If the hull is a ship’s armor, the propeller is its beating heart. No matter how powerful your engines, if the propeller isn’t operating smoothly, performance suffers. That’s why Propeller Polishing Efficiency has become such a crucial topic in the shipping industry.

Imagine running a marathon in heavy shoes caked with mud—you’ll use more energy, cover less distance, and get frustrated fast. The same happens when marine propellers accumulate biofouling or micro-roughness.

They lose their ability to slice through water smoothly, leading to wasted energy, higher fuel consumption, and added operating costs. Regular attention to Propeller Polishing Efficiency ensures vessels regain peak hydrodynamic performance while avoiding unnecessary fuel wastage.

The good news? When done consistently, Propeller Polishing Efficiency transforms propulsion into a precision act, delivering measurable financial savings and environmental benefits. In this article, we’ll explore how polishing elevates efficiency, share real-world success stories, and examine future innovations shaping sustainable marine operations.

Why Propeller Polishing Efficiency Matters

Propellers are constantly exposed to seawater, marine growth, and cavitation forces. Over time, these factors roughen their surface, reducing hydrodynamic efficiency.

Here’s why polishing matters:

- Fuel savings: Smooth propeller blades reduce resistance, leading to 2–6% fuel savings.

- Lower emissions: Less fuel burned means lower greenhouse gases, helping with IMO decarbonization mandates.

- Reduced engine load: Cleaner propellers improve thrust, reducing stress on propulsion systems.

- Extended asset life: Preventing cavitation damage extends propeller and engine lifespan.

Propeller polishing efficiency is not a luxury; it’s a necessity in an age where compliance, cost, and sustainability intersect.

The Science of Propeller Performance

Marine engineers recognize that hydrodynamic flow around propeller blades determines efficiency. Even microscopic roughness—think of sandpaper versus glass—can generate drag.

- Unpolished propellers: Cause turbulent flow, cavitation, and reduced thrust.

- Polished propellers: Enable laminar flow, maximizing propulsion power and minimizing energy waste.

Studies show that for every 10 microns of increased roughness, ships consume significantly more fuel. By keeping surfaces polished, owners reclaim lost efficiency.

Propeller Polishing Efficiency in Practice

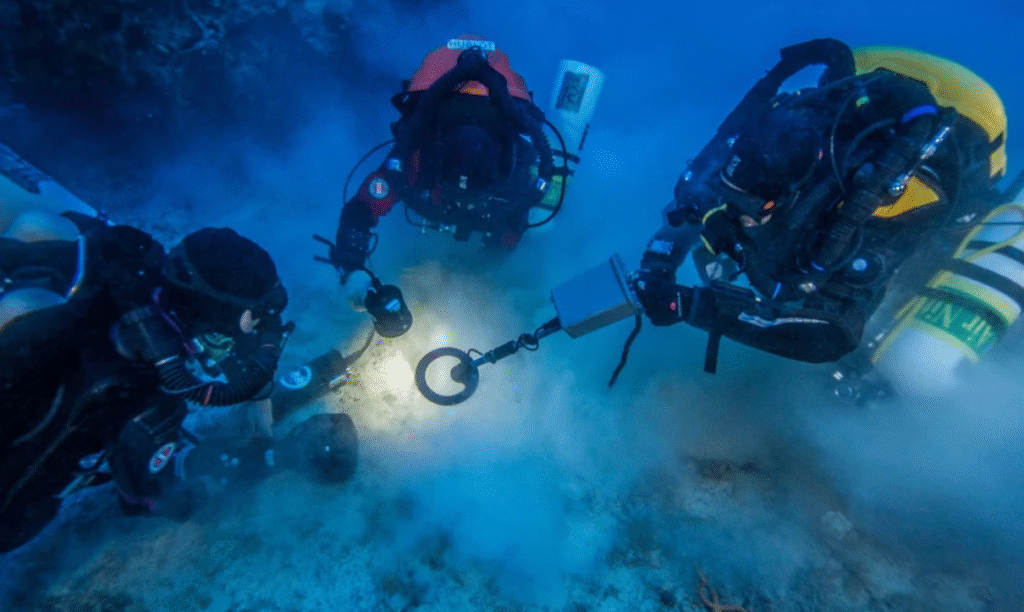

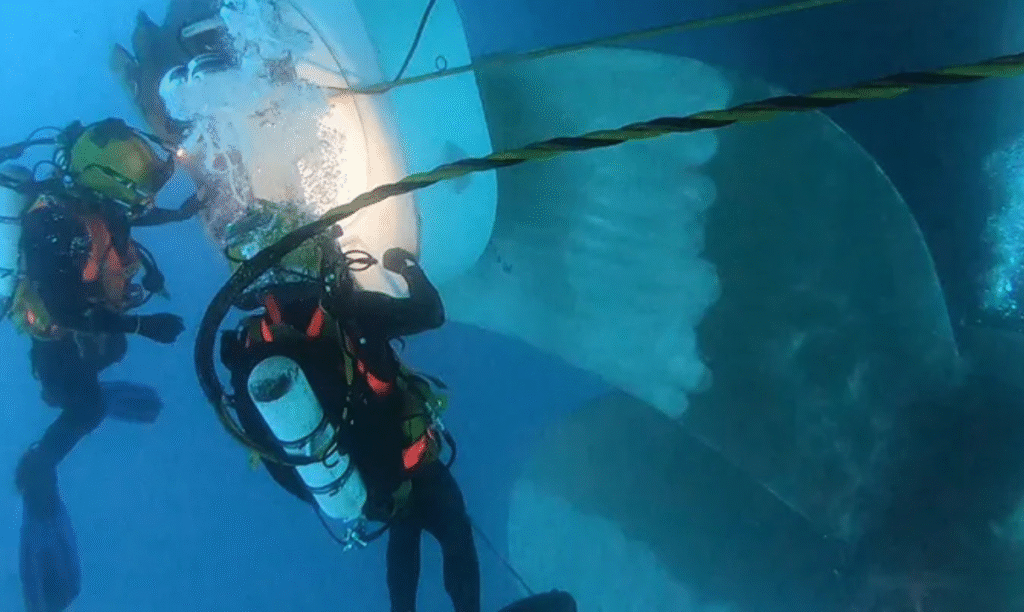

Maintenance teams apply underwater polishing tools to gently remove fouling and micro-surface irregularities. Techniques include:

- Rotary brushes: Designed for fine polishing without damaging metal.

