Bitumen tank cleaning Suez remains one of the most challenging operations in the maritime industry. When vessels navigate through the strategic Suez Canal, specialized cleaning services become essential. Marine Super Cargo delivers expert bitumen tank cleaning solutions that comply with international maritime standards while ensuring operational efficiency

The viscous nature of bitumen creates unique challenges during cargo tank operations. Unlike conventional petroleum products, bitumen tank cleaning requires precise temperature control and specialized techniques. Our facility at Suez provides state-of-the-art services designed specifically for bitumen carriers transiting this critical maritime route.

Understanding Bitumen Properties and Cleaning Challenges

Bitumen’s high viscosity demands specific handling protocols. The substance solidifies at lower temperatures, adhering stubbornly to tank bulkheads, deck heads, and shell plating. Bitumen tank cleaning Suez operations must address these characteristics through controlled heating processes.

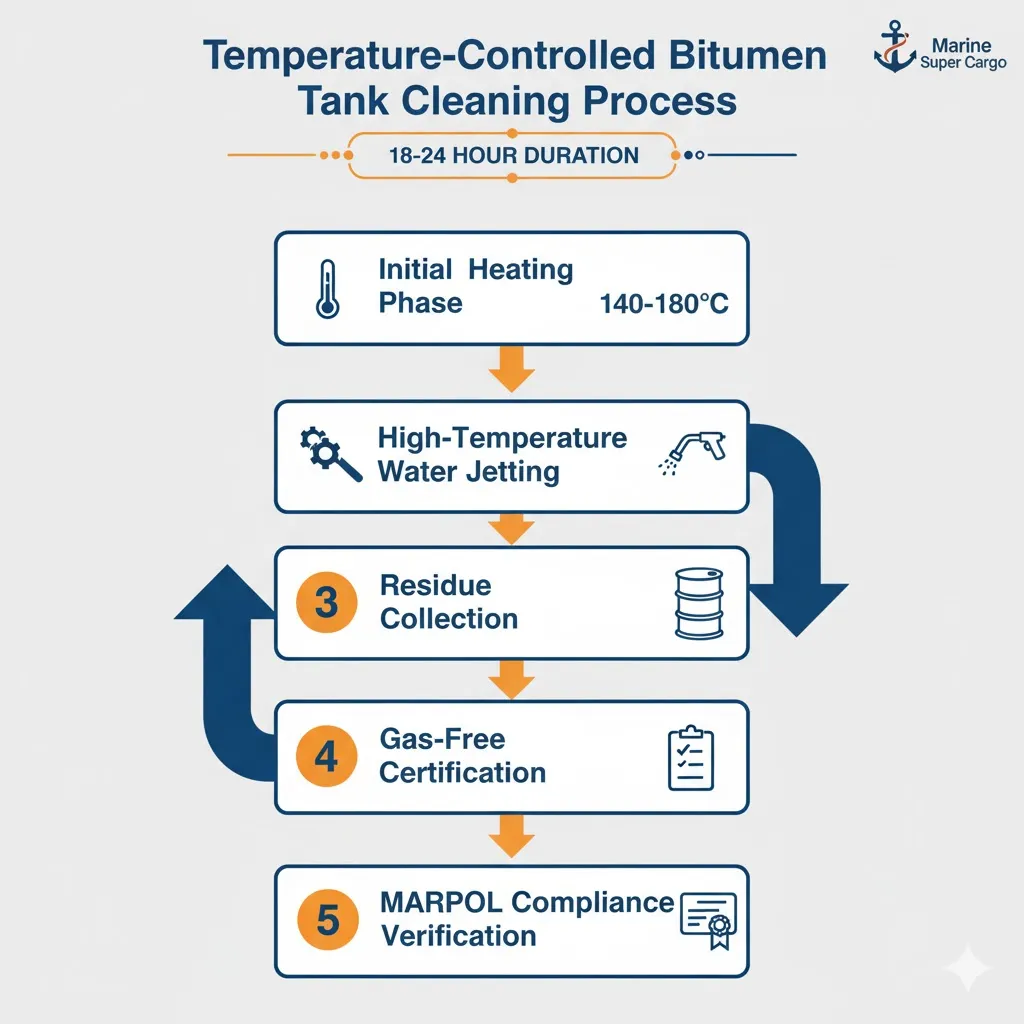

Temperature management proves critical throughout the cleaning cycle. Bitumen typically requires heating to 140-180°C for proper discharge and cleaning. Marine Super Cargo maintains specialized heating systems ensuring optimal temperatures throughout the Bitumen tank cleaning Suez process.

