If the ocean is your ship’s constant companion, biofouling is its silent enemy. For decades, ship owners and operators have wrestled with barnacles, algae, and slime that cling stubbornly to hulls, raising costs and hurting efficiency. But there’s a new hero in the maritime maintenance story: robotic hull cleaning programs.

These programs aren’t just futuristic experiments; they’re real-world success stories already reshaping operations across global fleets. They promise cleaner ships, lower emissions, and stronger compliance with international standards. Think of robotic cleaning programs as the “vaccines” against biofouling—preventive solutions that make vessels stronger, faster, and more profitable.

In this detailed article, we’ll dive into compelling success stories, examine the benefits, and explore how robotic systems are rewriting the future of hull maintenance.

Why Robotic Hull Cleaning Programs Matter

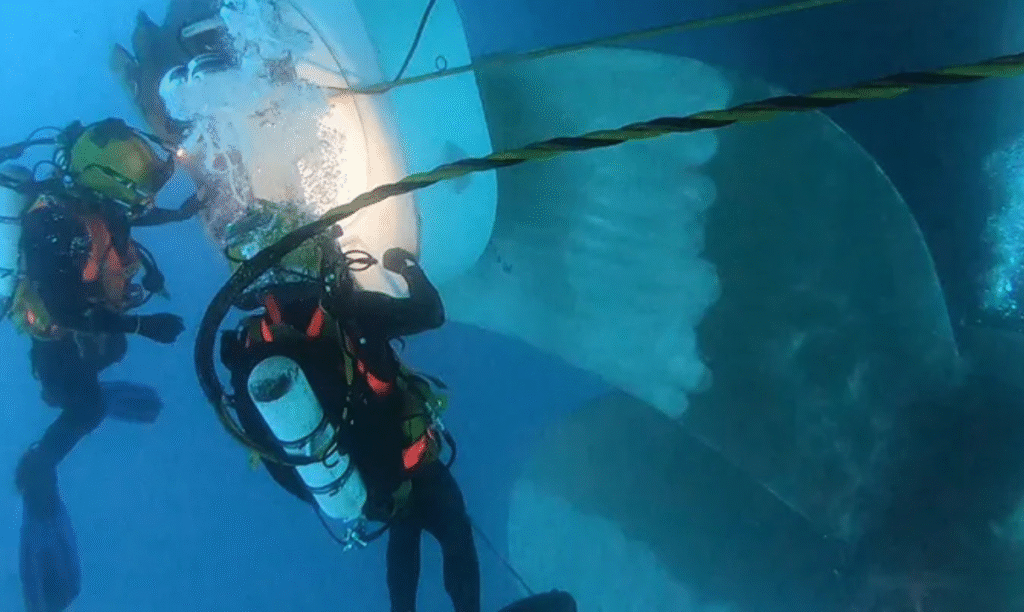

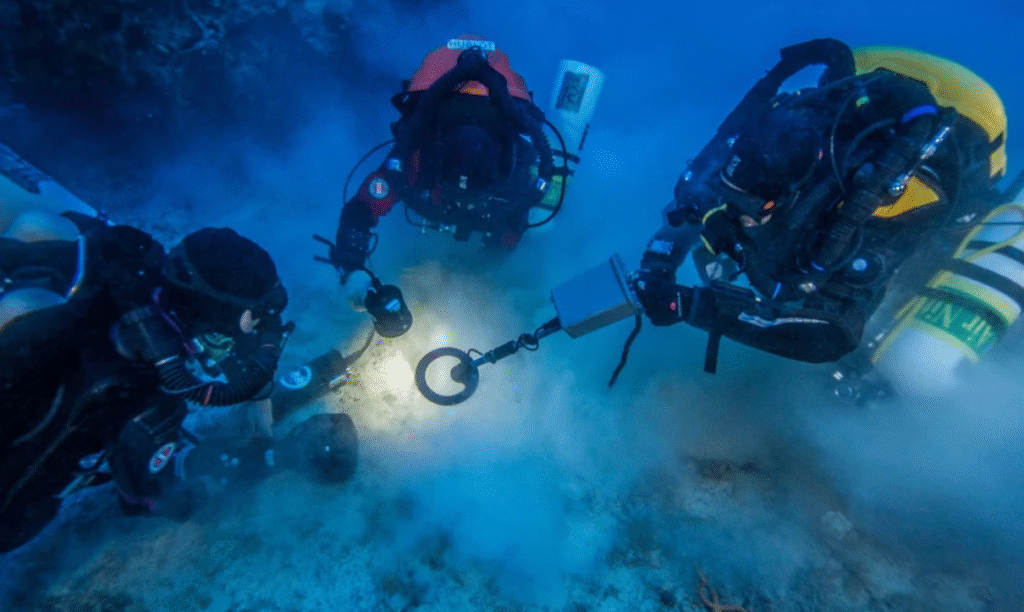

Every ship collects marine growth, no matter its age or coating. This fouling acts like an anchor of invisible weight, costing money and emissions every nautical mile traveled. Traditional cleaning methods—often manual diver teams or high-pressure scraping—invite risks ranging from coating damage to diver safety.

Robotic hull cleaning programs remove these hurdles. They replace risks with reliability, bringing:

- Consistent cleaning standards

- Reduced diver dependency and safety incidents

- Optimized cleaning schedules tied to digital monitoring

- Minimal coating damage compared to aggressive manual techniques

- Environmental protection, reducing biofouling spread per IMO guidelines

When combined with global compliance efforts like MARPOL Annex VI and IMO decarbonization targets, the value of robotic solutions becomes too sharp to ignore.

