When you hear the word “cavitation,” it might sound like an abstract technical problem. In reality, for ship operators, it can be the silent storm eating away at rudders. Cavitation forms when bubbles collapse violently on the rudder’s surface, causing pitting, cracks, and structural wear. Pair this with fouling, and the problem grows worse. That’s why rudder cleaning cavitation prevention is no longer just optional—it’s a critical step in protecting efficiency, lowering costs, and avoiding compliance risks.

In this article, we’ll explore the real costs of cavitation damage, how rudder cleaning plays a vital role in prevention, success stories from fleets worldwide, and future innovations shaping the way you manage rudder health.

Why Rudder Cleaning Cavitation Prevention Matters

The rudder is more than a steering device—it’s the ship’s underwater compass. A fouled or corroded rudder disrupts flow, making cavitation more severe and costly.

Here’s why tackling cavitation with cleaning matters:

- Prevents structural damage: Cleaning removes marine fouling, reducing turbulence and bubble collapse intensity.

- Boosts energy efficiency: A clean rudder streamlines water flow, easing strain on engines.

- Reduces repair bills: Cavitation erosion demands expensive dry-docking if not managed.

- Supports compliance: Efficiency links directly to IMO and MARPOL emission goals.

Neglecting rudder cleaning cavitation prevention is like driving with bald tires—ignoring the problem only makes the breakdown inevitable.

The Science of Cavitation

Cavitation occurs when pressure around rudder surfaces drops, forming vapor bubbles that collapse with force. This collapse releases energy strong enough to pit steel.

- Initiation: Poor surface conditions or fouling increase irregular flows.

- Bubble collapse: Creates micro-jets that strike rudder metal at high velocity.

- Long-term effect: Pitting, fractures, and complete coating failure.

When paired with biofouling, cavitation accelerates, leaving rudders exposed to rust and corrosion faster than anticipated.

Rudder Cleaning Cavitation: The Hidden Costs

For many operators, cavitation isn’t detected until it’s already expensive.

- Fuel inefficiency: A damaged rudder increases drag.

- Dry-dock repairs: Cavitation pitting often requires welding, recoating, or even partial rudder replacement, costing millions.

- Downtime losses: Extended ship unavailability impacts charter commitments.

- Legal exposure: Non-compliance with IMO energy efficiency mandates can result in detentions.

Preventive cleaning is far cheaper than post-damage repairs. Also read about Underwater hull cleaning in France.

How Rudder Cleaning Prevents Cavitation

- Biofouling removal: Keeping rudder surfaces smooth reduces turbulent flow patterns that trigger cavitation.

- Inspection opportunities: Cleaning exposes early pitting signs before they worsen.

- Preservation of coatings: Proper techniques prevent peeling, maintaining protective layers.

- Flow restoration: A smooth rudder guides water more effectively, reducing pressure imbalances.

By integrating scheduled cleanings into maintenance cycles, operators extend rudder life for decades.

Case Studies: Prevention That Paid Off

Case Study 1: Bulk Carrier in Asia

Routine underwater inspections revealed early signs of pitting. After implementing quarterly rudder cleaning cavitation programs, cavitation slowed, saving an estimated $700,000 in repair costs over three years.

Case Study 2: Tanker in Europe

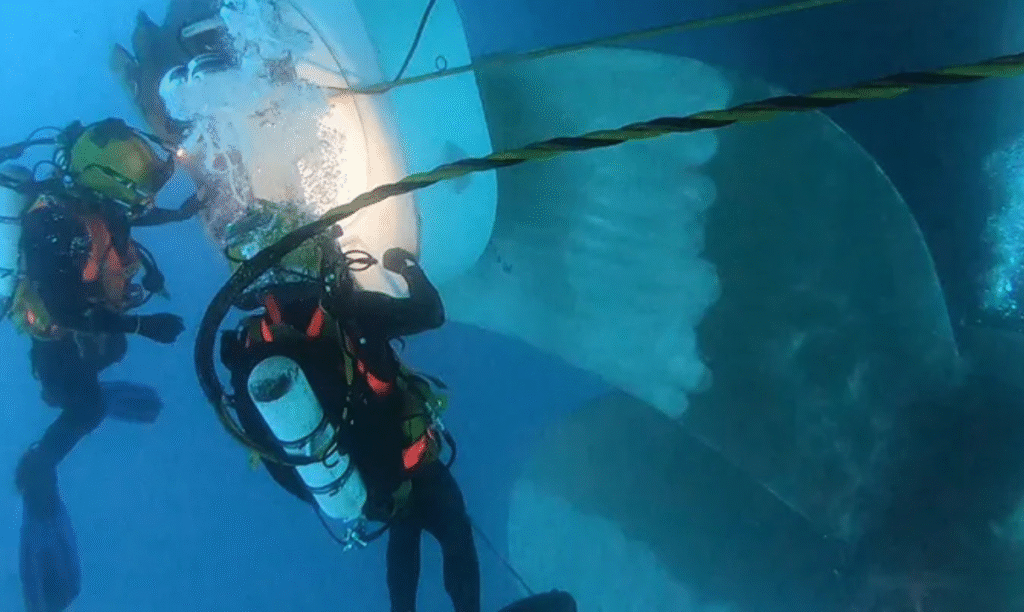

Biofouling was cleared through robotic cleaning, reducing cavitation erosion. Post-cleaning fuel efficiency improved by 3%, while emissions fell in line with MARPOL Annex VI targets.

