When we talk about ships slicing through the ocean, it’s not just brute force that keeps them moving. What truly governs a vessel’s efficiency is an invisible set of rules—the hydrodynamic principles. Think of them as the “laws of flow” that determine how well a ship glides over water.

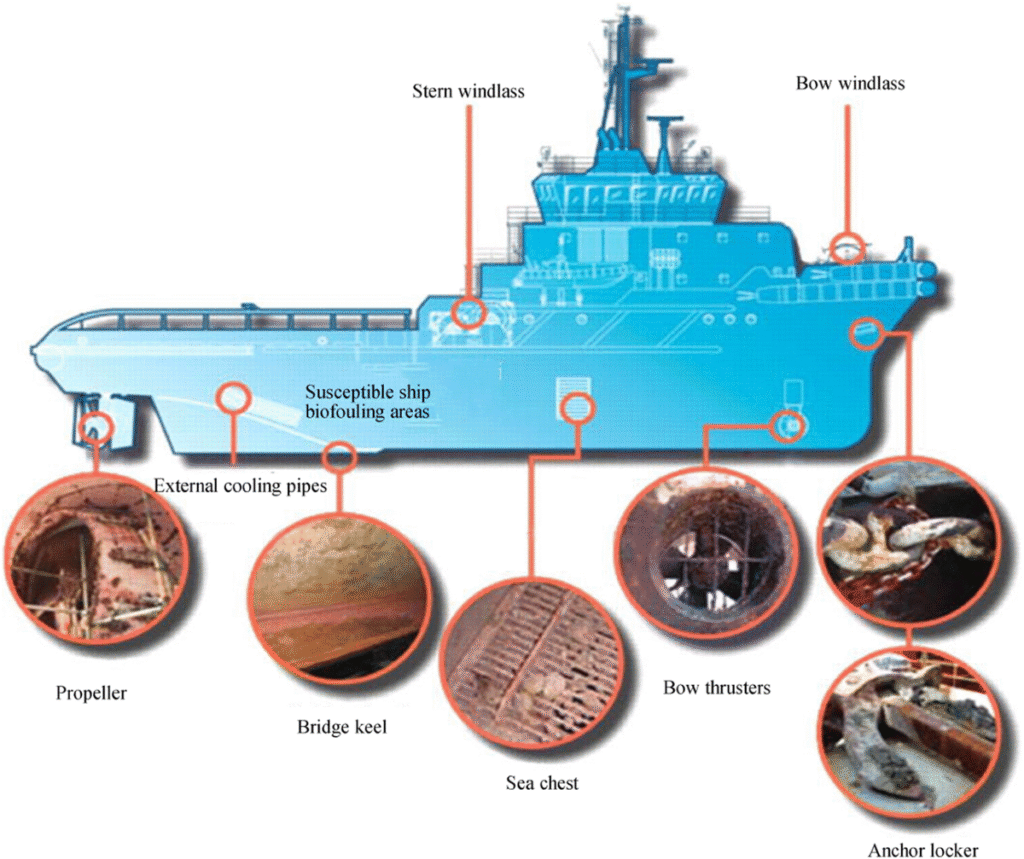

But just like a finely sharpened blade dulls with rust, these principles can be disrupted by something deceptively simple: biofouling. Sticky barnacles, slimy algae, and shell encrustations don’t just cling to the hull; they drag down speed, increase fuel use, and raise emissions.

In this article, we’ll explore hydrodynamic principles, why fouling can be a silent enemy of performance, and how ship operators can outsmart it with smart cleaning strategies.

The Invisible Science of Hydrodynamic Principles

At their core, hydrodynamic principles describe how fluids (in our case, seawater) behave when moving around solid objects. Picture dipping your hand into water. If your skin is smooth, the water slips by easily. But if you wear a rough glove, the flow becomes turbulent, and resistance increases. Ships face the same challenge.

Here are the key hydrodynamic principles at play when a vessel moves:

- Drag and Resistance: Water resists hull movement. The smoother the hull, the lower the drag.

- Laminar vs. Turbulent Flow: Ideally, water wants to stay in smooth laminar sheets along the hull. Fouling pushes it into turbulence, creating chaotic eddies and wasted energy.

- Boundary Layer: A thin zone of water touches the hull, influencing drag. Fouling thickens this boundary, raising friction dramatically.

- Wave Formation: The faster the hull, the larger the wave systems it generates. A fouled surface amplifies these losses.