Early Success Stories of Robotic Hull Cleaning Programs

Case Study 1: Efficiency Gains in Asia

A major container operator in Singapore introduced robotic hull cleaning programs across its fleet. Within three months, it recorded a 6% fuel efficiency increase, translating into millions in cost savings per year. Diving contractors reported significantly fewer coating damages compared to traditional methods.

Case Study 2: Compliance Defender in Europe

A tanker company in Rotterdam adopted robotic cleaning under MARPOL Annex VI’s stringent emission guidelines. With robots maintaining smooth hulls, the vessel consistently passed performance audits, avoiding fines and reputational risks.

Case Study 3: Offshore Innovation in Brazil

An offshore support vessel integrated robotic hull cleaning programs into its subsea maintenance cycle. Not only did fuel costs drop, but downtime for diver-based cleanings decreased by 40%. Improved safety for crews was a bonus outcome.

Each story adds weight to the argument: robotic cleaning isn’t theoretical—it’s profitable and practical.

How Robotic Hull Cleaning Works

At its core, the process integrates technology, sustainability, and safety. Programs typically include:

- Robotic crawlers fitted with rotating brushes or water jets that clean hull surfaces without stripping paint.

- Real-time cameras and sensors capture data for inspection, coating monitoring, and reporting.

- Data logging software to track efficiency improvements and compare cleaning cycles.

- Eco-friendly waste management systems, ensuring fouling organisms are collected instead of spread into nearby waters (a growing IMO focus).

Unlike human divers, robots don’t tire, don’t risk injury, and can work with higher cleaning consistency.

The Compliance Factor

Hull fouling isn’t just about efficiency; it’s part of the compliance ecosystem. As organizations like the International Maritime Organization (IMO) tighten regulations, fouling that increases drag directly hurts decarbonization targets.

- MARPOL Convention links hull smoothness to energy efficiency design indexes (EEDI).

- IMCA sets guidelines for safe underwater operations, a key advantage of robotics protecting against diver incidents.

- IAPH encourages cleaner ships for greener port operations worldwide.

Robotic hull cleaning programs directly support these frameworks by proactively maintaining vessels within compliance brackets.

Environmental Wins

Manual cleaning often stirs fouling organisms into surrounding ports or coastal waters, creating invasive species risks. Robotic cleaning programs add containment systems that prevent marine life release, aligning with IMO’s 2020 Biofouling Guidelines, which emphasize ecological safeguards.

One operator reported that robotic cleaning reduced bio-spread by 90% compared to conventional dive cleanings. In a world where environmental indices increasingly matter to charterers and ports, that’s a competitive edge.

The Business Case for Robotic Hull Cleaning Programs

Success stories aren’t just statistics—they’re financial realities. Here’s how programs deliver measurable returns:

- Up to 10% fuel savings with smoother hulls

- Reduced dry-docking costs with fewer emergency recoating needs

- Greater operational uptime by eliminating diver delays

- Less insurance exposure thanks to reduced diver risks

- Documented compliance records for audits and port inspections

Put simply: every dollar spent on robotic cleaning can save multiples in long-term costs.

✅ 4 Things to Check for Safety at Sea pic.twitter.com/dAxhJQ2i6U

— Marine Super Cargo (@Marinsupercargo) September 14, 2025

Real Voices From the Industry

Ship owners and managers who’ve already made the switch say robotic programs deliver not only efficiency but peace of mind.

A fleet manager from Northern Europe noted: “We used to argue with charterers about hull condition—but with robotic maintenance logs, transparency speaks louder than disputes.”

Such transparency has indirectly reduced hull condition disputes, translating into smoother charter negotiations.

Future of Robotic Hull Cleaning

Technology is setting the stage for new milestones. Expect to see:

- AI-driven inspection tools predict fouling patterns.

- Autonomous cleaning fleets operating without human oversight.

- Integration with ESG dashboards, providing measurable sustainability reports.

- Smart hull coatings that “communicate” with robotic systems to signal cleaning needs.

The maritime industry is entering an era where robotic hull cleaning programs won’t just be maintenance—they’ll be part of strategic asset management.

Best Practices for Adopting Robotic Programs

Thinking of making the switch? Start here:

- Choose programs aligned with coating specifications.

- Schedule cleanings proactively, not reactively.

- Train crews to interpret robot-generated inspection data.

- Integrate cleaning reports into compliance documentation.

- Evaluate providers based on environmental performance safeguards.

Conclusion

Robotic hull cleaning programs are transforming the way fleets think about maintenance. By leveraging technology, owners and operators secure:

- Stronger compliance with IMO, MARPOL, and port authority rules.

- Substantial cost and fuel savings from smoother hull performance.

- Safer, greener vessel operations that respect both people and oceans.

For forward-thinking leaders, robotic cleaning isn’t just an upgrade—it’s the future. Explore innovative, sustainable solutions tailored for your fleet at CleanShip.co today.

FAQs:

Q1. What makes robotic hull cleaning safer than traditional diving?

Robots eliminate the need for diver intervention, reducing risks of accidents while delivering consistent cleaning quality.

Q2. How do robotic programs protect hull coatings?

Advanced tools use gentle brushes or controlled jets designed to clean fouling without stripping or damaging protective paint systems.

Q3. Are robotic cleanings accepted in compliance audits?

Yes. Audit-ready reports and inspection data from robotic programs align well with IMO and MARPOL requirements.

Q4. Is robotic hull cleaning affordable for smaller fleets?

Costs vary, but long-term savings from fuel efficiency and reduced downtime often outweigh program investments.

Q5. How often should robotic hull cleaning be done?

Frequency depends on trade routes and fouling exposure, but is typically aligned with quarterly or bi-annual cycles for best performance.