Imagine running a marathon with heavy, mud-caked sneakers. Every step feels twice as hard, energy drains quickly, and your pace suffers. Ships face the same struggle with fouled hulls. Every layer of slime, barnacle, or algae adds drag—turning efficient vessels into fuel-guzzling giants. That’s why finding the right Hull Cleaning Methods is not just routine maintenance—it’s a strategy for operational efficiency, compliance, and cost savings.

In this deep dive, we’ll explore the differences between cleaning coated vs. uncoated hulls, why choosing the right method matters, and how ship owners can balance short-term costs with long-term sustainability.

Why Clean Hulls Matter

A clean ship hull is like a freshly waxed surfboard gliding over waves—smooth, fast, and hydrodynamic. In contrast, a fouled hull behaves more like dragging a raft through a swamp. Surface friction skyrockets, engines strain harder, and fuel bills surge.

Key outcomes of ignoring fouling include:

- Fuel penalties of up to 40% in extreme fouling cases (IMO estimates).

- Increased emissions are making it harder to comply with MARPOL Annex VI.

- Invasive species transfer, risking fines or port restrictions (highlighted by IAPH initiatives).

- Shortened coating life, sending vessels into early dry dockings.

Simply put: hull cleaning may feel like housekeeping, but it’s actually a frontline strategy for profits and compliance.

Coated vs. Uncoated Hulls: What’s the Difference?

When discussing Hull Cleaning Methods, the type of hull coating determines everything—from technique to frequency.

- Coated Hulls

Equipped with Self-Polishing Coatings (SPC) or Fouling Release Coatings (FRCs), these surfaces are designed to resist marine fouling and allow smoother cleaning. Think of them as non-stick frying pans—easier to maintain, resistant to buildup, and longer-lasting. - Uncoated Hulls

Raw steel or poorly protected surfaces with minimal antifouling defense. Cleaning these is like scrubbing food off an old, rusty pan: more effort, more damage risk, and less efficiency overall.

The approach to cleaning must balance protection, cost, and compliance differently for each.

⚓ Get Your Ship Cargo Ready with Marine Super Cargo 🚢

— Marine Super Cargo (@Marinsupercargo) September 12, 2025

Your next voyage begins with a vessel that’s clean, compliant, and cargo-ready. At Marine Super Cargo, we deliver top-quality marine services: pic.twitter.com/3627aoKAZo

Hull Cleaning Methods for Coated Surfaces

Coated surfaces are delicate but more rewarding. Proper techniques maximize ROI on premium coatings like SPCs and silicone FRCs.

- Brush and Disc Cleaning (Diver-based)

Special rotating brushes gently sweep off fouling without damaging coatings. Works best for light fouling. - Soft Robotic Systems

Automated crawlers with soft brushes or water jets adapted for SPC/FRC coatings. These maintain smoothness while minimizing abrasion. - In-Water Hull Grooming

A proactive method using soft pads to prevent fouling from hardening. Best done regularly before heavy buildup. - Controlled Jet Cleaning

Low-pressure water jets that dislodge slime. High pressures are avoided to prevent coating damage.

Benefits include maintaining coating lifespan, compliance with IMO antifouling regulations, and sustaining smoother performance.

Hull Cleaning Methods for Uncoated Surfaces

For uncoated or poorly protected hulls, cleaning is more abrasive and frequent, often with higher risks.

- Steel Brushing & Grinding

Manual diver tools remove encrusted fouling but risk pitting steel surfaces. - High-Pressure Water Jets

At higher pressures, these strip off fouling along with corrosion, but leave hulls exposed. - Abrasive Removal Tools

Mechanical scrapers or rotary polishers clear heavy fouling but accelerate corrosion unless recoated quickly.

In many cases, cleaning uncoated hulls is a temporary fix, buying time until re-coating or dry-docking.

Environmental and Compliance Considerations

Not all Hull Cleaning Methods are equal in the eyes of regulators. IMO’s guidance and regional authorities (such as New Zealand’s strict in-water cleaning restrictions) emphasize minimizing pollution from cleaning debris.

- For coated hulls: Cleaning debris is generally smaller, easier to collect, and far less invasive.

- For uncoated hulls: Cleaning releases rust, heavy biofouling, and toxic residues into the marine environment.

Organizations like IMCA and IAPH urge regular inspections and eco-responsible cleaning, aligning with MARPOL protocols. Compliance isn’t optional—it keeps ships from costly fines and even denies entry at ports.

Cost Comparison: Coated vs. Uncoated Cleaning

| Factor | Coated Hulls | Uncoated Hulls |

|---|---|---|

| Cleaning Frequency | Less frequent, proactive | Frequent, reactive |

| Cleaning Effort | Moderate, low-abrasion | High, abrasive, labor-intensive |

| Impact on Fuel Efficiency | Sustained savings (5–15%) | Limited improvement, penalties return |

| Coating Lifespan | 4–5 years | None—corrosion accelerates |

| Compliance Risk | Low with eco-cleaning methods | High (release of invasive species) |

| Long-term Cost Efficiency | High | Low |

This comparison highlights the critical importance of coatings in defining a cleaning strategy.

