When a diver prepares to descend beneath a vessel’s hull, the operation may look simple on the surface. But behind every safe underwater cleaning task lies a structured safety framework: the Permit-to-Work System. Think of it as a captain’s log for dangerous tasks—a written agreement defining who can do what, when, and under which conditions.

In this guide, we’ll break down how the Permit-to-Work System applies to underwater cleaning, why it matters for ship owners and crew, and how adopting it reduces risks, saves money, and ensures compliance with international safety and environmental standards.

Why a Permit-to-Work System Is Crucial

The sea is both a worksite and a hazard zone. Underwater cleaning often involves divers operating around propellers, confined spaces, or potential discharge areas. Without clear systems, chaos isn’t far away. Applying a Permit-to-Work System has several key benefits:

- Prevents unauthorized or unsafe work.

- Ensures clear communication across divers, supervisors, and the ship’s crew.

- Identifies all risks and lays out safety measures in advance.

- Provides legal and documentary proof of compliance with standards like IMCA and IMO.

- Builds trust between stakeholders, knowing no corners are cut.

Imagine the permit as a boarding pass: without it, no one enters the risky “flight” of deep underwater tasks.

What Is a Permit-to-Work System?

A Permit-to-Work System is a formal, written safety control procedure that defines how high-risk jobs are executed. It is more than a piece of paper—it is an agreement that:

- Details the exact task and location.

- Specifies who is authorized to carry it out.

- Outlines risks and associated control measures.

- Provides time limits for the job’s safe completion.

- Guides emergency protocols if things go wrong.

For underwater cleaning, it is the knight’s shield—anticipating threats before divers ever touch the water.

Types of Work Covered by Permit-to-Work

In marine operations, permits are tailored to risks. Examples include:

- Hot Work Permits: When cutting, welding, or grinding near flammable materials.

- Confined Space Permits: Used when inspecting tanks or void spaces.

- Electrical Work Permits: Isolation of circuits before inspection or repairs.

- Cold Work Permits: Non-hot tasks still involving hazards, like underwater cleaning.

For ship hull maintenance, the Permit-to-Work System ensures divers and crew are aligned to control hazards ranging from entanglement to environmental spills.

Permit-to-Work System in Underwater Cleaning

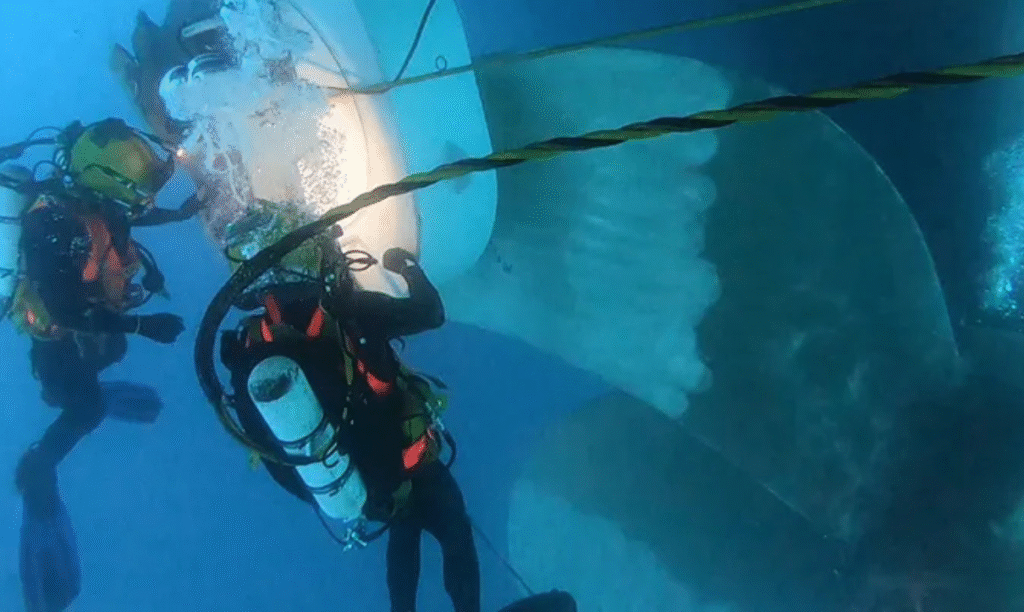

Hull cleaning may sound routine, but risk hides in every angle: divers can be struck by currents, entrapped by fouling debris, or endangered by nearby propellers. The Permit-to-Work System ensures that:

- The vessel’s engine and thrusters are confirmed shut down.

- All crew are aware that operations are underway.

- Standby rescue divers and emergency gear are in place.

- Water quality is evaluated to avoid pollution per the MARPOL Convention.

- Safe zones and time limits are defined clearly.

This transforms diving operations from “routine” into a well-coordinated safety ballet. Also, read about underwater hull cleaning in Australia.

