When we talk about ships gliding across oceans, most people imagine smooth steel hulls cutting effortlessly through water. But ask any ship operator, and they’ll tell you the reality is less elegant. Beneath the surface, hulls often gather passengers that no crew invited—barnacles, algae, and other marine organisms. This silent accumulation, known as fouling, eats away at efficiency. The most critical concern? The fouling impact on ship speed.

In this article, we’ll walk through a real-world case study where excessive fouling led to significant speed loss, ripple effects on operations, and lessons that every ship owner, operator, and manager must take seriously.

Understanding Fouling: The Silent Drag

Think of a racing athlete trying to run underwater in heavy boots. That’s what excessive fouling does to a ship. While it may sound like just an exterior nuisance, fouling has a domino effect: increased drag, higher fuel consumption, delays, increased emissions, and compliance headaches linked to environmental regulations such as MARPOL under IMO guidelines.

Fouling impact on ship speed is not a mere technical issue—it’s a business challenge, a regulatory risk, and an environmental concern all at once.

The Case Study Scenario

A bulk carrier operating in tropical waters became the subject of this case study. Despite being on schedule for dry-docking only the year before, the vessel suffered visible speed degradation over six months at sea. The vessel manager noticed average speed slipping a full knot below the charterparty obligation.

- Ship type: Panamax bulk carrier

- Route: Southeast Asia to the Middle East

- Hull cleaning schedule: Last completed 11 months prior

- Observed issue: Speed loss of 1.1 knots at optimal RPM

- Effect: 12% higher fuel consumption

This fouling impact on ship speed was not just a performance blip. It triggered cascading impacts across cost control, environmental reporting, and schedule commitments.

✅ 4 Things to Check for Safety at Sea pic.twitter.com/dAxhJQ2i6U

— Marine Super Cargo (@Marinsupercargo) September 14, 2025

Technical Anatomy of the Problem

To understand the fouling impact on ship speed, let’s break it down. Fouling increases hull roughness, which in turn increases frictional resistance. Imagine rubbing your hand over sandpaper compared to glass—the difference is drag. Even a thin biofilm can add up:

- Light biofilm: about 1–2% increase in resistance

- Weed fouling: up to 10% resistance

- Heavy barnacle growth: 30–40% resistance

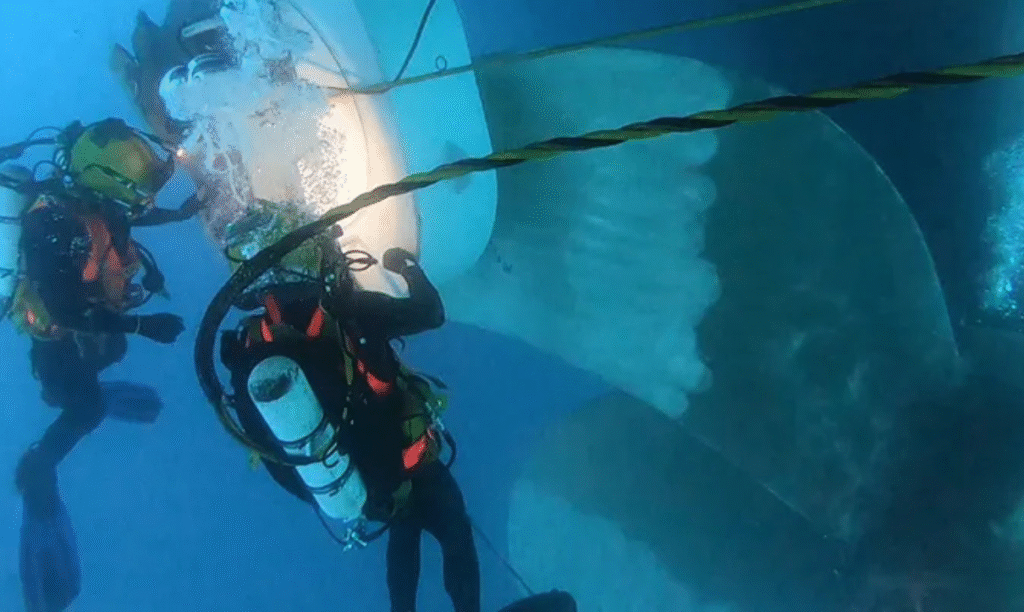

In our bulk carrier case, diver inspection revealed a cocktail of slime and barnacle clusters on the flat bottom. Propeller fouling added to the drag, further cutting propulsive efficiency.

This directly explains the speed loss. To maintain service speed, the engine had to burn more fuel, essentially paying an invisible tax to marine hitchhikers. Also read about underwater hull cleaning in Chochin.

Operational Consequences

The case study shows how fouling impacts on ship speed has ripple effects beyond just cargo delivery delays.

- Charterparty breaches: The vessel risked performance claims from charterers.