- Viscous Effects: As water clings to biofouled sections, extra resistance is created, much like cycling against the wind.

Together, these hydrodynamic principles explain why even a thin microbial film can impact global shipping performance.

When Fouling Hijacks Hydrodynamic Principles

Marine fouling is nature’s graffiti. From tiny diatoms to mussel colonies, these organisms accumulate on hulls. The problem isn’t cosmetic. When organisms attach to a hull, they sabotage hydrodynamic principles:

- Frictional Resistance Skyrockets: Studies show that heavy biofouling can increase drag by over 80%.

- Fuel Penalties Add Up: Ships may burn 40% more fuel just to maintain scheduled speed.

- Speed Drops: Even moderate fouling can reduce cruising velocity by up to 2 knots.

- Emissions Rise: Extra fuel burned means more CO₂, NOx, and SOx emissions. This directly challenges compliance with IMO greenhouse gas reduction targets.

Imagine the hull as the skin of a racehorse. Smooth skin lets it sprint. Cover that skin with mud, and the same horse will struggle, breathing harder, burning more energy. That’s fouling’s effect on ships.

Why Hydrodynamic Principles Matter to Ship Owners

Ignoring fouling isn’t just negligence—it’s expensive. The way hydrodynamic principles interact with hull roughness directly affects:

- Fuel Bills: Up to $6 billion annually is wasted worldwide because of fouling-related drag.

- Compliance: IMO MARPOL Annex VI now monitors CO₂ intensity indices (CII). A fouled hull can lower your vessel’s rating.

- Maintenance Cycles: Ignoring fouling today means more dry-dock costs tomorrow.

- Charter Value: A fouled ship earns a reputation for inefficiency, cutting competitiveness.

For ship managers, operators, and owners, this translates to one critical takeaway: respect hydrodynamic principles, or pay the penalty.

Measuring Fouling’s Toll on Hydrodynamic Principles

How bad can a little slime really be? Let’s break it down with data:

- Microfouling (slimes and films): Adds up to 10–20% more drag.

- Macrofouling (barnacles, mussels, seaweed): Can increase drag by 50–80%.

- Fuel Efficiency Loss: A vessel with moderate fouling may consume 15–40% more fuel.

- Speed Impact: A tanker might lose 1–2 knots, making voyage planning harder.

Here, hydrodynamic principles reveal their unforgiving nature. Water movement amplifies inefficiencies—tiny biofilm layers seem harmless until they cause cascading losses.

Solutions to Align with Hydrodynamic Principles

When fouling begins to disrupt a vessel’s smooth interaction with water, restoring balance requires more than just routine maintenance—it demands a systematic approach. Ship operators must blend technology, best practices, and regulatory compliance to bring hulls back in harmony with hydrodynamic principles. Here are the most effective solutions:

1. Regular Underwater Hull Cleaning

Periodic hull cleaning is the frontline defense against drag-inducing organisms. Professional divers or remotely operated vehicles (ROVs) are deployed to scrub biofilms, barnacles, and algae before they mature into stubborn macrofouling colonies.

Proactive cleaning not only preserves hydrodynamic efficiency but also prevents excessive fuel penalties and ensures compliance with emissions regulations.

2. Advanced Hull Coatings

Modern antifouling coatings play a vital role in fouling prevention. Unlike older biocide-based paints, today’s coatings are engineered with foul-release properties, using slick, non-stick surfaces that mimic sharkskin or lotus leaves.

These coatings make it harder for microorganisms and barnacles to grip the hull, delaying fouling buildup and extending the vessel’s operational efficiency between cleanings.

3. Performance Monitoring & Data Analytics

Hydrodynamic efficiency can be continuously assessed through performance monitoring tools. By tracking indicators such as hull roughness, speed loss, fuel consumption, and propeller efficiency, operators can detect early warning signs of fouling.

Integrating AI-driven analytics helps predict fouling hotspots based on sea temperature, salinity, and trading routes—allowing for condition-based maintenance rather than reactive measures.

4. Compliance with IMO & Port Guidelines

Hull cleaning is not just about efficiency—it’s also about environmental responsibility. Poorly managed cleaning can release invasive species and toxic residues into port waters.

Adhering to IMO Biofouling Guidelines, MARPOL Annex VI, and IMCA best practices ensures that fouling removal is safe, sustainable, and compliant with international and local regulations. More ports now require proof of eco-friendly cleaning before permitting operations.

Compliance and Environmental Considerations

Beyond economics, fouling poses a dual challenge: the transfer of invasive species and increased emissions.

