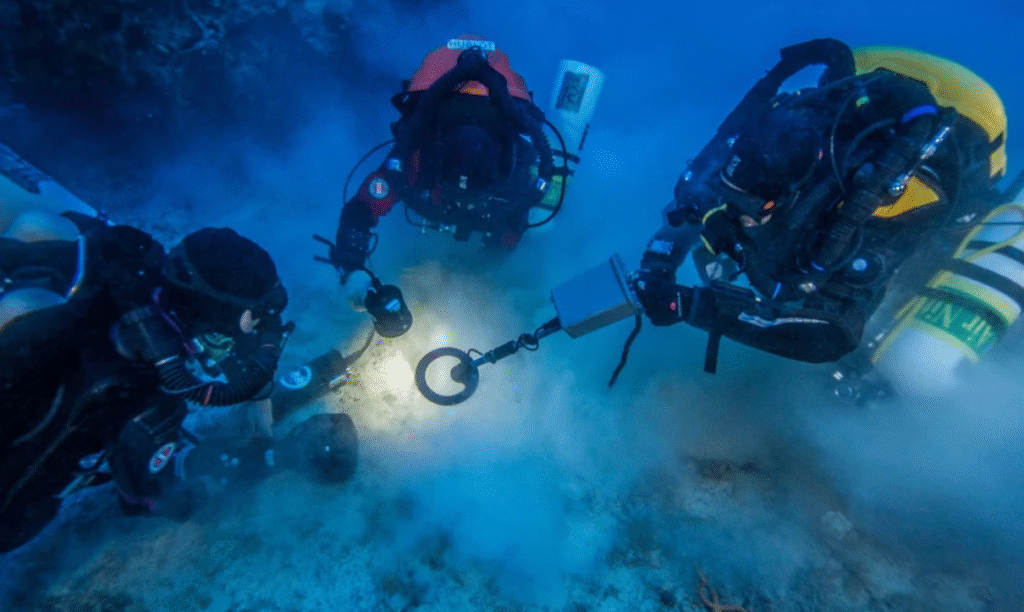

- Clear pre-charter inspections with signed condition reports and photographs.

- Defined cleaning cycles are agreed upon in charter contracts.

- Independent third-party surveys to settle disagreements before they escalate.

- Digital hull monitoring tools that track coating degradation and fouling trends.

- Collaboration, not confrontation—both parties benefit when hull conditions are managed proactively.

Best Practices for Ship Owners

- Deliver vessels with documented hull certificates.

- Invest in quality coatings and fouling-resistant paints.

- Use certified hull cleaning providers to avoid accusations of improper practices.

- Keep a digital log of cleanings, inspections, and repairs to reference during disputes.

Best Practices for Charterers

- Document hull condition upon receipt of the vessel.

- Operate vessels within recommended fouling management guidelines.

- Communicate concerns early, before inefficiencies spiral.

- Share responsibility for mid-voyage cleaning where beneficial.

Being proactive keeps operations smooth and relationships intact.

The Role of Technology in Reducing Disputes

Technology is turning hull condition disputes from endless debates into data-driven decisions.

Examples include:

- Hull performance monitoring: Sensors track fuel consumption and fouling.

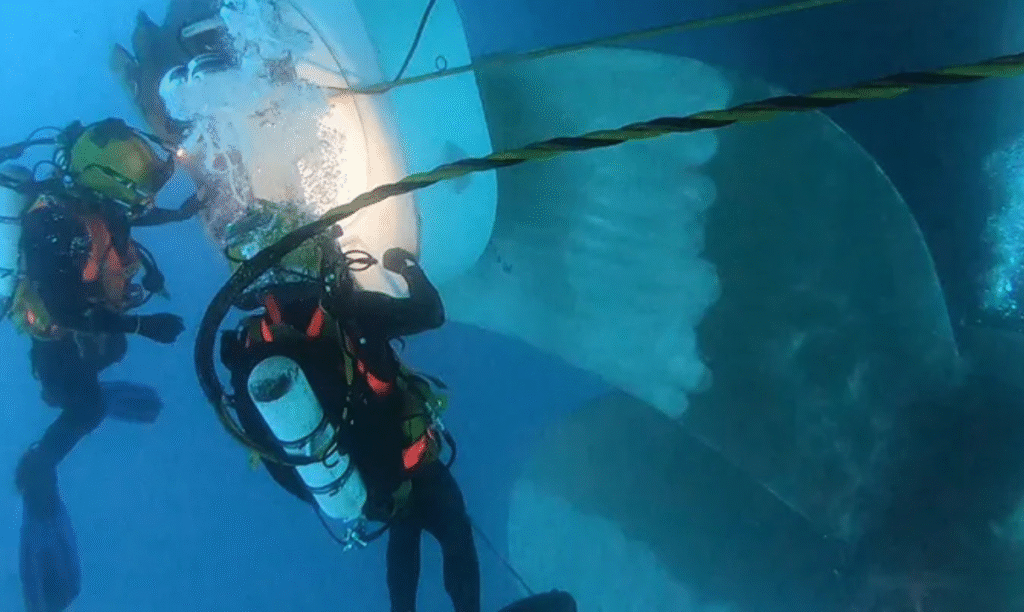

- ROV inspections: Remote-operated vehicles provide unbiased imagery of hull condition.

- AI predictive models: Forecast fouling growth and coating degradation.

- Blockchain contracts: Store tamper-proof hull data for reference in disputes.

These innovations increase transparency—and reduce room for finger-pointing.

Future of Hull Condition Disputes

As environmental rules tighten, expect more disputes linked to efficiency and emissions. Forward-thinking owners and charterers will need to use digital records, real-time monitoring, and smart contracts to avoid unnecessary blame games.

The future of hull condition disputes isn’t about winners and losers; it’s about sustainable collaboration in a heavily regulated industry.

Conclusion

Hull condition disputes between owners and charterers are often rooted in unclear roles, poor inspections, and responsibility gaps. But they can be prevented with three proactive steps:

- Use clear inspection records and independent surveys.

- Align hull cleaning and coating maintenance with compliance.

- Embrace technology-driven monitoring for transparency.

Protecting vessel integrity isn’t just about avoiding conflicts—it’s about safeguarding profits, compliance, and partnerships. For sustainable hull care and expert support, rely on solutions from CleanShip.co.

FAQs:

Q1. Why do hull condition disputes happen so often?

Because fouling, corrosion, and coating failures create gray areas between owner responsibility and charterer use, disagreements are frequent.

Q2. Can charter party contracts fully prevent disputes?

Not always. Clearer wording helps, but differences in interpretation often spark conflicts after deliveries and voyages.

Q3. How does hull condition affect compliance?

Poor hull condition raises drag and fuel burn, risking IMO carbon efficiency standards and MARPOL pollution targets.

Q4. What role do inspections play in avoiding disputes?

Inspections recorded at handover and redelivery provide evidence, reducing reliance on memory or biased claims during conflicts.

Q5. What is the best long-term solution to hull condition disputes?

Digital monitoring, independent surveys, and shared responsibility ensure transparency, cost savings, and fewer legal arguments.