Picture this: a ship is like a marathon runner. The cleaner the shoes, the smoother and faster the performance. But if mud clings to the soles, every stride takes more effort. For ships, that “mud” is biofouling—barnacles, algae, and slime covering hulls, dragging down efficiency.

Shipping companies worldwide have battled this for decades with divers and brushes, but these old techniques come with risks, costs, and environmental concerns. Now, automation provides the answer. Enter Robotic Hull Cleaning—a breakthrough that combines efficiency, safety, and sustainability. Two standout systems leading this charge are HullWiper and Groom.

In this article, we’ll explore how Robotic Hull Cleaning is transforming hull maintenance, why HullWiper and Groom are game-changers, and what the future looks like for this technology.

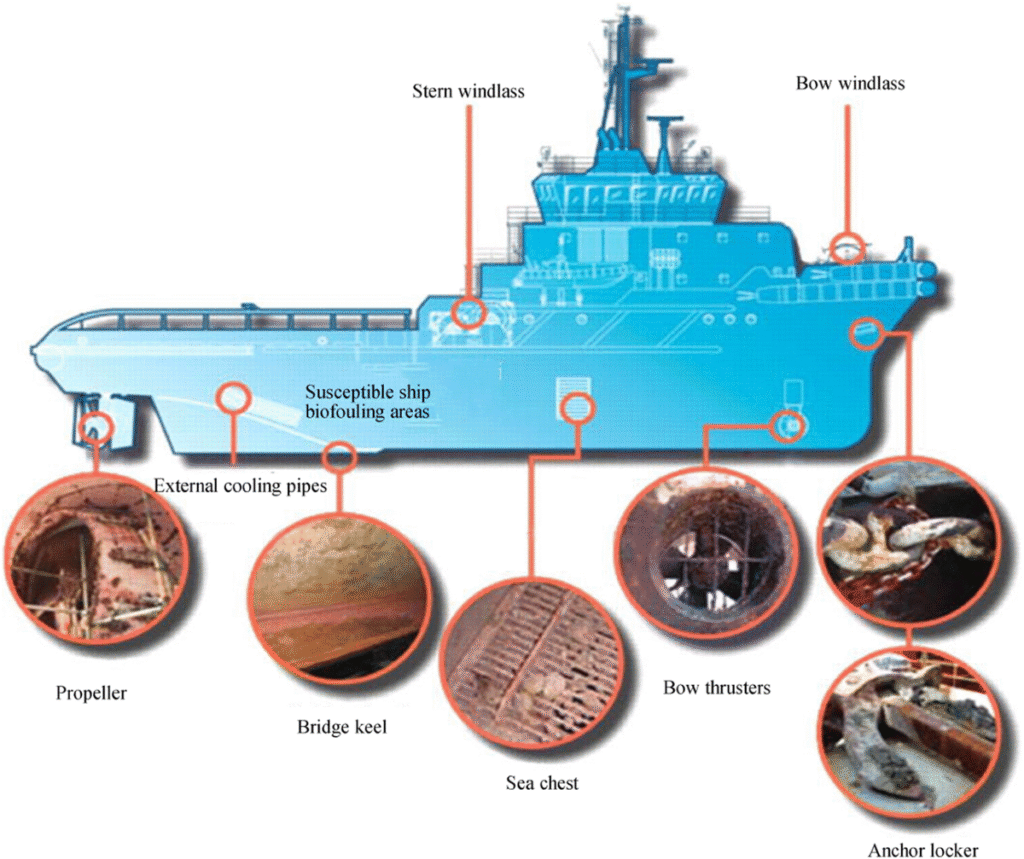

Why Hull Cleaning Cannot Be Ignored

Hull cleaning isn’t cosmetic—it’s fundamental to vessel performance. Biofouling is like cholesterol in human arteries: it builds silently and clogs efficiency.

- Fuel consumption: According to the International Maritime Organization (IMO), heavy biofouling can increase consumption up to 40%.

- Higher emissions: More fuel means more CO₂, NOₓ, and SOₓ emissions—complicating compliance with MARPOL Annex VI.

