Picture a ship slicing through calm blue waters, its hull smooth and free from barnacles, algae, or slime. Now imagine another vessel, identical in size and design, but slowed down by layers of fouling clinging to its underside. The second ship burns more fuel, emits more greenhouse gases, and spends more money—all because of what’s happening below the waterline.

This is where Eco-Friendly Antifouling Coatings come into play. These innovative solutions are designed not only to prevent marine growth but also to safeguard the ocean from toxic chemicals traditionally used in hull paints. For ship owners, operators, and managers, they represent a turning point: cleaner seas, lower costs, and full compliance with global regulations.

In this guide, we’ll explore why traditional coatings have been problematic, how eco-friendly options are advancing, and what the future holds for sustainable hull maintenance.

Why Antifouling Matters in Shipping

When we talk about ship efficiency, most minds jump to engine power, design, or fuel type. But hull condition is equally crucial. A fouled hull can increase drag by up to 40%, which means:

- Higher fuel consumption (sometimes millions in extra annual costs).

- Increased emissions contribute to climate change.

- Compliance risks are increasing as regulations tighten globally.

- Greater maintenance costs, including more frequent dry-docking.

Traditional antifouling coatings relied heavily on biocides like copper and tin. While effective against fouling, these left harmful residues in marine ecosystems. That’s why the shift to Eco-Friendly Antifouling Coatings is both a necessity and an opportunity.

The Problem with Traditional Coatings

For decades, paints containing toxic agents were the go-to solution. They worked, but at a cost.

Toxic Legacy of TBT

One of the most notorious antifouling agents was tributyltin (TBT). It was banned under the IMO International Convention on the Control of Harmful Anti-fouling Systems because it caused severe damage to marine life, from deformities in shellfish to large-scale ecological disruption.

Copper-Based Paints

Copper remains common in antifouling, but it poses risks. Excess copper leaching alters local water chemistry, harming organisms and potentially breaching MARPOL regulations.

Environmental Fallout

- Disruption of local ecosystems.

- Bioaccumulation in fish and seafood.

- Long-term sediment contamination.

Clearly, the industry needed a new path—one paved by Eco-Friendly Antifouling Coatings.

✅ 4 Things to Check for Safety at Sea pic.twitter.com/dAxhJQ2i6U

— Marine Super Cargo (@Marinsupercargo) September 14, 2025

The Rise of Eco-Friendly Antifouling Coatings

So, what makes a coating “eco-friendly”? Simply put, it prevents fouling without releasing harmful chemicals into the sea. Let’s explore the main categories.

1. Fouling-Release Coatings (Silicone-Based)

- Work by creating an ultra-smooth, non-stick surface.

- Organisms can’t attach firmly and wash away when the ship moves.

- No toxic release into the environment.

2. Biocide-Free Polymer Coatings

- Developed using advanced polymers.

- Provide physical barriers without chemical leaching.

- Durable and resistant to wear.

3. Nanotechnology-Enhanced Surfaces

- Nanostructures mimic shark skin, reducing adhesion.

- Still under development, but showing promising lab results.

4. Hybrid Coatings

- Combine silicone slickness with non-toxic additives.

- Extend lifespan and improve resistance under varying conditions.

Together, these Eco-Friendly Antifouling Coatings mark a revolution in sustainable shipping.

Technical Aspects You Should Know

To appreciate the advantages, it’s important to understand some basics.

- Surface Energy: Fouling organisms prefer rough, high-energy surfaces. Eco-friendly coatings lower surface energy, making it difficult for them to stick.

- Self-Polishing Mechanisms: Some coatings slowly wear away, exposing fresh layers without releasing toxins.

- Durability: Advanced coatings can last five years or more, reducing dry-dock frequency.

- Application Process: Most modern coatings can be applied in dry-dock using conventional spraying, with no need for major equipment changes.

By aligning these technical factors, Eco-Friendly Antifouling Coatings balance efficiency with environmental responsibility.

Compliance and Regulations

No shipping company can ignore regulations. Here’s how global frameworks push the adoption of eco-friendly solutions.

- IMO Convention on Antifouling Systems: Banned TBT and set the stage for safer coatings. (Source: IMO)

- MARPOL Convention: Focuses on preventing pollution from ships, including paint residues. (Marine Insight on MARPOL)

- IMCA Guidelines: Provide best practices for marine contractors using new coatings. (IMCA)

- IAPH Port Standards: Ports encourage or require eco-friendly hull treatments. (IAPH)

In other words, adopting Eco-Friendly Antifouling Coatings isn’t just a choice—it’s the path to compliance and global market access.

Environmental Benefits

Switching to eco-friendly coatings produces tangible benefits:

- Cleaner Oceans: No toxic chemical residues leaching into ecosystems.

- Biodiversity Protection: Reduced risk of harming local marine life.

- Invasive Species Control: By limiting fouling, these coatings reduce the spread of invasive organisms across regions.

- Climate Action: Lower drag equals reduced CO₂ emissions.

Every ship coated with Eco-Friendly Antifouling Coatings is a small but significant step toward global sustainability.

Cost-Saving Benefits for Operators

Eco-friendly doesn’t mean expensive—it means smart economics.

- Fuel Efficiency: A clean hull can cut fuel use by 10–15%.