Temperature-Controlled Cleaning Methodology

Our Bitumen tank cleaning Suez approach begins with gradual temperature elevation. Steam heating systems warm tank surfaces systematically, preventing thermal shock to structural steel. The process follows strict protocols:

Heating coils positioned throughout the tank distribute thermal energy evenly. Our technicians monitor temperature readings at multiple points, ensuring uniform heat distribution across port and starboard sides. The forward bulkhead and aft sections receive equal attention during this critical phase.

High-temperature water jetting follows the heating phase. Specialized equipment delivers heated water at controlled pressures, removing softened bitumen residues. The process works systematically from deck head downward, allowing residues to flow naturally toward tank bottom suctions.

MARPOL and IMO Compliance Standards

Bitumen tank cleaning Suez operations must adhere to MARPOL Annex I regulations governing oil pollution prevention. The International Maritime Organization (IMO) establishes comprehensive guidelines for chemical tank cleaning operations.

Our facility maintains full compliance with MARPOL requirements. Wastewater from Bitumen tank cleaning Suez undergoes proper treatment before discharge. All residues are collected and disposed according to IMO environmental protocols.

Documentation accompanies every Bitumen tank cleaning Suez operation. Certificates verify compliance with international standards, essential for port state inspections and cargo operations worldwide.

Strategic Advantages of Suez Location

The Suez Canal’s strategic position makes it ideal for Bitumen tank cleaning Suez services. Vessels transiting between Asia and Europe can efficiently schedule cleaning operations without significant route deviation.

Marine Super Cargo operates purpose-built facilities optimized for quick turnaround. Our location reduces vessel off-hire time while ensuring thorough cleaning standards. The facility’s infrastructure supports simultaneous operations on multiple vessels.

Previous experience with chemical tank cleaning and crude oil tank washing enhances our Bitumen tank cleaning Suez capabilities. This expertise translates to efficient operations and superior results.

Safety Protocols and Environmental Protection

Bitumen tank cleaning Suez involves elevated temperatures and confined space operations. Our safety management systems address these hazards comprehensively. Continuous gas monitoring ensures safe atmospheric conditions throughout the operation.

Personal protective equipment standards exceed minimum regulatory requirements. Thermal protective clothing shields workers from heated surfaces and steam exposure. Emergency response equipment remains readily accessible at all tank openings.

Environmental protection measures prevent pollution during Bitumen tank cleaning Suez. Containment systems capture all washings and residues. No discharge occurs to surrounding waters, protecting the sensitive marine environment.

Conclusion

Professional Bitumen tank cleaning Suez requires specialized knowledge, equipment, and facility infrastructure. Marine Super Cargo delivers comprehensive services meeting the highest international standards. Our Suez location provides strategic advantages for vessels transiting this vital maritime corridor.

Temperature-controlled methods ensure effective bitumen removal while protecting tank structures. Compliance with MARPOL and IMO regulations guarantees environmental responsibility and operational legality.

Frequently Asked Questions

1. How long does bitumen tank cleaning typically require?

Complete Bitumen tank cleaning Suez generally requires 18-24 hours depending on tank size and residue thickness. This includes heating time, washing operations, and final inspection procedures.

2. What temperature range is necessary for effective bitumen removal?

Optimal Bitumen tank cleaning Suez occurs between 140-180°C. This range ensures sufficient fluidity for removal while avoiding thermal damage to tank coatings and structural components.

3. Can bitumen tanks be cleaned while vessels remain at anchorage?

Shore-based facilities provide superior results for Bitumen tank cleaning Suez. Proper heating systems, wastewater treatment, and safety infrastructure require dockside operations rather than anchorage-based cleaning.

4. What certificates are issued after completing bitumen tank cleaning?

Upon completion, Marine Super Cargo issues tank cleanliness certificates, gas-free certificates, and environmental compliance documentation meeting international maritime requirements.

5. How does temperature control prevent tank damage during cleaning?

Gradual temperature increase prevents thermal shock to steel structures. Controlled heating during Bitumen tank cleaning Suez protects tank coatings and prevents warping or stress to bulkheads and shell plating.