- Regulatory pressure: Ports and regional authorities are tightening rules on invasive species transfer through hull fouling.

- Operational costs: Lost speed on a global voyage can cost shipping operators millions each year.

In short: clean hulls save money, ensure compliance, and protect the environment.

Traditional Methods and Their Drawbacks

For decades, hull cleaning meant sending divers underwater with brushes, scrapers, or high-pressure water tools. While effective, this approach has big limitations:

- Safety risks: Divers face entanglement, low visibility, and decompression dangers.

- Coating damage: Brushes and scrapers can wear down anti-fouling paints prematurely.

- Environmental harm: Scrubbed biofouling may drift into harbors, introducing invasive organisms.

- Operational downtime: Cleaning requires coordination, delaying voyages.

It’s a case of good intentions wrapped in inefficiency. This is where automation steps in with Robotic Hull Cleaning.

What is Robotic Hull Cleaning?

Robotic Hull Cleaning uses unmanned, magnetically adhered, or suction-based robots to clean hulls underwater. These systems are equipped with cameras, sensors, and specialized cleaning nozzles or brushes.

Think of them as high-tech underwater geckos: clinging firmly to hull surfaces, gliding across them with precision, and leaving behind smooth metal free of fouling.

Also read about underwater hull cleaning in Ecuador.

Key features often include:

- Non-abrasive cleaning tools (water jets, soft brushes).

- Real-time video monitoring.

- Biofouling waste capture for eco-friendly disposal.

- Automated navigation with GPS or sonar assistance.

Unlike divers, robots don’t get tired and don’t cut corners. Read more.

HullWiper: A Revolution in Eco-Friendly Cleaning

Developed in Dubai, HullWiper has become one of the most recognized Robotic Hull Cleaning systems.

How it works:

- Uses adjustable seawater jets (instead of brushes) to dislodge biofouling.

- Equipped with ROV (Remotely Operated Vehicle) technology for precise remote control.

- Collects waste material through a built-in filtration system, preventing invasive species transfer.

Benefits of HullWiper:

- No coating damage: Water jet technology is gentler on anti-fouling paints compared to scraping.

- Environmental compliance: Waste capture ensures MARPOL and IAPH regulations are followed.

- 24/7 operation: Can clean day or night, in port waters, without harming marine life.

- Efficiency: Ships can often undergo cleaning while docked for cargo loading.

HullWiper has been approved in numerous ports worldwide, reflecting trust from port authorities concerned with environmental safety.

Groom: Proactive Hull Grooming Technology

While HullWiper excels at reactive cleaning, Groom is designed around prevention. Grooming systems use Robotic Hull Cleaning units with soft brushes or gentle suction systems that continuously prevent the establishment of biofouling.

How Groom works:

- Deployed regularly, these robots glide across hulls at scheduled intervals.

- They disrupt the earliest stages of slime growth, stopping barnacles and algae before they become entrenched.

- Because fouling is never allowed to spread, deep and aggressive cleaning becomes unnecessary. Learn more.

Benefits of Groom:

- Continuous efficiency: Ships maintain optimal performance without dips in fuel economy between cleanings.

- Coating preservation: Gentle grooming extends the lifespan of expensive coatings.

- Reduced invasive species risk: Preventive cleaning means less biomass buildup.

- Cost-effective: Little-and-often cleaning avoids costly downtime for major hull maintenance.

Groom embodies the wisdom of prevention over cure—far cheaper long-term.

Comparing HullWiper and Groom

| Feature | HullWiper | Groom |

|---|---|---|

| Primary Role | Reactive hull cleaning | Preventive hull grooming |

| Method | High-pressure seawater jets + ROV | Gentle robotic brushing/suction |

| Environmental Impact | Captures and filters fouling waste | Prevents fouling from establishing |

| Ideal Use Case | Vessels with established fouling | Vessels seeking to avoid buildup |

| Coating Safety | Non-abrasive, water-based jets | Ultra-gentle continuous grooming |

Both have unique strengths. HullWiper is like a surgeon removing a tumor; Groom is like a personal trainer keeping the patient fit in the first place.