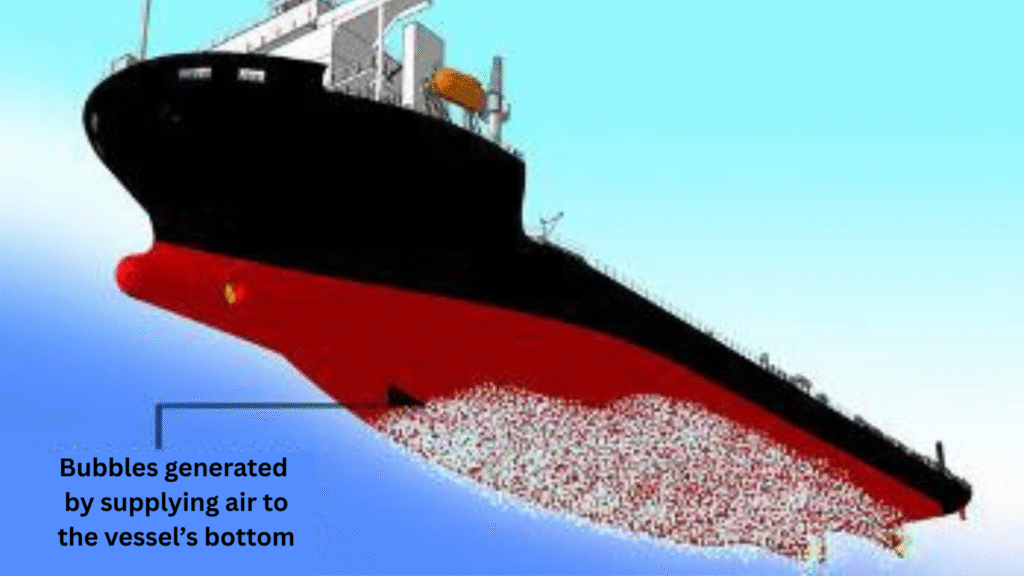

The Role of Technology in Cleaning

Advancements in technology are rapidly transforming Hull Cleaning Methods, making them smarter, safer, and more environmentally responsible. Modern approaches increasingly rely on autonomous underwater robots (AUVs) equipped with high-resolution cameras and sensors, allowing precise cleaning without harming the vessel’s coating.

AI-powered systems now track hull performance, linking Hull Cleaning Methods to fuel efficiency and operational schedules, ensuring cleaning occurs at optimal times. Containment and filtration technologies are being integrated into Hull Cleaning Methods to capture fouling waste, reducing the risk of spreading invasive species and protecting marine ecosystems.

Researchers are also exploring nanotechnology-based surfaces that minimize fouling, which could dramatically reduce the frequency and intensity of Hull Cleaning Methods. As environmental regulations tighten globally, technology-driven Hull Cleaning Methods are set to dominate the maritime sector.

Today’s innovations are shaping the future, making Hull Cleaning Methods more effective, sustainable, and aligned with modern shipping demands.

Practical Tips for Ship Operators

- Match hull cleaning methods to your coating system—avoid abrasive brushes on silicone FRCs.

- Proactively maintain hulls with grooming instead of waiting for heavy fouling.

- Align interventions with IMO antifouling compliance and IAPH biofouling guidelines.

- Monitor hull efficiency digitally (fuel use vs. speed) to schedule cleanings smartly.

- Partner with eco-certified cleaning operators—services like CleanShip.co specialize in sustainable cleaning practices.

Conclusion

Choosing the right Hull Cleaning Methods can make or break operational efficiency.

Here are the three things to remember:

- Coated hulls benefit from gentle, proactive cleaning that preserves long-term efficiency.

- Uncoated hull cleaning is harsher, costlier, and riskier—recoating is the smarter move.

- Proactive, eco-compliant cleaning aligns with MARPOL and IAPH guidelines while cutting fuel penalties.

For sustainable, future-ready hull cleaning strategies, explore trusted solutions at CleanShip.co.

FAQ:

Q1. How often should hull cleaning be done?

It depends on the coating. Coated hulls may need grooming every few months, while uncoated hulls require frequent cleaning due to faster fouling buildup.

Q2. Are in-water hull cleanings always allowed?

No. Some ports restrict them to prevent the spread of invasive species. Always check IMO and regional IAPH biofouling regulations before scheduling.

Q3. Do coatings reduce cleaning costs significantly?

Yes. Quality coatings like SPCs and FRCs cut cleaning frequency, lower labor costs, prolong dock intervals, and reduce fuel penalties.

Q4. Is robotic hull cleaning safer than diver cleaning?

Absolutely. Robotic cleaners reduce diver risk, ensure consistency, and can combine cleaning with inspection and data logging.

Q5. Are uncoated hulls common in shipping today?

No. Most vessels now use at least basic coatings, but poorly maintained or damaged coatings can effectively leave hulls “uncoated.”