When it comes to ship maintenance, some of the most overlooked areas are also the ones that create the biggest headaches: bilge keels, bilge strakes, and other hard-to-reach points beneath the hull. Think of them as the hidden corners of your vessel’s body—out of sight, but never out of mind. Just as dust in the corners of a house can accumulate unnoticed until it causes problems, marine biofouling in these niche spaces quietly erodes efficiency, compliance, and safety.

In this guide, we’ll explore why these obscure parts of your ship matter more than you think, how Bilge Keels Cleaning impacts overall performance, and the strategies used by ship owners and operators to stay compliant while saving on fuel and maintenance costs.

Why Focus on Niche Hull Areas?

When most people think of hull maintenance, they picture the broad, flat bottom of the ship. While important, it’s the small, awkward corners—the niche areas—that tend to become fouling hotspots. These zones include:

- Bilge keels Cleaning– fixed fins that reduce rolling but also create sheltered surfaces easily colonized by marine growth.

- Bilge strakes – strengthened plating that runs along the lower hull, often trapping sediments and biofilms.

- Difficult access points – such as sea chests, nozzles, brackets, pipe outlets, and recesses around stern gear.

Why do these areas foul faster? They create turbulent flows, shadows, and crevices that hinder water circulation. Think of a stagnant pool—algae loves to grow where water doesn’t move. The same applies here.

The Hidden Cost of Fouled Niche Areas

Ignoring fouling in bilge keels and strakes leads to a domino effect of operational challenges. Here’s how:

- Increased fuel consumption: Hydrodynamic drag from fouling in small areas can cause significant efficiency losses. A few square meters of heavy fouling can increase fuel use by 3–5%.

- Mechanical strain: Bilge keels covered in barnacles create turbulence that stresses surrounding structures.

- Regulatory risk: IMO and MARPOL frameworks recognize niche areas as key biosecurity risks, as they transport invasive species from port to port.

- Cost escalation: Deferred cleaning often results in costly dry-dock jobs rather than quick in-water inspections approved by IMCA standards.

Bilge Keels Cleaning: Why It Matters

Bilge Keels Cleaning isn’t just a technical task; it’s the backbone of efficient hull performance. Because bilge keels extend like submerged wings from either side of the vessel, they’re prime biofouling real estate. Cleaning them ensures:

- Smoother hydrodynamics and improved energy efficiency

- Compliance with IMO’s Biofouling Management Guidelines

- Reduced risk of invasive species transfer

- Lower operating expenses over the vessel’s lifecycle

It’s like sharpening the blades of a wind turbine—you might not see it every day, but you’ll feel the difference in output.

⚓ Expert Underwater Hull Cleaning with Marine Super Cargo 🌊

— Marine Super Cargo (@Marinsupercargo) September 19, 2025

A clean hull means better performance, lower fuel use, and smoother voyages. Marine Super Cargo offers top Underwater Hull Cleaning to keep your vessel efficient, compliant, and ready for every operation. pic.twitter.com/sVKAUCytuS

Challenges in Cleaning Niche Hull Areas

Despite their importance, berth-side or in-water cleaning of bilge keels, strakes, and recesses is no easy feat. The unique challenges include:

- Accessibility: Workers and divers struggle to reach tight angles under the hull, making mechanical scrubbing complex.

- Surface design: Protruding structures like bilge keels and cleaning create shadow zones, where diver-operated brushes often miss patches of biofilm.

- Growth anchoring: Organisms like limpets and barnacles cling harder in turbulent-flow regions such as bilge strakes.

- Inspection difficulties: Unlike flat hull plating, niche areas often require specialized robotics for effective assessment.

Each of these difficulties underscores why Bilge Keels Cleaning demands more advanced planning than flat-plate cleaning alone.

