The world of shipping is changing faster than ever. Rising fuel costs, stricter environmental regulations, and the battle against marine biofouling have made hull cleaning a top priority for ship owners and operators. In this transformation, one innovation stands out—the Magnetic Crawler Robots.

Imagine sending a machine, much like a stealthy gecko crawling along a wall, to clean your ship’s hull underwater—safe, efficient, and thorough. These robotic crawlers are not just a futuristic vision; they are practical solutions already reshaping how we manage vessel performance and compliance.

In this article, we’ll explore how Magnetic Crawler Robots are revolutionizing hull cleaning, why they matter to your operations, and what the future might hold for this emerging technology.

Why Hull Cleaning is Mission-Critical

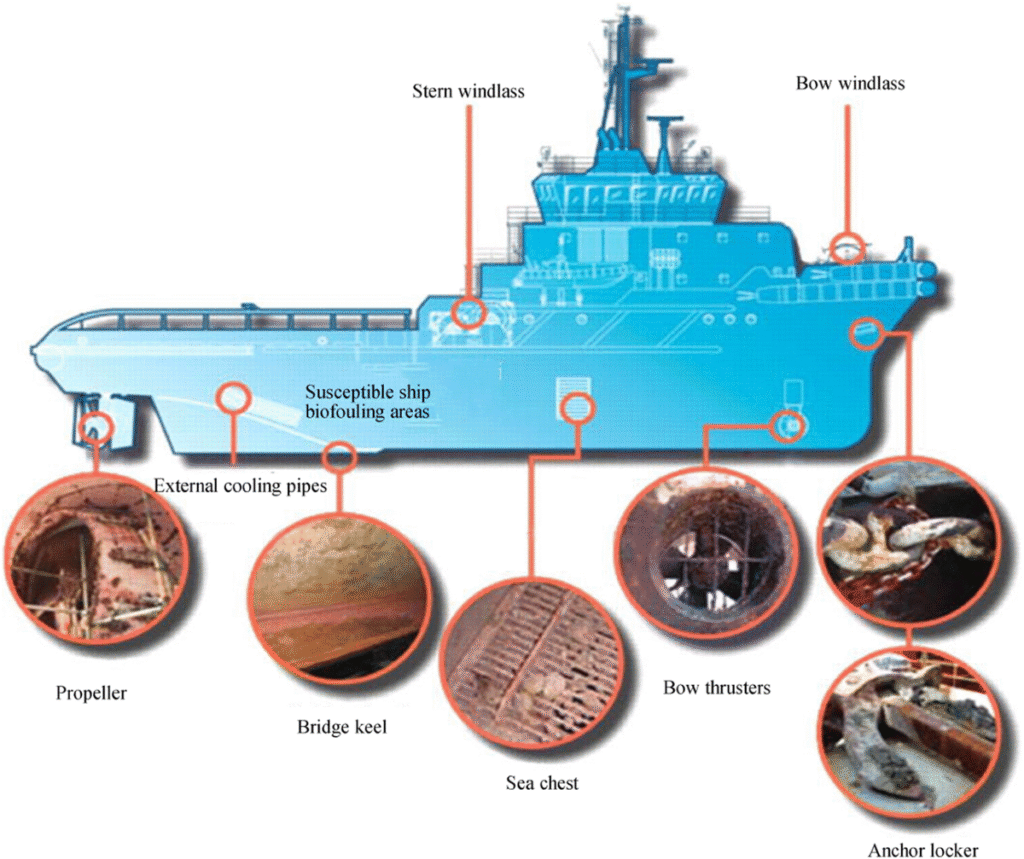

Hull cleaning is far more than cosmetic maintenance. When marine organisms like algae, barnacles, and mussels settle on a ship’s hull, they cause biofouling. This buildup increases hull roughness and friction, forcing engines to burn more fuel to maintain speed. According to the International Maritime Organization (IMO), heavy biofouling can increase fuel consumption by up to 40%. That’s not just money out of pocket—it’s also extra greenhouse gas emissions.

Think of biofouling as cholesterol in arteries. Just as clogged arteries make it harder for blood to flow, a fouled hull makes it harder for a ship to move smoothly through water. Cleaning is like preventive medicine, ensuring peak health and efficiency of the vessel.

The Traditional Hull Cleaning Challenge

Historically, hull cleaning has been done by human divers. Armed with brushes and scrapers, divers remove biofouling manually, often in risky and time-consuming operations. While effective, this method comes with several critical downsides:

- Safety Risks: Divers face dangers of entanglement, decompression sickness, and reduced visibility.

- Environmental Concerns: Scrubbing can release invasive species into new waters, violating the MARPOL Convention on marine pollution.

- Costly Downtime: Manual cleaning often requires vessels to pause operations, cutting into profitability.

- Limited Precision: Human divers may miss spots or apply uneven cleaning force, leaving residual growth behind.

This is where Magnetic Crawler Robots step in to flip the script.

Enter Magnetic Crawler Robots

Picture a compact robotic system equipped with powerful magnetic tracks that cling to the steel exterior of ship hulls like a barnacle—but one that cleans rather than clings. These robots maneuver with precision, sometimes even under zero visibility conditions, guided by built-in cameras and sensors.

Magnetic Crawler Robots are equipped with:

- Magnetic adhesion systems enable a strong grip on hull surfaces.

- High-pressure water jets or brushes to dislodge biofouling.

- Cameras and sensors for real-time navigation and monitoring.

- Data logging systems to provide detailed inspection reports.

The result? A smarter, safer, and more environmentally compliant approach to hull cleaning.

