Imagine sailing across the ocean, your ship gliding smoothly over the waves. Above the waterline, everything looks pristine, but beneath, the hull is constantly battling algae, barnacles, and other marine organisms. Even minor fouling can slow your vessel, increase fuel consumption, and impact operational efficiency.

This is where Hull Coating Inspection becomes critical. It’s not just about checking paint; it’s about ensuring that protective layers remain intact, compliant, and effective. When done during underwater cleaning, inspections provide a real-time assessment of hull health, allowing operators to take preventive action before costly damage occurs.

In this guide, we’ll explore why hull coating inspection matters, common techniques, risks, regulatory requirements, cost implications, solutions, and future innovations. By the end, you’ll understand how a thorough inspection can protect your vessel, save money, and safeguard the environment.

Why Hull Coating Inspection Matters

The hull is a ship’s first line of defense against corrosion, fouling, and chemical attack. An intact coating ensures:

- Operational Efficiency: Smooth coatings reduce drag, lowering fuel consumption.

- Regulatory Compliance: International frameworks like IMO and MARPOL require safe coating maintenance.

- Cost Savings: Detecting wear early prevents expensive repainting or dry-docking.

- Environmental Protection: Proper coatings minimize the leaching of harmful chemicals into the sea.

Without Hull Coating Inspection, you’re navigating blind, risking hidden damage that can escalate into major operational or environmental issues.

Understanding Hull Coatings

Before diving into inspections, it’s essential to understand the types of coatings typically used on ships:

1. Antifouling Paints

- Contain biocides that deter marine organisms.

- Gradually leach chemicals, requiring careful inspection to ensure compliance and effectiveness.

2. Fouling-Release Coatings

- Silicone or polymer-based surfaces that prevent organisms from sticking.

- Inspection focuses on smoothness and coverage integrity rather than chemical levels.

3. Epoxy Protective Coatings

- Provide corrosion resistance below antifouling layers.

- Critical to inspect for blistering, cracks, or delamination.

4. Self-Polishing Copolymer (SPC) Coatings

- Slowly wear to expose fresh antifouling layers.

- Inspections check for uniform erosion and coating thickness.

Each coating type interacts differently with cleaning methods, making Hull Coating Inspection vital during any maintenance operation.

Common Hull Coating Inspection Techniques

A robust inspection program uses multiple methods, depending on accessibility, equipment, and coating type.