- Diamond-embedded pads: Deliver mirror-like finishes, enhancing efficiency.

- ROV-assisted polishing: Robotics perform precision cleaning in challenging areas.

The key? Balancing frequency and precision. Over-polishing can cause material loss, while under-polishing leaves efficiency gains on the table.

Case Studies: Big Savings with Polished Propellers

Case Study 1: Container Vessel in Singapore

A vessel restored to ISO Class I propeller finish achieved a 5% reduction in fuel use, saving $450,000 annually.

Case Study 2: Tanker Operating in Europe

An operator documented a 10% cut in CO₂ emissions after consistent polishing, ensuring compliance with MARPOL Annex VI audits.

Case Study 3: Offshore Fleet in Brazil

ROV-based polishing reduced downtime for divers in offshore operations, driving a 20% increase in vessel availability.

These cases prove that propeller polishing efficiency pays dividends, not just in cost savings but in compliance reassurance. Aalso read about underwater hull cleaning in France.

Compliance Context

Propeller efficiency links directly to global maritime regulations:

- IMO: Demands lower greenhouse gas intensity through efficiency measures.

- MARPOL Convention: Sets targets for pollution prevention tied to propulsion efficiency.

- IMCA: Provides safety guidelines for underwater operations, including polishing techniques.

- IAPH: Emphasizes energy-efficient operations for global ports.

With regulators tightening emissions rules, polishing isn’t just about performance—it’s about avoiding penalties and detentions.

Environmental Impact of Polishing

Fouled, inefficient propellers force ships to waste fuel, producing excess CO₂, NOₓ, and SOₓ emissions. Polishing delivers environmental wins by:

- Reducing greenhouse gases through optimized thrust.

- Lowering energy waste, aligning with decarbonization strategies.

- Preventing cavitation damage that results in costly replacement parts.

A smoother propeller means a cleaner planet—and a stronger compliance record.

✅ 4 Things to Check for Safety at Sea pic.twitter.com/dAxhJQ2i6U

— Marine Super Cargo (@Marinsupercargo) September 14, 2025

The Business Case for Propeller Polishing Efficiency

For ship owners and managers, efficiency gains translate into long-term savings. Consider this:

- Fuel costs account for 40–60% of voyage expenses.

- A 3–5% efficiency boost may save millions annually for large fleets.

- Documented efficiency improvements help owners win charters focused on sustainability.

Neglecting polishing is like running a high-performance car with flat tires—costly, inefficient, and entirely preventable.

Best Practices for Ship Owners

- Polish frequently but wisely: Quarterly schedules often provide the best balance.

- Use certified contractors: Protect propeller integrity with proper equipment.

- Integrate monitoring: Track real-time efficiency gains linked to polishing cycles.

- Combine with hull cleaning: Maximize overall vessel performance by aligning both processes.

- Stay aligned with ESG goals: Showcase efficiency records to charterers and regulators.

Technology Driving the Future

Propeller polishing efficiency is poised for a technological leap. Innovations include:

- ROV-based polishing fleets: Automated systems that cut downtime and risk.

- Data-driven predictive maintenance: AI tracks fouling growth and polishes at the perfect moment.

- Nano-coatings: Offering super-smooth finishes that resist fouling longer.

- Digital twins: Simulate efficiency performance under varying propeller conditions.

Tomorrow’s ships will combine smart coatings with robotic polishing tools, making efficiency management seamless.

Addressing Owner-Charterer Disputes

Propeller efficiency often sparks debates between owners and charterers. Charterers may claim fuel overages stem from poor polishing schedules; owners argue environmental factors play a role.

To avoid disputes:

- Maintain transparent polishing records.

- Document efficiency metrics with before-and-after fuel consumption.

- Align expectations in charter party clauses.

Clarity reduces conflict—and proves polishing efficiency through hard data.

Conclusion

Propeller polishing efficiency transforms fleeting percentages into major wins. By focusing on polishing, operators gain:

- Lower fuel bills and reduced operating expenses.

- Stronger compliance with IMO, MARPOL, and port authority standards.

- Sustainable operations aligned with global decarbonization efforts.

A smooth propeller is more than just shiny—it’s a profit booster, a compliance tool, and a symbol of smarter maritime management. For expert support in polishing and sustainable hull care, visit CleanShip.co today.

FAQs:

Q1. How much efficiency can polishing really achieve?

Depending on fouling level, polishing restores 2–6% efficiency, sometimes higher in severely fouled propellers.

Q2. Is underwater polishing safe for propellers?

Yes. With proper techniques and certified equipment, efficiency gains are achieved without damaging blade metals.

Q3. How often should propeller polishing be done?

Quarterly schedules are typical, but frequency depends on vessel type, trade routes, and fouling exposure.

Q4. Does polishing support compliance audits?

Absolutely. Efficiency records help meet IMO carbon intensity targets and MARPOL Annex VI standards.

Q5. What future innovations can we expect?

AI-driven predictive schedules, nano-coatings, and fully autonomous robotic polishing systems.