Imagine your ship moving smoothly through the sea, its hull sleek and free from algae, barnacles, or slime. Now, picture the same vessel slowed by fouling, burning extra fuel, and increasing operational costs. Maintaining a clean hull is not optional—it’s a necessity.

Traditionally, ships relied on drydock cleaning for maintenance. However, In-Water Cleaning has emerged as a modern alternative, offering efficiency, cost savings, and reduced downtime. But how do you choose between the two methods? And what are the real-world implications for your vessel, crew, and the environment?

In this article, we’ll explore both cleaning approaches, weigh the pros and cons, examine regulatory considerations, discuss cost and environmental impacts, and highlight future innovations. By the end, you’ll have a clear understanding of which method suits your operational goals best.

What is In-Water Cleaning?

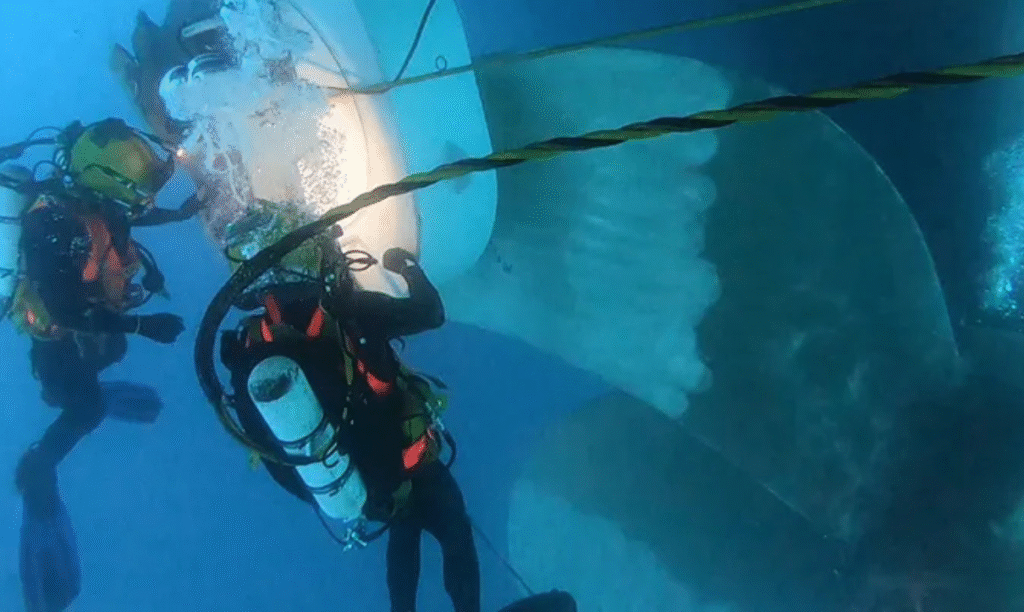

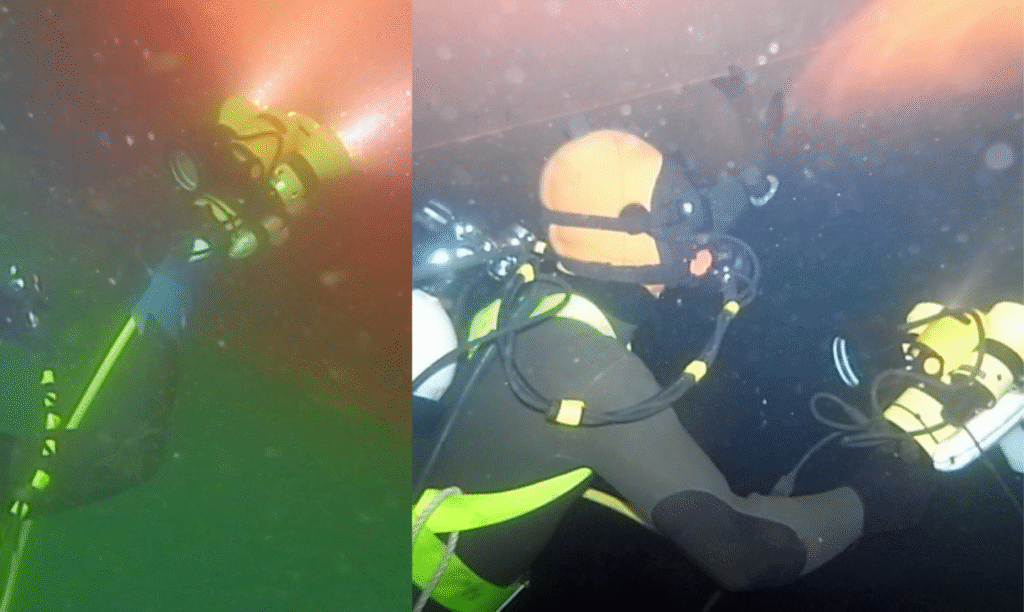

In-Water Cleaning is the process of cleaning a ship’s hull while it remains in the water. Using divers, remotely operated vehicles (ROVs), or specialized robots, marine fouling is removed without drydocking the vessel.

Key features of in-water cleaning:

- Non-invasive, performed at port or en route.

- Uses high-pressure water jets, brushes, or suction systems.

- Reduces downtime and allows for continuous hull monitoring.

Unlike drydock cleaning, which requires lifting the ship out of water, in-water cleaning integrates maintenance into normal operations, making it highly appealing to modern shipping companies.

Why Hull Cleaning Matters

Hull condition directly affects:

- Fuel Efficiency: Fouled hulls increase drag, sometimes by up to 40%, driving fuel costs higher.

- CO₂ Emissions: Extra fuel consumption increases greenhouse gas emissions.

- Regulatory Compliance: Regulations such as MARPOL limit the spread of invasive species via biofouling.

- Maintenance Costs: Clean hulls extend coating life and reduce emergency repairs.

Proper cleaning, whether in-water or drydock, ensures operational efficiency, compliance, and environmental stewardship.

✅ 4 Things to Check for Safety at Sea pic.twitter.com/dAxhJQ2i6U

— Marine Super Cargo (@Marinsupercargo) September 14, 2025

Drydock Cleaning Explained