Step-by-Step Workflow of a Permit-to-Work

Modern permits go beyond signatures. Here’s the process typically followed by compliant shipowners:

- Request & Hazard Identification

The diving supervisor files a request. Hazards such as poor visibility, biofouling entanglement, or risk of oil leaks are listed. - Risk Assessment

A structured review aligns with IMCA recommendations for risk evaluation. Each danger gets ranked by severity and likelihood. - Permit Approval & Controls

The vessel master and port safety officer review controls—such as engine lock-out, diver comms testing, or pollution booms. - Authorization

Only trained, medically cleared, and certified divers and crew are allowed by name. - Operation & Monitoring

Work begins, monitored continuously from the surface team via communications and observation. - Permit Closure

Once work is safely completed, divers debrief, hazards are logged, and the permit is officially closed out.

This system ensures accountability: every stage connects exactly the right people, resources, and decisions.

Common Hazards in Underwater Cleaning

Even routine cleaning exposes divers to risks. A Permit-to-Work System evaluates and mitigates these:

- Propeller Movement → Controlled shutdown, lock-out tags.

- Entanglement in Fouling or Nets → Cutting tools, buddy systems.

- Decompression Illness → Strict dive profiles and chamber availability.

- Pollution Discharge → MARPOL checks, capture of fouling waste.

- Poor Visibility → Task limits, lighting equipment, communication plans.

When hazards are mapped to controls in a permit, risks evolve into manageable routines.

Crew’s Role in Permit-to-Work Systems

One of the biggest strengths of the Permit-to-Work System is that it extends beyond divers:

- Shipmasters confirm vessel readiness.

- Deck crew support diver logistics and act as lookouts.

- Engineers isolate compressors, pumps, and machinery.

- Safety officers enforce compliance and track measures.

By connecting ship personnel and dive teams, the permit creates a strong operational chain that prevents accidents.

Regulatory and Compliance Framework

Maritime safety rules demand careful controls during risky tasks. The Permit-to-Work System helps fulfill obligations within:

- IMCA Guidelines for offshore diving and underwater maintenance.

- IMO safety frameworks for operations at sea.

- MARPOL Convention on safe handling of fouling debris and prevention of marine pollution.

- IAPH standards on safe port operations.

Permits show regulators a paper trail of due diligence, reducing liability risks if audits or investigations occur. Learn more.

Case Study: Permit Saves a Diver’s Life

During an underwater hull cleaning in Asia, divers prepared to clear propeller fouling. However, the Permit-to-Work System flagged that the master had not locked out auxiliary thrusters. The operation paused, corrections were enforced, and divers only resumed once isolation was verified. Hours later, strong currents surged—had the thrusters engaged, divers could have been fatally injured.

The permit stopped tragedy before it even began.

🌊✨ Client Testimonial Spotlight ✨🌊

— Marine Super Cargo (@Marinsupercargo) September 16, 2025

💬 “The team at Marine Super Cargo feels like part of our crew. From hold cleaning to supercargo support, they handle everything seamlessly. Their quick response and reliable service saved us valuable time and money.” – Mr. Ingmar Domrös pic.twitter.com/bPlooKOakt

Future of Permit-to-Work Systems

The future points toward smarter permits:

- Digital Systems: Electronic PTWs track approvals instantly across devices.

- AI Integration: Analytics identify overlooked hazards using historical data.

- Wearable Tech: Biometric trackers integrate diver vitals with the permit workflow.

- Environmental Linkage: Automatic alignment of fouling removal controls with MARPOL requirements to ensure sustainability.

With innovation, the Permit-to-Work System shifts from compliance paperwork into smart, real-time risk intelligence.

Practical Guidance for Ship Owners and Managers

- Standardize PTW checklists across vessels.

- Train crews to treat permits as mandatory, not optional.

- Include PTW audits in compliance inspections.

- Regularly review templates against updated IMCA or IMO guidance.

- Instruct divers and crew that work halts immediately if a permit lapses.

Consistency turns the permit from “bureaucracy” into a trusted safeguard.

Conclusion

The Permit-to-Work System is not just a document—it is a daily safeguard, protecting divers, crews, ships, and even the oceans. Remember these three takeaways:

- Permits directly prevent accidents and fatalities.

- Crew involvement ensures strong operational control.

- PTW supports compliance with IMCA, IMO, and MARPOL for sustainable operations.

For shipowners who value safety, compliance, and environmental responsibility, turning to experts like CleanShip.co ensures underwater cleaning runs smoothly, lawfully, and sustainably.

FAQs:

Q1. What is the purpose of a Permit-to-Work System in diving?

It controls hazardous tasks by authorization, planning, and preventive measures—ensuring divers and crew remain safe.

Q2. How does a PTW prevent underwater accidents?

It forces a structured check of risks like thrusters, entanglement, and decompression hazards, eliminating surprises mid-operation.

Q3. Who issues the Permit-to-Work on a ship?

Usually, the vessel master or authorized safety officer, in agreement with the diving supervisor and port authority.

Q4. Is a Permit-to-Work System legally required?

Yes, international conventions like IMO, IMCA guidelines, and many port authorities mandate PTWs for high-risk tasks.

Q5. Can technology improve PTW in underwater cleaning?

Definitely—digital PTWs, diver wearables, and AI hazard analytics make modern systems faster, smarter, and more reliable.