Methods for Effective Bilge Keels Cleaning

To overcome these hurdles, operators are increasingly adopting specialized methods tailored to niche areas:

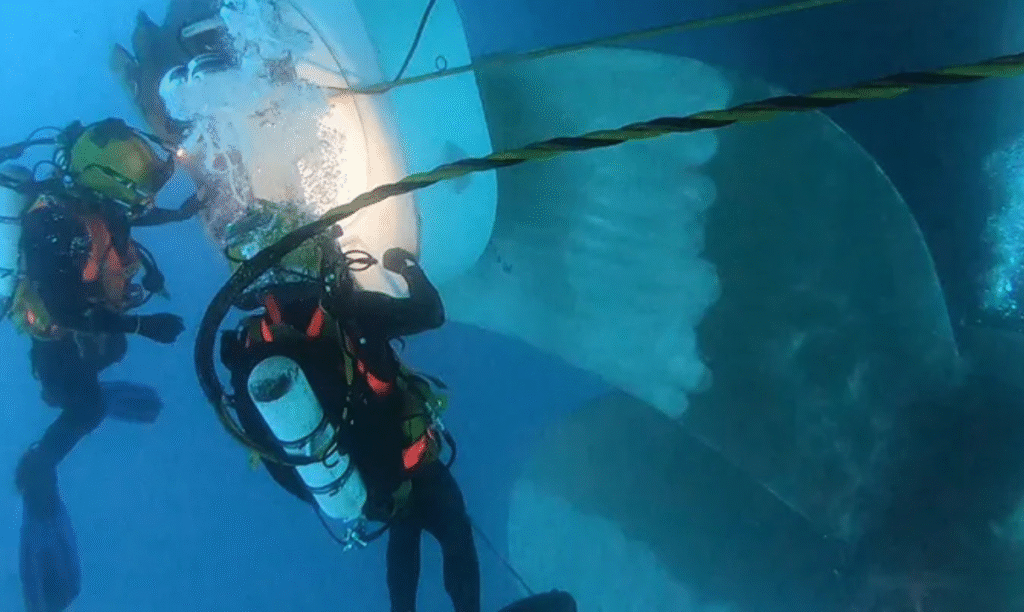

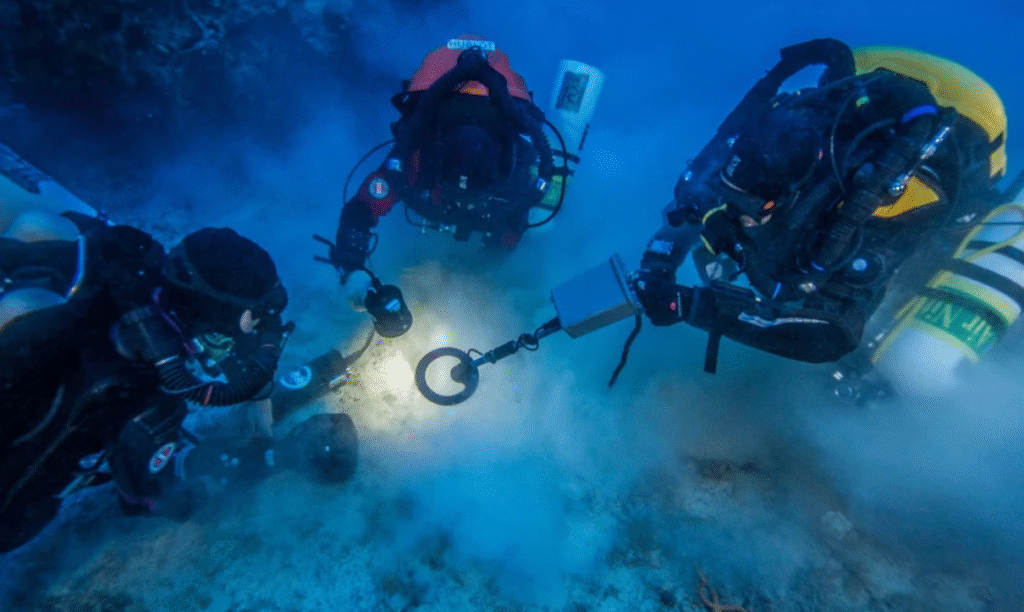

Diver-Assisted Cleaning

- Best suited for small and mid-sized vessels.

- Advantages: Precision, affordability, adaptability.

- Drawback: Risk of diver fatigue; coverage gaps in shadowed areas.

ROV-Based Systems

- Remote-operated vehicles fitted with brushes or cavitation jets.

- Advantages: Greater safety, consistent pressure, and access to difficult points.

- Drawback: Investment cost and skilled operator requirement.

Cavitation Cleaning

- Uses microbubble shockwaves to dislodge fouling without damaging coatings.