Drydock cleaning involves taking the vessel out of water for hull inspection, maintenance, and repainting.

Advantages of Drydock Cleaning

- Comprehensive Inspection: Access to all surfaces allows for a detailed assessment of coatings and structural integrity.

- Thorough Cleaning: High-pressure water, sandblasting, or chemical methods remove all fouling.

- Repainting Opportunities: Damaged coatings can be repaired or replaced immediately.

- Regulatory Compliance: Easier to meet strict port or classification society requirements.

Limitations of Drydock Cleaning

- High Cost: Drydocking is expensive, often exceeding hundreds of thousands of dollars per vessel.

- Downtime: Taking the ship out of service for days or weeks impacts revenue.

- Environmental Risks: Chemical cleaning and paint removal can produce harmful residues.

- Logistical Constraints: Availability of drydocks is limited in certain regions.

While drydock cleaning remains the gold standard for hull maintenance, its drawbacks have spurred the adoption of in-water cleaning technologies.

Also read about underwater hull cleaning in Ghana.

Pros of In-Water Cleaning

1. Reduced Downtime

Ships can be cleaned without leaving water, meaning:

- Continuous operations

- Less schedule disruption

- Faster turnaround in ports

2. Cost Efficiency

Avoiding drydock saves:

- Docking fees

- Crew overtime

- Transportation costs to maintenance yards

Case Example: A ferry in Scandinavia used in-water cleaning every six months, saving over $200,000 annually in drydock fees.

3. Environmental Benefits

Modern in-water systems:

- Contain and filter biofouling debris

- Minimize chemical discharge

- Reduce carbon footprint through fuel savings

4. Real-Time Hull Monitoring

Divers or ROVs can detect early signs of coating wear or corrosion during cleaning, enabling proactive maintenance.

5. Flexibility

Cleaning can be scheduled according to operational needs, even at sea, avoiding port or drydock dependency.

Cons of In-Water Cleaning

1. Limited Inspection Depth

While divers and cameras are effective, some areas may be difficult to access, potentially missing minor coating damage.

2. Regulatory Restrictions

Certain ports have restrictions on in-water cleaning due to concerns about spreading invasive species or chemical residues. Always consult authorities like IMO or IAPH before proceeding.