- IMO’s Biofouling Guidelines highlight how ships are vectors for harmful invasive species.

- MARPOL Annex VI applies pressure on fuel-based emissions.

- The IAPH (International Association of Ports and Harbors) is advocating for stricter local port water discharge rules regarding the release of hull cleaning debris.

When ships manage fouling wisely, they are not only saving costs but also contributing to global sustainability targets.

Innovations Shaping the Future

Looking forward, innovation is reshaping how we apply hydrodynamic principles to ship fouling:

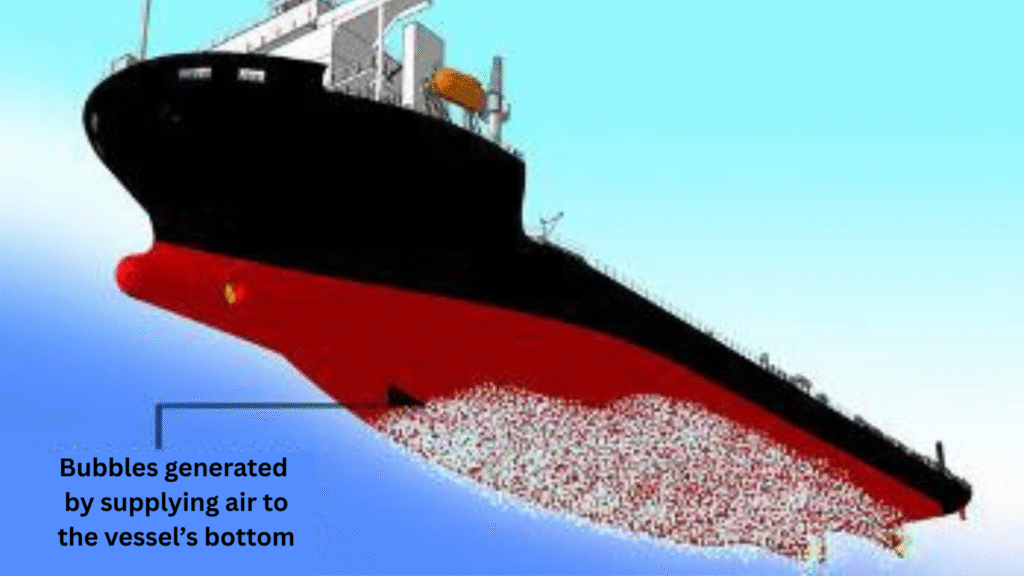

- Robotic Cleaning Drones that clean continuously, preventing biofilm from ever establishing.

- Advanced Biomimetic Coatings inspired by shark skin micro-textures.

- AI-Powered Monitoring that predicts fouling based on trading routes, sea temperature, and ship data.

- Waterless Cleaning Tools to eliminate debris discharge risks in ports.

The future ensures that hydrodynamic losses from fouling will be actively managed, not treated reactively.

Learn more about Underwater Hull Cleaning

Conclusion

Fouling is more than a “dirty hull” problem—it’s an attack on the fundamentals of efficiency. By respecting hydrodynamic principles, operators can:

- Save significant fuel costs and boost voyage profitability.

- Stay compliant with MARPOL, IMO, and port restrictions.

- Protect the environment while improving fleet performance.

The race for efficiency is here, and fouling is the invisible competitor. If you want your vessel to cut through the water like a sharpened blade, explore smarter hull-cleaning strategies with trusted guidance from CleanShip.co.

FAQ:

Q1. How do hydrodynamic principles affect ship speed?

They explain how water interacts with the hull. A clean hull maintains smoother flow and reduces drag, while fouling increases resistance and slows the ship.

Q2. Can biofouling really impact fuel consumption that much?

Yes. Even moderate fouling can increase fuel burn by 20–40%, leading to millions in extra annual costs for large shipping fleets.

Q3. What’s the difference between microfouling and macrofouling?

Microfouling involves biofilms and slime layers, while macrofouling refers to barnacles, mussels, algae, and seaweed, which drastically raise drag and fuel use.

Q4. Are there eco-friendly hull cleaning solutions?

Yes. Robotic cleaners, non-toxic antifouling paints, and port-approved underwater cleaning methods are being developed to minimize environmental harm.

Q5. Why should I care about hydrodynamic principles as a ship operator?

Because they directly decide your vessel’s efficiency, compliance rating, and operating costs. Ignoring them means higher fuel bills, lower profits, and stricter regulatory scrutiny.