A cargo vessel may glide smoothly at sea, but beneath the surface, fouling—caused by algae, barnacles, and microorganisms—gradually roughens its hull. This seemingly minor change can reduce speed by up to 10% or increase fuel consumption by 30%.

With shipping handling nearly 90% of global trade and fuel comprising over 50% of operating costs, the effects are significant. Hull roughness impacts ship speed, fuel efficiency, and maintenance cycles, making proactive management vital for cost savings and sustainable maritime operations.

Fouling Control Coatings Using Low Surface Energy, Foul Release Technology

Fouling-Control Coatings Using Low Surface Energy, Foul-Release Technology

Biofouling—the buildup of barnacles, algae, and marine organisms on a ship’s hull—directly impacts vessel speed, fuel efficiency, and operating costs. Hull roughness increases drag and resistance, forcing ships to burn more fuel and produce higher emissions.

While older antifouling paints relied on toxic biocides, today’s shipping industry is shifting to sustainable solutions. Advanced silicone-based foul-release coatings (FRCs) create ultra-smooth, hydrophobic barriers that prevent marine growth from attaching to the hull.

These eco-friendly coatings improve hull performance, extend maintenance cycles, and support compliance with IMO D-1 and D-2 biofouling management guidelines.

She is life.

— United Nations (@UN) September 2, 2025

Our future.

Our responsibility.

She is our ocean. 🌊

And though she faces growing threats, we still have the power to protect her. Our voices and choices matter.

See how you can help #SaveOurOcean: https://t.co/QtPJbVXX1N pic.twitter.com/TRwoUv03ga

Benefits of Advanced Fouling-Control Coatings

- Significant reduction in marine growth during operational periods

- Lower overall hull roughness, directly boosting speed and fuel efficiency

- Reduced maintenance downtime and longer intervals between hull cleanings

Understanding Surface Roughness

Surface roughness on a ship’s hull can serve both functional and detrimental purposes. Controlled roughness, designed during manufacturing, can improve water flow dynamics or help certain coatings adhere better. However, uncontrolled roughness caused by biofouling increases drag, slows the vessel, and raises fuel consumption.

Maintaining smooth surfaces ensures engines operate efficiently, reduces emissions, and prolongs hull coating life. Hull roughness impacts are typically measured in microns (µm) or Ra values, providing quantitative data for maintenance decisions.

How Hull Roughness Impacts Ship Speed

Resistance and Propulsion

Resistance and propulsion are inherently linked. The greater the resistance caused by hull roughness, the more thrust—and thus fuel—is required to propel the ship at the desired speed. Fouling forces engines and propellers to work harder, increasing fuel costs and accelerating wear on propulsion systems.

Benefits of a smooth hull for propulsion:

- Lower resistance: Engines consume less fuel per mile

- Fewer emissions: Reduced carbon footprint

- Sustainability: Prolonged hull coating life and less reliance on chemical treatments

Investing in fouling-control coatings and regular hull cleanings results in long-term savings, prolonged vessel life, and improved sustainability.

Hull Roughness Impacts Analyser – Working Principle

A hull roughness impact analyser measures the micro- and macro-texture of a ship’s hull to assess surface condition and fouling levels. Methods include:

- Laser or optical sensors: Emit light beams; reflected signals calculate surface irregularities

- Ultrasonic sensors: Use high-frequency sound waves; echo time and intensity reveal surface roughness

- Mechanical probes: Glide over the hull, recording height variations and texture profiles

Data is analyzed digitally, providing quantitative roughness values, trend tracking, and maintenance recommendations for optimal performance.

Condition-Based Propeller Maintenance

Condition-based maintenance monitors propeller performance and condition, scheduling servicing only when needed. Techniques include sensors, vibration analysis, and underwater inspections to detect wear, cavitation, corrosion, or fouling early.

Advantages:

- Minimizes downtime

- Reduces fuel consumption

- Extends propeller lifespan

- Maintains propulsion efficiency

- Lowers operational costs

This proactive approach ensures precise, cost-effective, and sustainable maintenance.