Case Study 3: Offshore Fleet in South America

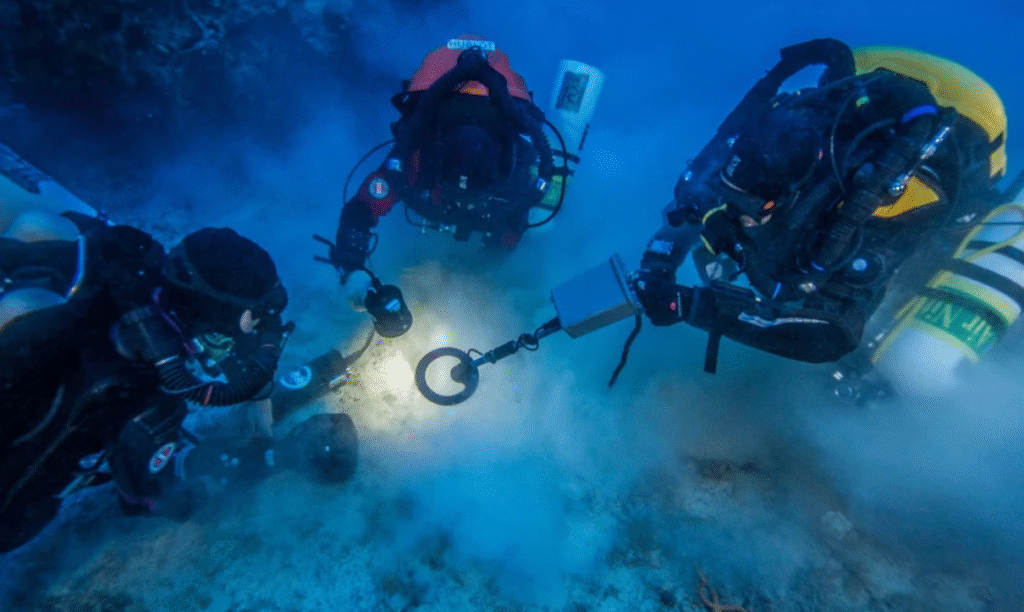

ROV-assisted cleaning eliminated diver risks while addressing rudder cavitation. Documented improvements supported compliance audits and ESG reporting.

✅ 4 Things to Check for Safety at Sea pic.twitter.com/dAxhJQ2i6U

— Marine Super Cargo (@Marinsupercargo) September 14, 2025

Industry Standards and Compliance

Ship owners can’t overlook the compliance angle:

- IMO: Ties propulsion system efficiency directly to decarbonization targets.

- MARPOL Convention: Considers fuel waste linked to rudder inefficiencies as preventable emissions.

- IMCA: Establishes diver safety protocols, encouraging robotic cleaning solutions.

- IAPH: Sustainability initiatives call for proactive anti-cavitation maintenance.

Rudder cleaning cavitation management is as much about preventing fines as it is about saving fuel.

Best Practices for Rudder Cleaning Cavitation Prevention

- Schedule cleanings quarterly to limit fouling accumulation.

- Use trained crews or robots to prevent coating damage.

- Document all cleanings for compliance audits and charter negotiations.

- Combine cleaning with propeller maintenance for complete flow efficiency.

- Embrace eco-friendly practices to meet port sustainability goals.

Future of Cavitation Prevention

Technology offers new answers to an old problem:

- Smart coatings that resist both fouling and cavitation.

- AI monitoring systems are predicting cavitation zones on rudders.

- Advanced robotics that both clean and scan for damage indicators.

- Digital twins modeling pressure flows to design better rudder surfaces.

The shipping industry is shifting from reactive repair to predictive, preventive maintenance.

Business Case: Why Owners Should Act Now

Waiting for cavitation damage to reveal itself is like gambling against physics—you always lose.

- ROI in polishing and cleaning often exceeds 10:1 when balancing repair avoidance.

- Charter appeal improves when documented cleaning reduces disputes.

- Insurance premiums ease when preventive care records reduce perceived risk.

The evidence is clear: investing in rudder condition pays both financially and reputationally.

Conclusion

Cavitation is a silent but destructive force on rudders. With consistent Rudder Cleaning Cavitation management, ship operators can secure long-term performance and safety.

The benefits are clear: Rudder Cleaning Cavitation practices deliver improved efficiency and significant fuel cost savings, while also ensuring vessels remain compliant under IMO and MARPOL frameworks. Beyond compliance, addressing Rudder Cleaning Cavitation reduces structural damage, lowers repair bills, and extends the service life of critical steering components.

By making this maintenance strategy a priority, ship owners and managers protect both their assets and their reputation in global trade.

Your rudder is too important to leave vulnerable. Safeguard it today through professional, preventive cleaning strategies. For reliable and eco-friendly solutions, visit CleanShip.co now.

FAQs:

Q1. What is cavitation, and why does it damage rudders?

Cavitation is the collapse of bubbles on a surface. On rudders, it causes intense micro-jets that pit and crack steel.

Q2. Can cleaning completely stop cavitation?

2. Can cleaning completely stop cavitation?

Not entirely, but keeping surfaces fouling-free minimizes turbulence that triggers severe cavitation damage.

Q3. How often should rudder cleaning be scheduled?

Quarterly is a strong guideline, but frequency may depend on routes, fouling rates, and operational intensity.

Q4. Are robotic cleanings more effective?

Yes. Robots ensure consistency, reduce diver risk, and often integrate cavitation monitoring tools.

Q5. How does cavitation link to compliance?

Inefficient rudders consume more fuel, raising emissions, breaking IMO and MARPOL fuel efficiency standards.