Hull cleaning is essential for maintaining ship performance, reducing fuel consumption, and avoiding fouling-related damage. But traditional cleaning methods often leave behind chemical residues, paint particles, and invasive species in the water, harming marine ecosystems. This is where Zero-Discharge Hull Cleaning Methods come into play.

Think of them as underwater “vacuum cleaners” that remove fouling while ensuring nothing harmful escapes into the sea. In this article, we explore the technical, environmental, and operational aspects of zero-discharge methods and show why they’re becoming the industry standard.

What Are Zero-Discharge Hull Cleaning Methods?

Zero-discharge hull cleaning methods are specialized techniques that remove fouling, sediments, and debris from a ship’s hull without releasing pollutants into the surrounding waters. Unlike conventional cleaning, which can spread invasive species or toxic substances, zero-discharge systems capture all waste for proper disposal.

Key components of these methods include:

- Capture Systems: Suction devices or containment shrouds attached to cleaning equipment.

- Filtration Units: Multi-stage filters that separate paint particles, biological matter, and sediments.

- Safe Disposal Methods: Onshore facilities that treat and recycle the collected waste safely.

By employing these systems, ship operators can maintain hull performance, comply with environmental regulations, and protect marine ecosystems.

Why Zero-Discharge Methods Are Important

Imagine cleaning a floor but leaving the dirt in the room—it defeats the purpose. Similarly, conventional hull cleaning can pollute oceans, harm marine life, and violate regulations. Zero-Discharge Hull Cleaning Methods prevent these issues while providing operational benefits.

Key reasons these methods matter include:

- Environmental Protection: Prevents the release of copper, zinc, and other toxic substances from antifouling paints.

- Control of Invasive Species: Captures fouling organisms that could spread to new regions.

- Regulatory Compliance: Aligns with IMO biofouling guidelines and MARPOL discharge regulations.

- Cost Efficiency: Reduces fuel consumption, prevents coating damage, and avoids fines or port detentions.

Technical Aspects of Zero-Discharge Hull Cleaning

Zero-discharge systems rely on advanced technology to capture debris without damaging the hull:

- Hydraulic and Pneumatic Suction: Controlled pressure ensures safe debris removal.

- Multi-Stage Filtration: Separates particles by size to prevent environmental contamination.

- Mobility: Devices can be used by divers, remotely operated vehicles (ROVs), or autonomous cleaning robots.

- Real-Time Monitoring: Sensors track water turbidity, debris collection, and cleaning efficiency.

Following guidelines from IMCA and IMO ensures maximum effectiveness while maintaining safety and compliance.

Environmental Benefits

Zero-discharge methods provide significant ecological advantages:

- Protects Marine Life: Prevents toxic substances from reaching fish, coral reefs, and seabed ecosystems.

- Reduces Microplastic Pollution: Paint flakes and debris are captured before breaking into smaller particles.

- Prevents Spread of Invasive Species: Ensures biofouling organisms do not colonize new ports.

- Supports Corporate Sustainability: Demonstrates environmental responsibility for shipping companies.

Case studies indicate that vessels using zero-discharge cleaning methods report a reduced environmental footprint while remaining fully compliant with regulations. Read also about underwater hull cleaning in Ghana

Cost and Compliance Advantages

Although zero-discharge systems require an initial investment, they provide long-term savings:

- Fuel Efficiency: Cleaner hulls reduce drag, leading to fuel savings of up to 15%.

- Port Compliance: Avoids penalties, detentions, or denied entry at environmentally strict ports.

- Hull Longevity: Reduces abrasive wear on antifouling coatings.

- Insurance and Liability: Demonstrates proactive risk management, potentially lowering insurance premiums.

Using certified services like CleanShip.co ensures that operators maintain compliance while optimizing operational costs.

Common Zero-Discharge Methods

Several methods are widely used in the industry:

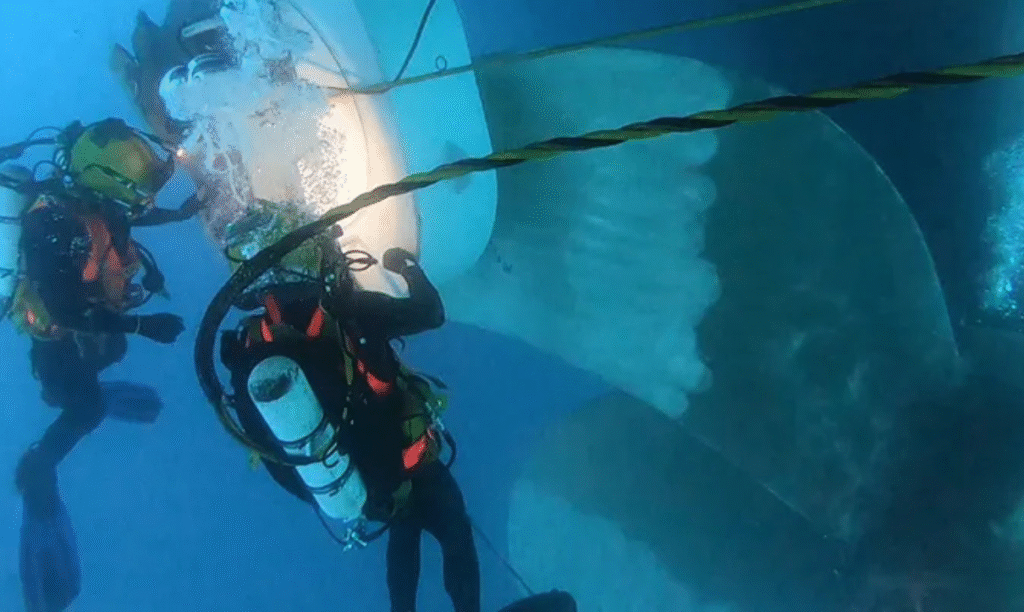

- Containment Systems with Diver Assistance

- Divers use suction units combined with containment shrouds.

- Captures all residues for safe disposal.

- Recommended in ports with strict discharge regulations.

- ROV-Based Cleaning

- Remotely operated vehicles clean hulls with onboard filtration.

- Suitable for deep-draft vessels and hazardous environments.

- Autonomous Cleaning Robots

- Fully automated systems with onboard sediment capture.

- Reduces labor costs and ensures consistent cleaning.

- Vacuum Filtration Suction Units

- High-power suction connected to filtration systems.

- Separates biological matter, paint flakes, and sediments efficiently.

- Onboard Water Treatment Systems

- Ships process collected residues internally.

- Reduces reliance on port facilities and allows multiple cleanings during voyages.

All methods comply with IMO and MARPOL regulations, preventing the release of harmful pollutants.

✅ 4 Things to Check for Safety at Sea pic.twitter.com/dAxhJQ2i6U

— Marine Super Cargo (@Marinsupercargo) September 14, 2025

Case Study: Real-World Impact

A container vessel operating in Southeast Asia implemented zero-discharge cleaning with diver-assisted suction units. Results after one year included:

- 100% compliance with port environmental regulations.

- 15% reduction in fuel consumption due to cleaner hull surfaces.

- No invasive species detected during follow-up inspections.

- Lower hull maintenance costs because of minimal coating damage.

This demonstrates how zero-discharge methods combine compliance, cost efficiency, and environmental stewardship.

Future Innovations

The future of zero-discharge hull cleaning looks promising:

- AI-Enhanced Cleaning: Predicts fouling accumulation and optimizes cleaning schedules.

- Eco-Friendly Coatings: Reduce debris formation, simplifying containment.

- Autonomous ROVs: Fully independent cleaning with onboard filtration and monitoring.

- Integrated Sensor Networks: Tracks environmental impact and cleaning effectiveness in real-time.

These innovations will help shipping companies operate sustainably without compromising efficiency or compliance.

Best Practices for Operators

To maximize benefits:

- Plan Cleaning Ahead: Schedule during favorable tides and in ports with support systems.

- Use Certified Contractors: Partner with companies like cleaniship.co for reliable services.

- Inspect Equipment Regularly: Ensure suction and filtration systems are functioning properly.

- Document Waste Disposal: Maintain records for inspections and audits.

- Train Crew: Proper training ensures safety and method efficiency.

Conclusion

Zero-discharge hull cleaning is now the standard for sustainable shipping. These methods protect oceans, maintain compliance, and offer cost savings.

Key Takeaways:

- Capture and containment prevent pollution and the spread of invasive species.

- Compliance with IMO, MARPOL, and port regulations is ensured.

- Cleaner hulls reduce fuel consumption and maintenance costs.

Partner with CleanShip.co to implement zero-discharge hull cleaning methods efficiently and responsibly.

FAQ:

Q1. What are zero-discharge hull cleaning methods?

Techniques that clean hulls without releasing harmful debris, paint particles, or biofouling into the water.

Q2. Why are they important?

They prevent environmental pollution, control invasive species, and ensure compliance with IMO and MARPOL regulations.

Q3. Can zero-discharge methods save money?

Yes, they reduce fuel costs, minimize coating damage, and avoid fines or port detentions.

Q4. Which vessels benefit most?

All vessels, particularly container ships, tankers, and bulk carriers, in environmentally sensitive ports.

Q5. How do operators implement these methods?

By using certified contractors, trained divers, or ROVs with containment and filtration systems, while maintaining compliance records.