- Particularly useful in bilge strakes where mechanical brushes struggle.

Robotic Magnetic Crawlers

- Attach magnetically and self-navigate along the bilge keels cleaning.

- Provide real-time performance data for compliance records.

Compliance And Environmental Impacts

International regulations are tightening in the niche area of cleaning. Key frameworks include:

- IMO Biofouling Guidelines (2011): Stress preventive action for niche zones.

- MARPOL Annex V: Prohibits the discharge of hull cleaning debris at sea, requiring controlled disposal.

- IAPH Biofouling Ports Initiative: Encourages ports to monitor cleaning activities to avoid invasive species transfer.

- IMCA Guidance on In-Water Cleaning: Sets safety and performance standards for divers and alternative technologies.

By staying up to date with these frameworks, operators not only protect ecosystems but also safeguard reputational trust.

Innovations in Niche Area Cleaning

Future-forward fleets are already exploring technologies that promise safer, faster, and more efficient cleaning:

- AI-enabled drones that map fouling patterns in niche areas.

- Self-polishing antifouling coatings tailored to curved or recessed hull areas.

- Eco-friendly biocidal gels that can be applied only to niche problem zones instead of the entire hull.

- Digital twin modeling to simulate drag impacts of bilge fouling, aiding predictive maintenance.

These trends promise to make Bilge Keels Cleaning less reactive and more preventive. Also, read about underwater hull cleaning in Brazil.

Cost-Saving Benefits of Specialized Cleaning

Treating niche area cleaning as optional is a false economy. Here’s what you save by being proactive:

- Up to 7% reduction in fuel costs over a voyage cycle.

- Lower dry-dock intervals through consistent in-water upkeep.

- Reduced fines and inspection delays from port state authorities.

- Extended life of protective hull coatings.

Think of it like regularly flossing your teeth—an extra effort that saves you from painful dental bills later.

Operational Best Practices

To maximize returns on Bilge Keels Cleaning and niche hull care, follow these best practices:

- Schedule niche cleaning when hull roughness exceeds recommended thresholds.

- Use ROV video documentation to maintain compliance logs for inspections.

- Integrate cleaning with hull performance monitoring to track real-world fuel gains.

- Dispose of fouling waste responsibly in line with MARPOL Annex V.

- Combine antifouling coatings with scheduled in-water cleaning, not as stand-alone solutions.

Case Example: Tanker Efficiency Gains

A large tanker operating between East Asia and the Middle East faced fuel costs rising 6% above budget. Inspection reports revealed heavy barnacle fouling along the bilge strakes and growth patches around the bilge keels, requiring cleaning. Through subsea ROV-based Bilge Keels Cleaning, drag was reduced, restoring fuel efficiency. The operator reported savings of nearly $350,000 annually.

This real-world example shows that niche area cleaning translates directly into measurable financial and environmental gains. Also read about Underwater hull cleaning in Valletta

Conclusion

Focusing on niche areas like bilge keels, bilge strakes, and hidden access points is essential to ship maintenance. Bilge Keels Cleaning not only improves hydrodynamics but also safeguards compliance and reduces long-term costs. Three key takeaways stand out:

- Niche fouling carries outsized operational and regulatory risks.

- Modern technologies provide safer, more efficient cleaning options.

- Proactive cleaning yields major cost and compliance advantages.

To strengthen your fleet’s performance and stay ahead of compliance, work with expert partners like CleanShip.co, who specialize in safe, sustainable, and innovative solutions.

FAQs:

Q1. Why are bilge keels so prone to fouling?

Bilge keels create shadowed, high-turbulence areas where water circulation is poor, allowing marine organisms to attach and thrive.

Q2. How often should bilge keels cleaning be done?

Frequency depends on trading routes and water conditions, but inspections every 6–12 months are recommended to prevent heavy fouling.

Q3. Do coatings eliminate the need for niche area cleaning?

No, coatings slow biofouling but do not stop it completely. Cleaning is still essential, especially in turbulent or recessed areas.

Q4. Is in-water cleaning always allowed under MARPOL?

Not always. Some regions restrict it. Collected debris must be contained and disposed of responsibly under Annex V rules.

Q5. What future trends will make niche cleaning easier?

Expect wider use of robotics, AI-driven inspections, and specialized antifouling coatings designed for difficult hull geometries.