When was the last time your ship had a proper underwater hull cleaning job? If you hesitated before answering, you’re not alone. Many ship owners and operators delay this critical maintenance task until performance drops or inspections loom close. But here’s the truth: keeping your hull clean is not just about appearance—it’s about safety, compliance, efficiency, and long-term cost savings.

Think of your ship’s hull as the lungs of a marathon runner. Any biofouling, like barnacles or algae, acts as an obstruction, making your vessel work harder, consume more fuel, and accelerate wear. Properly planning an underwater hull cleaning job ensures that your ship can breathe, move, and perform at its best.

In this guide, we’ll walk you through everything from pre-cleaning assessments to compliance obligations under IMO and MARPOL, all the way to innovative technologies shaping the future of hull cleaning. Whether you’re managing a container ship, bulk carrier, or tanker, this step-by-step roadmap will help you plan smarter, operate sustainably, and save big.

Why Planning Matters for an Underwater Hull Cleaning Job

Rushing an underwater hull cleaning job is like setting sail without a compass—you might get there, but at what cost? Poor planning often leads to:

- Increased downtime because of unexpected delays.

- Regulatory violations occur if compliance requirements are overlooked.

- Wasted resources due to improper cleaning techniques.

- Fuel inefficiencies that rack up operational costs.

When you plan a cleaning job meticulously, you’re not just ticking a box—you’re safeguarding your vessel, your bottom line, and your environmental responsibilities.

Understanding the Basics: What Is an Underwater Hull Cleaning Job?

An underwater hull cleaning job involves removing biofouling—marine growth like barnacles, algae, and mussels—from a vessel’s submerged surfaces. These organisms cause drag, reduce fuel efficiency, and can spread invasive species across marine ecosystems.

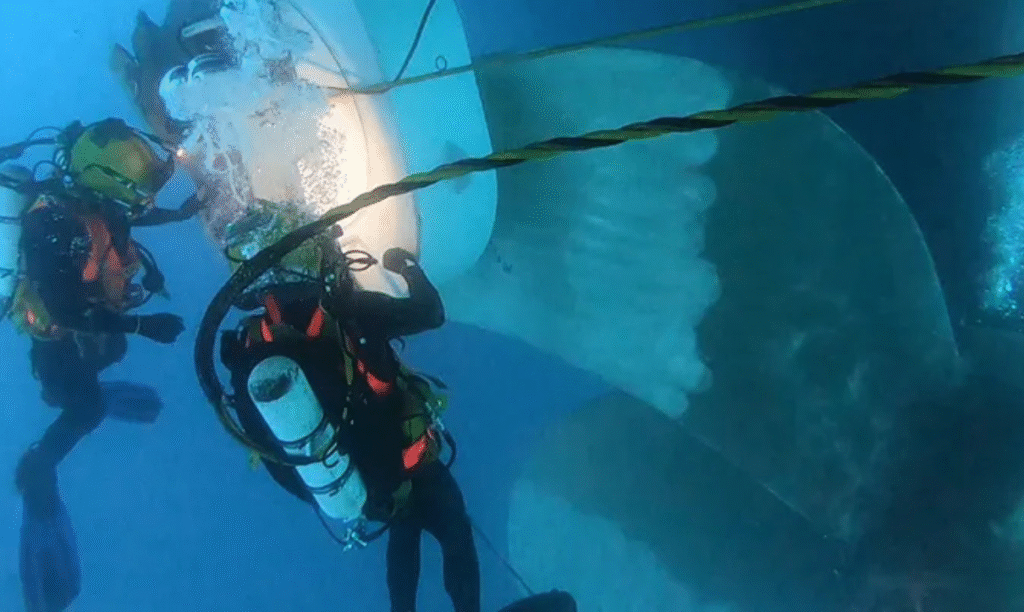

Depending on the vessel and operational cycle, hull cleaning is carried out by specialized divers or remotely operated vehicles (ROVs). Unlike drydocking, it allows cleaning while the vessel remains afloat, minimizing downtime.

Key Benefits of a Well-Planned Underwater Hull Cleaning Job

- Fuel savings of up to 20%. Studies show that even moderate fouling can spike fuel consumption drastically.

- Improved operational efficiency, keeping transport schedules reliable.

- Lower greenhouse gas emissions, in line with IMO decarbonization strategies.

- Extended coating life, by preventing biofouling from breaking down antifouling paints.

- Regulatory compliance, especially under guidelines like MARPOL and the IMO Biofouling Guidelines.

Step 1: Assessing the Hull Condition

Like a doctor examining a patient before surgery, your first step is a detailed hull inspection. Using divers, ROVs, or underwater drones equipped with cameras helps identify:

- Type and extent of fouling.

- Condition of antifouling coatings.

- Damaged or corroded sections of the hull.

- Critical areas like sea chests, propellers, and rudders.

This assessment acts as your blueprint, helping determine cleaning scope, techniques, and resources needed.

Step 2: Choosing the Right Timing

Timing is critical in an underwater hull cleaning job. Wait too long, and fouling becomes harder to remove. Do it too frequently, and you risk premature damage to coatings.