Regulatory and Environmental Compliance

Compliance is no minor detail—it’s the backbone of Robotic Hull Cleaning adoption. Organizations like the IMO, IAPH, and standards groups like IMCA insist on minimizing invasive species spread.

Both HullWiper and Groom support compliance by:

- Limiting or preventing fouling release into surrounding waters.

- Supporting IMO’s biofouling management guidelines.

- Ensuring ships meet fuel-efficiency targets under MARPOL greenhouse gas frameworks.

As scrutiny tightens, embracing these systems becomes not just optional but essential.

The Business Case for Robotic Hull Cleaning

From a ship management perspective, the case is clear:

- Fuel efficiency: Cleaner hulls cut drag, increasing speed per fuel ton.

- Reduced dry-docking: Robotic cleaning can be performed in-port, avoiding costly haul-outs.

- Lower labor risks: With divers out of the equation, companies reduce liability and insurance risks.

- Reputation for sustainability: In an era of ESG metrics, being green isn’t optional—it’s expected.

Consider this: A large container ship spends tens of millions yearly on fuel. If Robotic Hull Cleaning saves even 8–12% of that, the payback is immediate and ongoing.

At Marine Super Cargo, we provide trusted marine cleaning solutions across 1,100+ ports worldwide. From hold cleaning to underwater hull cleaning and tank cleaning, our services are designed to keep your fleet fully compliant, efficient, and cargo-ready. pic.twitter.com/N5VYZZjlQH

— Marine Super Cargo (@Marinsupercargo) September 11, 2025

Challenges and Limitations

No technology is flawless. Some challenges include:

- High initial investment in robotic systems.

- Training requirements for crews to operate ROVs or automated units.

- Port restrictions where unmanned cleaning robots still require regulatory approval.

- Hull design compatibility—unusual geometries may complicate robot operation.

Still, ongoing R&D is streamlining costs and boosting global acceptance.

The Future of Robotic Hull Cleaning

Looking ahead, the shipping world is sailing into a fully automated era. The next wave of Robotic Hull Cleaning developments may include:

- Autonomous AI navigation—robots that map hulls, predict fouling hotspots, and clean without human oversight.

- Integrated inspection and reporting—cleaning bots delivering instant digital health reports of hull conditions.

- Smart port services—automated cleaning drones deployed systematically at major hubs.

- Hybrid systems—combining cavitation jets, brushes, and suction cleaning in a single robotic platform.

The future is less about fighting fouling and more about ensuring it never gets a foothold in the first place.

Conclusion

Robotic Hull Cleaning is no longer just futuristic thinking—it’s today’s smarter, safer, and more sustainable hull maintenance solution. Systems like HullWiper and Groom prove that proactive and reactive robotics can work hand in hand to save costs, preserve coatings, and ensure environmental compliance.

3 Key Takeaways:

- Robotic cleaning improves safety, efficiency, and environmental responsibility.

- HullWiper and Groom offer complementary approaches—reactive and preventive.

- Cleaner hulls directly translate into fuel cost savings and IMO compliance.

To future-proof your fleet with sustainable, innovative hull maintenance, explore more insights at CleanShip.co.

FAQ:

Q1. What is Robotic Hull Cleaning?

It is the use of underwater robots equipped with brushes, jets, or suction systems to remove fouling from ship hulls, improving efficiency and compliance.

Q2. How does HullWiper differ from Groom?

HullWiper uses seawater jets to clean existing fouling, while Groom prevents fouling buildup through frequent, gentle grooming.

Q3. Is Robotic Hull Cleaning eco-friendly?

Yes. Both HullWiper and Groom prevent invasive species spread and reduce ship emissions by maintaining smooth hull surfaces.

Q4. Can Robotic Hull Cleaning replace divers entirely?

In many cases, yes. Robots minimize the need for risky diver interventions, though complex scenarios may still require human oversight.

Q5. What’s next for Robotic Hull Cleaning?

The future includes AI-driven autonomous robots, predictive cleaning systems, and integration with port automation for seamless maintenance.