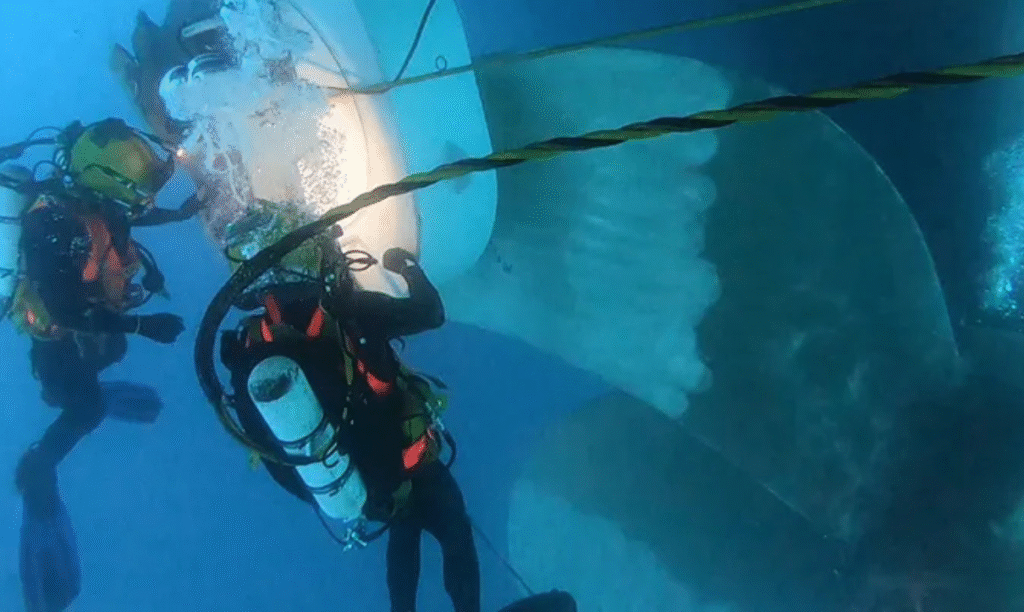

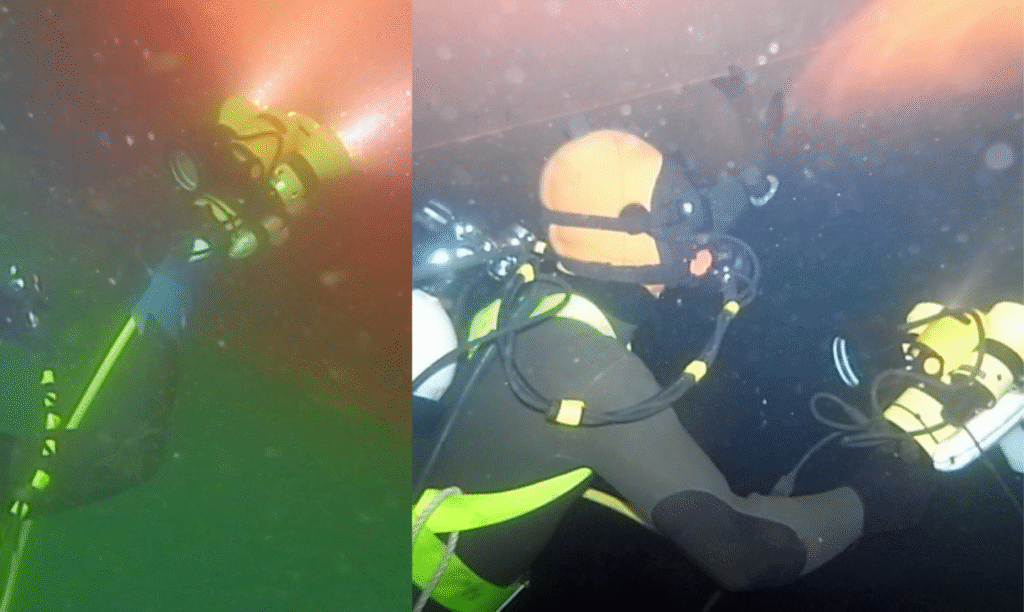

1. Diver-Assisted Visual Inspection

Divers examine the hull directly, using high-powered lights to identify:

- Blisters or bubbles

- Scratches or abrasions

- Areas of fouling accumulation

Pros: Direct assessment, flexible for various hull shapes

Cons: Time-consuming and limited by water visibility

2. Underwater Cameras and ROVs

Remotely operated vehicles (ROVs) capture high-resolution images of the hull.

- Detect cracks, corrosion spots, or coating loss.

- Useful in deep or hard-to-reach areas.

- Reduces the need for divers in hazardous conditions.

3. Ultrasonic Thickness Measurements

- Measures coating thickness and checks for corrosion underneath.

- Non-invasive and highly precise.

- Helps verify if coatings are wearing at expected rates.

4. Dye or Magnetic Particle Tests

- Specialized methods to detect micro-cracks or adhesion failures.

- Often combined with dry-dock inspections for comprehensive analysis.

A combination of these methods ensures accurate Hull Coating Inspection, helping ship owners prevent future failures.

Read also about underwater hull cleaning in Ghana.

Risks of Skipping Hull Coating Inspection

Neglecting inspection can have serious consequences:

- Corrosion and Structural Damage: Undetected coating loss exposes steel to seawater, accelerating rust.

- Increased Fuel Costs: Rough, fouled surfaces create drag, requiring more fuel to maintain speed.

- Environmental Violations: Damaged coatings may release biocides or other chemicals, breaching MARPOL rules.

- Operational Downtime: Emergency repairs or unplanned dry-docking can disrupt schedules and increase expenses.

Think of the hull as a car’s paint. If left unchecked, minor scratches worsen into rust that can compromise the entire structure. The same principle applies underwater.