At Marine Super Cargo, we provide trusted marine cleaning solutions across 1,100+ ports worldwide. From hold cleaning to underwater hull cleaning and tank cleaning, our services are designed to keep your fleet fully compliant, efficient, and cargo-ready. pic.twitter.com/N5VYZZjlQH

— Marine Super Cargo (@Marinsupercargo) September 11, 2025

Key Benefits of Magnetic Crawler Robots

1. Enhanced Safety

No more sending divers into risky underwater environments. By deploying Magnetic Crawler Robots, operators protect human lives while still achieving comprehensive hull cleaning.

2. Better Compliance

Authorities like the International Council on Marine Industry Associations (ICOMIA) and IMO encourage techniques that prevent invasive species transfer. Since robots can capture and safely dispose of biofouling residues, they make compliance with MARPOL and IAPH guidelines easier.

3. Cost-Efficient Operations

Cleaner hulls mean smoother sailing. Reduced drag leads to up to 10–20% savings in fuel consumption. Considering bunker fuel is one of the biggest cost drivers for ship operators, the payback is substantial.

4. Minimal Downtime

Unlike manual diving crews, Magnetic Crawler Robots can work while ships are alongside in port for cargo operations, slashing downtime significantly.

5. Optimized Performance Tracking

With built-in sensors, robots don’t just clean—they inspect. Operators get detailed hull condition reports, helping with preventative maintenance and coating management. Read more

Real-World Applications Today

Shipping companies across the globe are already trialing Magnetic Crawler Robots. For instance:

- Energy Majors: Oil tanker fleets use robotic hull cleaners to improve compliance with ballast water and invasive species rules.

- Container Operators: By deploying robots during cargo turnovers in ports, ship managers optimize turnaround times and reduce delays.

- Naval Forces: Military vessels require peak performance in stealth and maneuverability. Robots provide non-intrusive yet effective hull maintenance.

The versatility of these machines means they are not limited to oceangoing ships. Offshore platforms, FPSOs (Floating Production Storage and Offloading units), and even port infrastructure benefit from robotic cleaning solutions.

Magnetic Innovation: How They Work

A simple analogy helps here. Imagine a robotic vacuum cleaner that clings to walls using magnets rather than riding on the floor. Replace dust with barnacles, and you’ve got a good idea of how Magnetic Crawler Robots operate.

- Magnetism: They generate a strong magnetic field to hold tight against currents.

- Propulsion: Robotic tracks or wheels drive them across the hull surface.

- Cleaning Action: High-pressure waterjets or rotating brushes remove fouling.

- Data Capture: Cameras record live visuals, while sensors detect coating thickness or corrosion.

This technology transforms the cleaning process from a blind, manual effort to a precise, science-driven operation. Read more

Environmental Impact: A Cleaner Future

One of the strongest cases for Magnetic Crawler Robots lies in sustainability. Traditional hull cleaning methods can inadvertently release large volumes of biofouling into local ecosystems. For example, barnacle larvae from one ocean can infest waters halfway across the globe if released during cleaning.

Robotic systems, however, can integrate collection units that trap residues for proper disposal ashore, aligning with IMO guidelines on biofouling management and helping reduce risks of invasive species. By supporting cleaner seas, they strengthen the shipping industry’s reputation in environmental stewardship.

Challenges and Limitations

While the future looks bright, no solution is perfect. Magnetic Crawler Robots face challenges such as:

- Initial Investment: Costs may be high for smaller ship operators.

- Magnetic Limitations: Robots work best on steel hulls but may struggle on aluminum or composite-coated surfaces.

- Operational Complexity: Systems may need crew training for deployment and maintenance.

Yet ongoing research, driven by organizations like IMCA and research institutes, promises to make robots cheaper, more adaptable, and smarter with AI-driven navigation.

Future of Magnetic Crawler Robots

Looking ahead, we may see AI-guided robots capable of fully autonomous operations. Imagine a fleet where each ship deploys its magnetic crawler monthly without human oversight. Machine learning could allow robots to predict fouling patterns, optimizing cleaning schedules before performance dips. Learn more

Integration with drones or automated port cleaning stations could expand the horizon even further. Just as drones revolutionized aviation inspections, robots are poised to redefine hull cleaning standards.

Conclusion

As we’ve seen, Magnetic Crawler Robots are more than just machines. They represent a leap forward in hull cleaning technology—safer for humans, better for the environment, and cheaper for ship operators.

3 Key Takeaways:

- Robots reduce risk by eliminating the need for divers in hazardous waters.

- They help shipowners comply with IMO and MARPOL biofouling regulations.

- They deliver real cost efficiency through fuel savings and performance optimization.

The shipping industry stands at the cusp of a robotic revolution. To explore practical, sustainable solutions for your fleet, we recommend visiting CleanShip.co, a trusted source for insights into eco-friendly hull cleaning innovations.

FAQs:

Q1. What are Magnetic Crawler Robots used for in shipping?

They are used for underwater hull cleaning, inspection, and maintenance, helping reduce fuel consumption and ensure compliance with IMO regulations.

Q2. How do Magnetic Crawler Robots stick to ship hulls?

They use strong magnetic adhesion systems that let them cling firmly to steel hulls, even under water currents or rough sea conditions.

Q3. Are Magnetic Crawler Robots environmentally friendly?

Yes. They can trap and capture biofouling instead of releasing it into local waters, making them more compliant with MARPOL and IAPH standards.

Q4. Do Magnetic Crawler Robots work on all types of vessels?

They are most effective on steel hulls, making them ideal for tankers, bulk carriers, container ships, and offshore platforms.

Q5. What is the future of Magnetic Crawler Robots in hull cleaning?

Advancements in AI and automation could soon make them fully autonomous, offering predictive hull cleaning and seamless integration with fleet management systems.