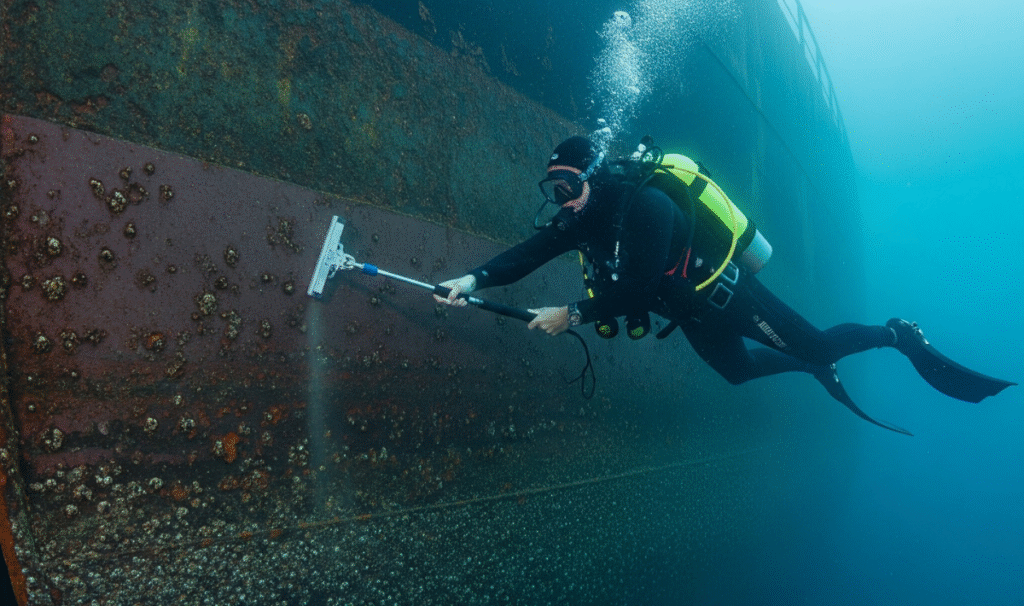

Identifying a Fouled Hull

Early detection of biofouling is critical. Signs include:

- Visible barnacles, algae, or slime

- Reduced speed or increased fuel consumption

- Discoloration or rough patches

- Diver or ROV inspections showing accumulation

- Hull roughness impacts analyser readings above normal limits

Environmental and regional factors (tropical vs temperate waters) can influence fouling rates.

Service Performance and Analysis

For modern ships, service performance measures how well a vessel maintains speed, fuel efficiency, and reliability over time. Fouling-control coatings play a crucial role, but ongoing monitoring and performance analysis complete the picture.

Key points in service performance management:

- Data tracking: Digital monitoring and in-water surveys track hull condition and fuel usage

- Analytical modeling: Algorithms predict performance impacts based on fouling data

- Continuous improvement: Real-world data informs hull cleaning schedules, coating upgrades, and operational adjustments

Underwater Hull Inspection and Fouling Assessment

Regular underwater hull inspection is essential for early fouling management. Inspection methods include:

- Diver surveys: Visual and tactile assessment of hull fouling

- ROV inspections: High-resolution video and image capture for safety and reach

- Hull roughness analyzers: Digital measurement of hull micro- and macro-texture

Hull Roughness Impacts Prevention Solutions

Preventing hull roughness impacts is crucial for fuel efficiency, operational cost reduction, and sustainable shipping. Hull roughness impacts arise from marine fouling and surface wear, increasing drag, slowing vessels, and raising fuel consumption.

Effective hull cleaning solutions reduce hull roughness impacts through proactive planning, regular underwater inspections, and high-performance, eco-friendly coatings.

Advanced monitoring and digital roughness tracking help predict and minimize hull roughness impacts, optimizing long-term vessel performance. Partnering with marine fouling prevention experts ensures IMO compliance, lowers emissions, and mitigates hull roughness impacts, maintaining peak efficiency across all trading routes.

op Service Providers

CleanShip.co

CleanShip.co is a global leader in hull cleaning, inspection, and fouling-control solutions.

Highlights:

- Comprehensive services: Inspections, non-destructive cleaning, roughness measurement, biofouling assessment, and eco-friendly coatings

- Tech strengths: Hull roughness impact analysers, AI-driven fouling prediction, tailored maintenance plans

- Proven results: Fuel savings, faster transit, reduced emissions

- Sustainability: IMO & MARPOL-compliant practices

- Customer benefits: Reliable scheduling, transparent reporting, ongoing support

Explore more at: CleanShip.co

MarineSuperCargo.com

MarineSuperCargo.com specializes in hull fouling management and operational efficiency.

Highlights:

- Underwater and drone-based hull surveys with detailed reporting

- Preventive and corrective cleaning with high-performance coatings

- Customized strategies by vessel type and trade route

- Data-driven performance tracking and benchmarking

- Proven 10–20% fuel cost savings for major fleets

Explore more at: MarineSuperCargo.com

Read Also: The Future of Underwater Hull Cleaning in Singapore Technology

Conclusion

Hull roughness significantly affects ship speed, fuel efficiency, and sustainability. Preventive actions like coatings and inspections are essential. Partnering with experts such as CleanShip.co ensures peak performance, compliance, cost savings, and operational reliability.

Maximize fuel efficiency and performance with tailored hull cleaning and inspection solutions from CleanShip.co.

FAQs:

Q1. Why is regular hull cleaning important?

Q2. How often should it be done?

Hull cleaning frequency depends on vessel routes, environmental conditions, and coating type, but most ships benefit from inspection every 6–12 months.

Q3. What are the costs involved?

Professional underwater hull cleaning can range from a few thousand to tens of thousands of dollars per service, but it typically pays for itself within months via fuel savings.

Q4. DIY vs professional hull cleaning?

DIY methods risk damaging coatings, missing biofouling areas, and violating regulations. Professionals guarantee effectiveness, compliance, and long-term hull health.

Q5. How does hull roughness impact ship speed?

Hull roughness increases drag as water flows over the vessel, forcing engines to work harder to maintain speed. Even minor fouling can reduce speed by up to 10% and increase fuel consumption by 20–30%. Maintaining a smooth hull through regular cleaning and fouling-control coatings ensures optimal propulsion efficiency, lowers operational costs, and reduces emissions, keeping the ship performing at its best.