Regulatory Compliance

International and regional frameworks ensure that hull coatings are maintained safely:

- IMO Guidelines: IMO emphasizes safe in-water inspection and cleaning practices to prevent pollution.

- MARPOL Convention: Regulates chemical release from coatings and antifouling systems.

- IMCA Standards: IMCA guides contractors conducting underwater inspections.

- IAPH Recommendations: IAPH encourages uniform inspection protocols across ports.

- Local Port Authority Rules: Some ports require documented inspections to permit entry or cleaning.

Following these standards protects not only the environment but also ensures uninterrupted operations and legal compliance.

✅ 4 Things to Check for Safety at Sea pic.twitter.com/dAxhJQ2i6U

— Marine Super Cargo (@Marinsupercargo) September 14, 2025

Cost Implications

Hull Coating Inspection saves money by preventing larger expenses down the line.

- Fuel Efficiency: Smooth, intact coatings reduce drag and save up to 15% fuel annually.

- Maintenance Savings: Early detection of wear avoids emergency repainting.

- Fines and Penalties: Non-compliance with IMO or MARPOL regulations can result in costly fines.

- Insurance Benefits: Documented inspections may reduce premiums by demonstrating proactive maintenance.

Case Study: A European container ship adopted an integrated ROV inspection program. They identified minor coating delamination early, preventing a full dry-dock, and saved over $250,000 in fuel and maintenance costs over a year.

Integrating Hull Coating Inspection with Underwater Cleaning

The real advantage comes when inspection is combined with cleaning operations.

- Robotic Cleaning: Advanced robots clean the hull while capturing debris and fouling for analysis.

- Visual & Digital Assessment: Inspection cameras monitor coating integrity in real-time.

- Filtration & Containment: Ensures chemical residues from cleaning don’t contaminate water.

This integrated approach maximizes efficiency, reduces environmental impact, and keeps coatings intact. CleanShip.co provides solutions combining robotic cleaning with inspection, helping operators achieve both compliance and cost savings.

Future Trends in Hull Coating Inspection

- AI & Machine Learning: Predict fouling patterns and coating wear, recommending optimal cleaning schedules.

- Smart Sensors: Embedded in coatings, alerting operators to damage before visible deterioration.

- Eco-Friendly Coatings: Inspection systems adapted for non-toxic, biocide-free paints.

- Autonomous ROVs: Self-operating robots capable of simultaneous cleaning and coating assessment.

- Global Standardization: Harmonized protocols for inspections to satisfy IMO, MARPOL, and port authorities worldwide.

The future points to proactive, technology-driven inspection that reduces downtime, extends hull life, and protects marine ecosystems.

Conclusion

Hull Coating Inspection is not just a maintenance task—it’s an investment in operational efficiency, compliance, and environmental stewardship.

Key takeaways:

- Regular inspection identifies wear early, preventing corrosion and costly repairs.

- Integration with cleaning operations maximizes efficiency and fuel savings.

- Leveraging technology, like robotics and ROVs, ensures safe, compliant, and eco-friendly maintenance.

By prioritizing inspection and working with experts like CleanShip.co, ship operators can maintain peak performance, avoid regulatory penalties, and contribute to ocean conservation.

FAQs:

Q1. What is Hull Coating Inspection?

It’s the process of assessing the condition of a ship’s protective coatings to ensure they are intact, effective, and compliant with regulations.

Q2. How often should inspections occur?

Inspection frequency varies by vessel type, coating, and operational environment, but in-water inspections are recommended at least twice a year.

Q3. Can underwater inspections replace dry-dock assessments?

They complement dry-dock inspections, providing real-time monitoring and early detection of damage without removing the ship from the water.

Q4. What technologies are used in hull coating inspections?

Common tools include divers, ROVs, high-resolution cameras, ultrasonic thickness gauges, and dye or magnetic particle tests.

Q5. How do inspections help with regulatory compliance?

Inspections ensure coatings are maintained to IMO, MARPOL, and port authority standards, preventing chemical leaching, fines, and port entry restrictions.