Picture a swimmer diving into the ocean, gliding effortlessly through the water with a slick wetsuit. Now imagine that same swimmer wearing a heavy wool sweater—drag slows them down, stamina drains, and every stroke feels like a struggle. For ships, that “sweater” is marine fouling. The solution? Fouling Release Coatings (FRCs), especially those made with silicone-based technology.

In today’s maritime world, where even a small percentage change in hull efficiency can mean millions saved in fuel, silicone-based FRCs are fast becoming indispensable. These coatings represent a leap ahead in hull protection, offering performance without relying on harmful biocides.

In this article, we’ll dive deep into what Fouling Release Coatings are, how silicone-based technology works, their benefits, compliance aspects, and the innovations steering their future.

What Are Fouling Release Coatings?

At their simplest, Fouling Release Coatings are specialized non-stick layers applied to a ship’s hull. Unlike traditional antifouling paints that use biocides to kill organisms, FRCs use slick, low-friction surfaces to prevent and release fouling organisms.

When barnacles, algae, and slime try to attach, they don’t find a hospitable surface. Instead, they cling loosely and are swept away by the water’s force once the ship is underway.

Think of it as a non-stick frying pan. Food may land on it, but it rarely sticks, and when you clean it, the residue slips away with minimal effort. That’s exactly how silicone-based FRCs work—slippery and self-cleansing.

How Silicone-Based Fouling Release Coatings Work

Silicone-based FRCs harness unique physical properties:

- Low Surface Energy

Silicone creates a slippery surface where attachment is weak. Marine organisms can’t hold on firmly. - Elastic Nature

The coatings are soft and flexible. When the hull flexes or vibration occurs, attached fouling is dislodged. - Hydrodynamic Shear

As ships move at operational speeds (typically above 8 knots), water flow naturally washes away fouling organisms. - Non-Toxic Release

Unlike older antifouling systems, silicone-based FRCs don’t leach chemicals. This makes them far more environmentally responsible while still protecting hulls effectively.

This is where FRCs stand apart: rather than poisoning marine life, they make ship hulls an uninviting, temporary landing spot.

⚓ Get Your Ship Cargo Ready with Marine Super Cargo 🚢

— Marine Super Cargo (@Marinsupercargo) September 12, 2025

Your next voyage begins with a vessel that’s clean, compliant, and cargo-ready. At Marine Super Cargo, we deliver top-quality marine services: pic.twitter.com/3627aoKAZo

Why Fouling Matters to Shipping

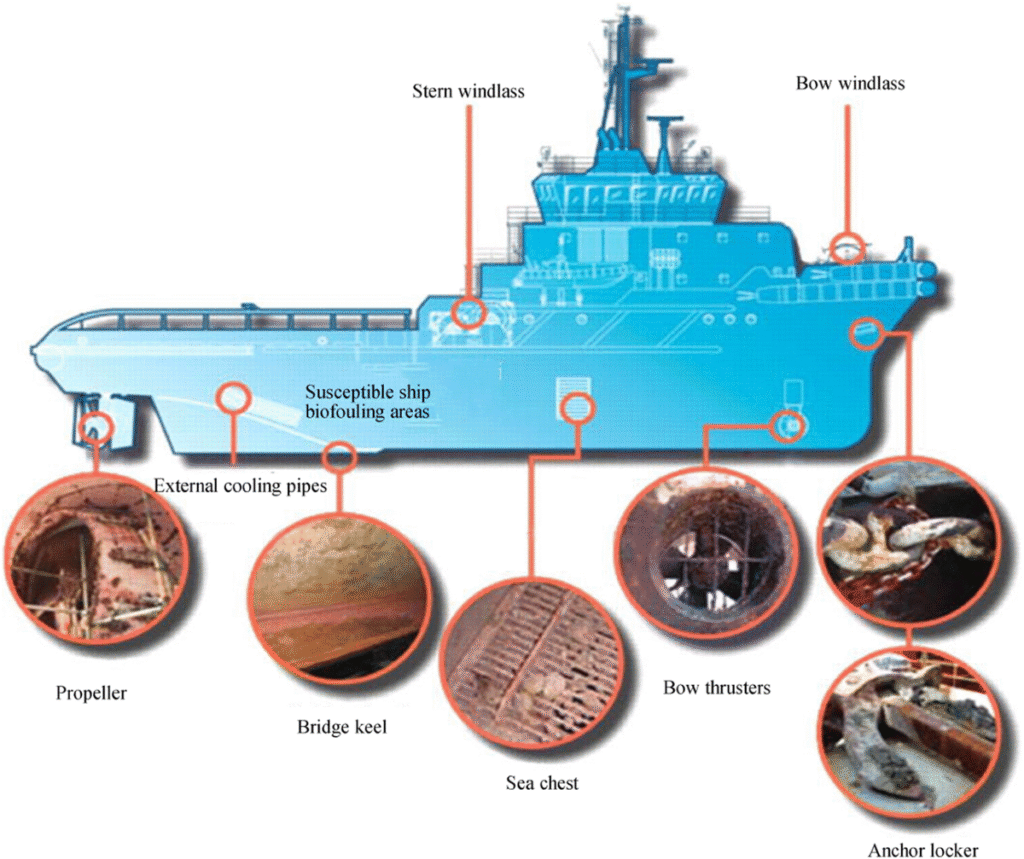

Marine fouling is more than an aesthetic problem. Without effective hull protection:

- Drag increases dramatically, raising fuel use by 15–40%.