- Fuel overheads: A 12% increase in bunker consumption equaled tens of thousands of dollars over six months.

- Compliance challenges: Higher CO₂ emissions per mile conflicted with IMO’s CII (Carbon Intensity Indicator) requirements.

- Schedule slippages: Port calls were delayed, disrupting loading windows.

A problem that started on the hull bottom quickly climbed the ladder to strategic decision-making, affecting contracts, profitability, and compliance.

Human Lessons From Fouling Impact on Ship Speed

One of the key lessons from this case is neglecting proactive cleaning. Just like ignoring regular medical checkups can lead to sudden serious illness, waiting until fouling becomes visible is too late.

The ship manager admitted that commercial pressure to reduce hull cleaning costs led to skipping a mid-cycle underwater inspection. Ironically, the resulting cost of excess fuel was several times higher than the cleaning itself.

This is a powerful reminder: short-term savings pale against the long-term financial and regulatory risks brought by fouling.

Environmental and Regulatory Pressures

The IMO (International Maritime Organization) and other authorities like IMCA (International Marine Contractors Association) and IAPH (International Association of Ports and Harbors) increasingly emphasize hull cleaning as compliance-critical.

- MARPOL Annex VI makes vessel emissions directly tied to hull conditions.

- IMO’s EEXI (Energy Efficiency Existing Ship Index) punishes ships with degraded performance.

- Ports worldwide are introducing restrictions on in-water cleaning unless proven environmentally safe.

So, fouling impact on ship speed is not merely operational inefficiency—it’s a compliance red flag.

The Recovery Measures

The operator decided on immediate intervention. Divers conducted underwater hull cleaning at the port anchorage. Propeller polishing and barnacle scraping restored significant performance, reducing resistance and improving fuel efficiency.

Results after cleaning:

- Speed recovered: ~0.9 knots at standard RPM

- Fuel use dropped by ~10%

- Improved reporting for compliance monitoring

The cost of the intervention was modest compared to the enormous financial drain it reversed.

Strategies to Prevent Fouling Impact on Ship Speed

You cannot stop marine organisms from attaching to hulls, but you can manage their growth smartly. Best practices include:

- Frequent underwater inspections using ROVs or divers.

- Fouling-resistant coatings and advanced anti-fouling paints.

- In-water hull cleaning schedules should be followed before performance loss becomes severe.

- Data-driven monitoring of speed-fuel curves to detect early fouling signs.

- Environmentally compliant cleaning methods to avoid port restrictions while safeguarding ecosystems.

Think of prevention as brushing teeth daily instead of waiting for root canal surgery. Small, timely actions stop major operational pain.

Future Trends in Hull Cleaning

Technology is transforming solutions for mitigating fouling impact on ship speed. Innovations include:

- Robotic hull cleaning systems that can remove slime without harming coatings.

- Nanotechnology coatings offer longer-lasting resistance.

- AI-driven fouling prediction models based on operational routes and sea conditions.

- Port-based eco-friendly cleaning hubs are being developed under IAPH collaborations.

Such trends promise to reduce both operational risk and environmental damage in the years to come.

Key Takeaways

Excessive fouling leading to speed loss is not just a technical mishap—it’s a business, compliance, and environmental challenge. Our case study shows that ignoring hull management costs more in every respect.

Conclusion

The case study reveals three critical lessons:

- Prevention saves money—regular inspection and cleaning cut long-term costs.

- Compliance is inevitable—IMO and port authorities are tightening fouling controls.

- Sustainability matters—efficient hulls reduce emissions and protect oceans.

Managing fouling impact on ship speed demands attention from every operator. Stay ahead of performance loss, choose eco-friendly solutions, and protect your bottom line. For smart, compliant, and sustainable hull care, explore trusted solutions at CleanShip.co.

FAQs:

Q1. How does fouling directly affect ship speed?

The Fouling Impact on Ship Speed is immediate and costly. Marine growth increases drag on the hull, forcing ships to burn significantly more fuel just to maintain their service speed, reducing efficiency and profitability.

Q2. What types of fouling most impact efficiency?

The Fouling Impact on Ship Speed is most severe with barnacles and heavy weed, which create rough surfaces and turbulence. Even thin layers of slime can reduce performance by several percentage points.

Q3. How often should underwater hull cleaning be done?

Inspections are recommended every 4–6 months, with cleaning scheduled before major fouling sets in to minimize the Fouling Impact on Ship Speed and avoid costly operational delays.

Q4. Is underwater hull cleaning allowed in all ports?

No. Many ports restrict cleaning methods that release biomass and coatings. Using eco-safe technologies and containment systems is critical for compliance.

Q5. What is the role of coatings in reducing fouling?

Advanced antifouling paints and nanotech coatings help prevent organism settlement, extend cleaning intervals, and reduce drag, making them essential in limiting fouling impacts on ship performance.