- Reduced Dry-Docking: Longer-lasting coatings lower maintenance frequency.

- Regulatory Savings: Avoid fines for non-compliance.

- Insurance Benefits: Some insurers recognize eco-friendly practices.

Case Example: A European shipping company reported annual fuel savings of over $2 million after adopting silicone-based coatings, while also extending repaint cycles by two years.

For ship operators, Eco-Friendly Antifouling Coatings are a win-win: they cut costs while meeting environmental obligations.

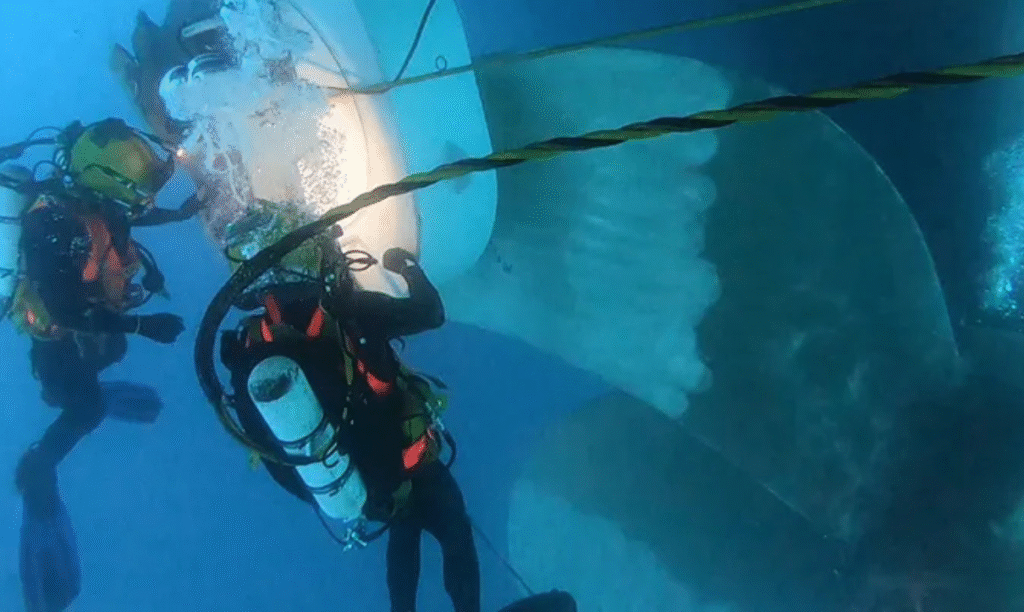

Read also about underwater hull cleaning in Ghana.

Real-World Case Studies

Case 1: Tanker in Singapore

A large tanker previously coated with copper antifouling faced restrictions in Singapore waters. After switching to fouling-release coatings, the vessel not only gained port access but also saved 12% on fuel annually.

Case 2: Ferry in Scandinavia

A regional ferry operator applied biocide-free polymer coatings. They reported smoother docking operations, cleaner hull inspections, and zero environmental violations.

Case 3: CleanShip.co Projects

Innovators like CleanShip.co are actively applying eco-friendly solutions worldwide. Their projects demonstrate that compliance, efficiency, and sustainability can align seamlessly.

Future of Eco-Friendly Antifouling Coatings

What lies ahead is even more exciting.

- AI-Driven Monitoring: Coatings paired with sensors to alert operators of fouling risks.

- Self-Healing Surfaces: Paint that repairs micro-damage automatically.

- Bio-Inspired Materials: Mimicking natural antifouling strategies, like lotus leaves or shark skin.

- Standardized Certifications: Expect global “green hull” labels to validate eco-friendly practices.

- Port Incentives: Discounts and faster clearances for vessels with approved coatings.

The shipping industry’s green future depends on scaling Eco-Friendly Antifouling Coatings across fleets worldwide.

Conclusion

The days of toxic antifouling are over. As regulations tighten and environmental awareness grows, the spotlight is firmly on Eco-Friendly Antifouling Coatings. They don’t just protect hulls—they protect oceans, reputations, and bottom lines.

Three key takeaways:

- Eco-friendly coatings replace harmful biocides with safe, effective alternatives.

- They offer both compliance and cost-saving benefits.

- Partners like CleanShip.co make adopting these solutions easier than ever.

The sea is our shared resource. By choosing eco-friendly options, you’re investing not only in your fleet but also in the future of our oceans.

FAQs:

Q1. What are Eco-Friendly Antifouling Coatings?

They are hull paints designed to prevent marine growth without releasing harmful toxins, using technologies like silicone slicks, polymers, or nanotech.

Q2. Are eco-friendly coatings more expensive than traditional ones?

While upfront costs can be slightly higher, they save money through fuel efficiency, reduced dry-docking, and fewer regulatory fines.

Q3. Do eco-friendly coatings last as long as conventional paints?

Yes, many last 5+ years. Some hybrid coatings even outperform traditional copper-based systems in durability and effectiveness.

Q4. How do these coatings help with compliance?

They align with IMO and MARPOL requirements and meet port-specific standards, avoiding penalties and ensuring unrestricted port access.

Q5. What’s the future of antifouling technology?

Expect innovations like AI monitoring, self-healing surfaces, and bio-inspired materials that make hull cleaning nearly obsolete.