Factors influencing timing:

- Vessel trading routes (tropical waters accelerate fouling).

- Duration between drydockings.

- Regulatory inspections are scheduled in certain ports.

- Fuel consumption trends are monitored through performance data.

Step 3: Selecting the Cleaning Method

Not all hull cleaning methods are created equal. Choosing the right one depends on hull coating, fouling severity, and port regulations.

- Manual cleaning by divers – Flexible, but labor-intensive.

- ROV cleaning units – Safer, reducing diver exposure, but higher upfront cost.

- Brush/kart systems – Highly effective yet may damage coatings if misused.

- Cavitation/hydro-jet cleaning – Advanced, eco-friendly method with minimal coating impact.

Always align your method with IMO and IMCA guidelines to ensure safety and compliance.

Step 4: Addressing Environmental and Compliance Concerns

Every underwater hull cleaning job has environmental consequences if not managed properly. Dislodged organisms and paint particles can spread invasive species or pollute local waters.

Regulatory context to consider:

- IMO Biofouling Guidelines (2011 MEPC.207(62)) encourage best practices to minimize invasive species transfer.

- MARPOL Annex V restricts the disposal of harmful substances into the sea.

- IAPH guidelines emphasize port-level regulations on hull cleaning waste.

Some ports require the capture and treatment of cleaning residues instead of releasing them directly into surrounding waters. Failure to comply not only risks fines but also damages your company’s environmental footprint.

Step 5: Coordinating with Certified Contractors

Working with experienced hull cleaning contractors ensures that your underwater hull cleaning job is executed efficiently, safely, and in compliance with frameworks. Checklist for selecting contractors:

- Valid certifications (IMCA, ISO, or national maritime authorities).

- Proven safety procedures and incident history.

- Operational capacity (divers, ROVs, specialized tools).

- Experience with similar vessel types.

✅ 4 Things to Check for Safety at Sea pic.twitter.com/dAxhJQ2i6U

— Marine Super Cargo (@Marinsupercargo) September 14, 2025

Step 6: Safety Considerations

Hull cleaning is not risk-free. Divers are exposed to hazards like entanglement, decompression issues, and low visibility. Vessel movements in busy ports can also pose risks.

Mitigation strategies:

- Use safety checklists and procedures recommended by IMCA.

- Halt engine or propeller operations during cleaning.

- Provide communications equipment for divers.

- Monitor weather and tidal conditions closely.

Step 7: Future-Proofing with Technology

The future of underwater hull cleaning jobs is shifting toward automation. Innovations include:

- Autonomous hull-cleaning drones guided by AI.

- Ultrasonic antifouling systems prevent fouling rather than removing it.

- Data-driven hull performance monitoring, connecting cleaning frequency with predictive analytics.

Such technologies align with IMO’s long-term emission reduction goals, offering both operational savings and environmental benefits.

Common Mistakes to Avoid in an Underwater Hull Cleaning Job

- Relying on unqualified local contractors for short-term cost savings.

- Ignoring local port regulations on waste handling.

- Performing too aggressive cleaning, damaging antifouling coatings.

- Neglecting propeller polishing as part of the job.

Cost Factors to Consider

The cost of an underwater hull cleaning job depends on vessel size, fouling severity, and the method chosen. While upfront expenses may seem high, remember that a well-timed cleaning can pay for itself many times over in fuel savings.

Factors influencing cost:

- Diver vs ROV services.

- Port accessibility and regulations.

- Frequency of cleaning intervals.

- Fuel prices (higher prices magnify cost savings from efficiency).

Conclusion

Planning an underwater hull cleaning job is much more than ticking off a maintenance routine—it’s a smart investment in efficiency, compliance, and sustainability. Remember these three key takeaways:

- A proper inspection and cleaning strategy can save 10–20% in fuel costs.

- Compliance with IMO, MARPOL, and port regulations avoids fines and ensures sustainable operations.

- Embracing new technologies for biofouling management positions your fleet for the future.

When it comes to environmentally responsible and cost-effective cleaning, consider reaching out to trusted professionals. For reliable solutions, visit CleanShip.co and learn how they can support your fleet’s needs.

FAQs:

Q1. How often should I schedule an underwater hull cleaning job?

Most ships require cleaning every 6–12 months, depending on trading routes, coating type, and water temperatures. Monitoring fuel efficiency data helps determine the best schedule.

Q2. Can underwater hull cleaning damage antifouling coatings?

Yes, aggressive methods may erode coatings. Choosing the correct technique and certified contractors is essential to preserving your hull’s protective paint layers.

Q3. Is underwater hull cleaning allowed in all ports?

No, some ports have strict biofouling waste regulations. Always check IAPH and local authorities’ guidelines before planning cleaning operations.

Q4. What are the environmental benefits of timely hull cleaning?

It reduces fuel consumption, cuts greenhouse gas emissions, and prevents the spread of invasive marine species, aligning with IMO decarbonization targets.

Q5. Are robotic hull cleaners effective compared to divers?

Yes, robotic cleaners are increasingly effective, reducing human risk while offering precise and eco-friendly cleaning, especially for larger vessels on tight schedules.