3. Potential Coating Damage

Aggressive cleaning techniques can abrade antifouling coatings if not carefully controlled.

4. Environmental Oversight Required

Containment and filtration are essential to prevent fouling organisms and debris from entering sensitive marine ecosystems.

Despite these cons, careful planning and technology integration make in-water cleaning a highly viable solution for many vessels.

Combining In-Water Cleaning with Hull Coating Inspection

The best results often come from integrating In-Water Cleaning with inspection protocols:

- Robotic Systems: Clean while recording real-time coating conditions.

- Ultrasonic Thickness Checks: Monitor coating and steel integrity without drydocking.

- Filtration Systems: Capture dislodged fouling to prevent environmental contamination.

This approach ensures vessels remain fuel-efficient, compliant, and environmentally responsible. Leading providers like CleanShip.co specialize in these integrated solutions.

Regulatory Considerations

- IMO Guidelines: Limit chemical discharge and biofouling spread (IMO).

- MARPOL Convention: Regulates antifouling systems and pollution.

- IMCA Standards: Provide best practices for contractors and divers (IMCA).

- IAPH Recommendations: Encourage safe, standardized in-water maintenance (IAPH).

Operators must adhere to these regulations to prevent fines, protect the environment, and maintain smooth port operations.

Cost Comparison: In-Water vs. Drydock

| Factor | In-Water Cleaning | Drydock Cleaning |

|---|---|---|

| Operational Downtime | Minimal | Days to weeks |

| Direct Costs | Lower (no dock fees) | High |

| Environmental Impact | Contained debris | Potential chemical runoff |

| Inspection Capability | Moderate | Complete |

| Scheduling Flexibility | High | Low |

For vessels with tight schedules, in-water cleaning offers significant cost and time advantages.

Real-World Case Studies

Case 1: Container Ship in Singapore

- Cleaned in-water every six months.

- Fuel savings: 8% annually.

- Downtime reduced from 14 days (drydock) to 1 day.

Case 2: Regional Ferry in Europe

- Hybrid cleaning and inspection system by CleanShip.co.

- Early detection of coating wear prevented an emergency drydock.

- Environmental compliance is ensured with filtration systems.

Case 3: Offshore Support Vessel

- In-water cleaning before every port call.

- Operational efficiency was maintained without a full drydock.

- Data from sensors improved maintenance planning.

These examples show that in-water cleaning is not just convenient—it’s effective, safe, and cost-efficient.

Future Innovations in Hull Maintenance

- Autonomous Cleaning Robots: Clean and inspect hulls simultaneously.

- AI-Powered Monitoring: Predict fouling growth and optimize cleaning schedules.

- Eco-Friendly Coatings: Work seamlessly with in-water cleaning, reducing chemical use.

- Self-Healing Coatings: Minimize the need for frequent maintenance.

- Global Standards: Harmonized inspection and cleaning protocols across ports.

The combination of technology, environmental awareness, and operational efficiency points to a bright future for In-Water Cleaning.

Conclusion

Both in-water and drydock cleaning have distinct advantages. While drydock ensures comprehensive maintenance, in-water cleaning offers flexibility, cost savings, and environmental benefits without removing the ship from service.

Key Takeaways:

- In-water cleaning reduces downtime and operational costs.

- Proper inspection during cleaning ensures coating integrity and compliance.

- Technology and integrated approaches make in-water cleaning a safe, sustainable, and efficient alternative.

Partnering with experts like CleanShip.co ensures your vessel stays compliant, efficient, and eco-friendly.

FAQs:

Q1. What is In-Water Cleaning?

It’s the process of cleaning a ship’s hull while still in the water using divers, ROVs, or robotic systems.

Q2. How does in-water cleaning compare to drydock cleaning?

It saves downtime and costs, but may have limited inspection access compared to a full drydock.

Q3. Are there environmental concerns?

Yes, proper filtration and containment are required to prevent debris and fouling organisms from entering marine ecosystems.

Q4. How often should in-water cleaning be done?

Frequency depends on vessel type, operational environment, and coating type—usually every 6–12 months.

Q5. Can in-water cleaning damage coatings?

If done incorrectly or with high-pressure systems, it can abrade antifouling layers. Professional services minimize this risk.