- More emissions are produced, impacting compliance with IMO emission regulations (MARPOL Annex VI).

- Idle ships at ports risk invasive species transfer, a growing regulatory concern.

- Poorly performing hulls can lead to voyage delays and higher maintenance costs.

Clearly, clean hulls aren’t optional—they are central to commercial and regulatory success.

Benefits of Fouling Release Coatings

Let’s explore why ship owners and operators are switching to Fouling Release Coatings:

- Fuel Savings

By cutting hydrodynamic drag, FRCs can reduce fuel costs by 5–10%, translating into significant financial gains for large fleets. - Environmental Compliance

Because silicone-based FRCs are biocide-free, they comply with global environmental regulations such as the IMO’s AFS Convention. - Reduced Dry-Docking Frequency

High-performance FRCs can last more than 5 years, extending maintenance cycles and lowering operational disruptions. - Invasive Species Control

Keeping hulls cleaner reduces the likelihood of transferring invasive species, aligning with regional rules (e.g., Australia and New Zealand biofouling regulations). - Improved Speed and Efficiency

A smoother hull means less engine power is required to maintain the same speed. - Lower Greenhouse Gas Emissions

Every liter of fuel saved reduces CO₂, supporting IMO 2030 and IMO 2050 decarbonization goals. - Cost-to-Benefit Ratio

While upfront costs for silicone-based coatings are higher, the long-term operational and fuel savings often outweigh the investment.

Comparing Fouling Control Options

| Coating Type | Biocide Use | Longevity | Performance | Cost Efficiency | Eco-Friendliness |

|---|---|---|---|---|---|

| Conventional Antifouling | High | 2–3 yrs | Moderate | Low | Limited |

| Self-Polishing Coatings | Controlled | 4–5 yrs | High | High | Good |

| Fouling Release Coatings | None | 5+ yrs | Very High | Very High | Excellent |

Silicone-based FRCs are, therefore, a premium but forward-looking solution for operators aiming at long-term efficiency and sustainability.

Compliance and Regulations

Ship operators face increasing scrutiny globally. FRCs align seamlessly with these frameworks:

- IMO’s AFS Convention: Prohibits toxic biocides like organotins. FRCs are 100% compliant.

- MARPOL Annex VI: Lower drag means reduced emissions, aligning with strict limits on SOx, NOx, and CO₂.

- International Marine Contractors Association (IMCA) guidelines: Stress efficiency gains from clean hulls.

- IAPH Biofouling Initiatives: Ports worldwide are incorporating stricter fouling control requirements.

Failure to comply can lead to fines, reputational damage, or even denied port entry—an unthinkable cost for global operators.

Challenges and Considerations

While Fouling Release Coatings are highly effective, they come with considerations:

- Upfront Cost: Higher than conventional or SPC coatings.

- Application Sensitivity: Requires professional application in controlled dry-docking environments.

- Speed Dependency: Most effective on vessels sailing above moderate speeds; slow-moving or long-idle ships may need additional cleaning strategies.

Despite these, the long-term cost savings and compliance advantages often make FRCs a worthwhile investment.

Also read about underwater hull cleaning in Ecuador.

The Future of Fouling Release Coatings

Innovation is driving rapid change in this sector. Expect to see:

- Hybrid Coatings: Combining silicone-based slickness with controlled biocide release for idle ships.

- Nanostructured Surfaces: Inspired by shark skin, creating micro-patterns that repel organisms mechanically.

- Smart Coatings with Sensors: Enabling real-time fouling assessment and predictive maintenance AI.

- Greener Polymers: Enhanced formulations with sustainable raw materials.

As the industry pushes towards decarbonization and circular economy models, FRCs will take center stage in sustainable shipping strategies.

Practical Advice for Operators

If you’re planning to adopt Fouling Release Coatings, keep these tips in mind:

- Assess operational profile: High-speed, long-haul vessels benefit most.

- Time application carefully: Plan during dry-docking to maximize longevity.

- Conduct biofouling inspections regularly, as required by IMCA and regional rules.

- Monitor vessel performance digitally—track fuel use and hull smoothness.

- Partner with coating suppliers who have a proven compliance and technical support track record. Read more

Conclusion

Silicone-based Fouling Release Coatings are more than just another option on the market—they are a step forward in efficiency, compliance, and environmental responsibility.

Here are three main takeaways:

- They cut fuel use and emissions by reducing drag with a non-toxic, eco-friendly approach.

- They prolong dry-docking cycles and support global compliance standards.

- They pave the way for future-ready shipping by integrating sustainability with cost savings.

If you want your fleet to stay competitive, efficient, and regulatory-compliant, explore advanced coating solutions at CleanShip.co.

FAQ:

Q1. How long do silicone-based Fouling Release Coatings last?

They typically last 5+ years, depending on operational speeds and voyage conditions, making them longer-lasting than most traditional solutions.

Q2. Do Fouling Release Coatings require biocides?

No. They rely on surface chemistry and slickness, not toxic release, making them environmentally friendlier.

Q3. Are they effective if ships stay idle at ports?

They are less effective during long idle times since fouling can attach loosely, but usually detaches once sailing resumes.

Q4. Do they save money in the long run?

Yes. Despite higher upfront application costs, reduced fuel use and extended maintenance intervals bring a strong ROI.

Q5. Are Fouling Release Coatings suitable for all vessel types?

They are best for high-speed vessels and fleets with regular operation schedules. Slow-moving vessels may need tailored strategies.