Think of a ship’s hull as the lungs of the vessel. When clean, it breathes freely through the water, cutting smoothly across oceans. But when covered in barnacles, algae, or slime, it’s like breathing with a blocked nose—inefficient, costly, and exhausting. Traditionally, we clean the hull reactively, after fouling slows us down. But what if we could predict fouling before it becomes a problem? That’s the promise of Predictive Fouling Management powered by AI and machine learning.

In this guide, we’ll dive into how cutting-edge technology is transforming hull maintenance. You’ll see how predictive systems forecast fouling growth, optimize cleaning schedules, and help ship owners stay compliant while reducing costs and emissions.

Why Fouling Matters

Marine fouling may look like nothing more than a layer of slime, but its impacts are profound:

- Fuel Penalties: Fouling increases drag, forcing engines to burn more fuel—sometimes 15–30% more.

- Higher Emissions: More fuel means higher CO2, NOx, and SOx emissions, directly affecting IMO’s CII and EEXI ratings [imo.org].

- Regulatory Trouble: MARPOL Annex V restricts uncontrolled hull cleaning waste disposal [Marine Insight – MARPOL Convention].

- Invasive Species Risk: Organisms riding on hulls travel across ecosystems and destabilize environments [iaphworldports.org].

In short, ignoring fouling is like ignoring debt—it grows silently until it’s unmanageable.

From Reactive to Predictive Maintenance

In the past, hull management followed fixed schedules: clean every six months, inspect at dry-dock, repaint every other cycle. But the ocean doesn’t follow calendars. Biofouling accelerates in warm waters, slows in colder ones, and varies by trade route.

That’s why static models fail. What ships need is Predictive Fouling Management—a data-driven approach that learns patterns and adapts proactively.

What is Predictive Fouling Management?

At its core, Predictive Fouling Management combines maritime data with advanced analytics. AI and machine learning systems use historical voyage data, environmental parameters, and real-time hull performance to forecast fouling growth.

Think of it as a weather forecast, but for hull cleanliness. Instead of waiting for barnacles to appear, the AI predicts when and where they’re likely to colonize, letting operators act just in time.

How Predictive Fouling Management Works

- Data Inputs:

- Speed, draft, trim, and fuel consumption

- Water conditions: salinity, temperature, turbidity

- Past fouling growth records

- Paint/coating history

- AI Analysis: Machine learning models identify fouling risk patterns.

- Prediction Output: Operators receive alerts like: “Predicted fouling growth will increase drag by 8% within 2 weeks in tropical waters.”

- Decision Support: Crews plan proactive cleaning, adjust speed, or alter routes.

That’s the essence—decision-making based on insight, not hindsight.

Benefits of Predictive Fouling Management

- Cost Savings: Reduces unnecessary cleaning, saving up to 20% on OPEX.

- Fuel Efficiency: Ensures vessels stay as close as possible to baseline fuel performance.

- Environmental Gains: Cuts emissions significantly, aligning with IMO decarbonization goals [imo.org].

- Compliance Assurance: Supports MARPOL Annex V and biofouling guidelines by avoiding last-minute, uncontrolled cleaning.

- Invasive Species Control: Cleaning is done strategically and legally to reduce ecological risks.

Challenges in Traditional Hull Maintenance

Without predictive tools, operators face problems:

- Cleaning too late means higher costs and more downtime.

- Cleaning too early wears down protective coatings.

- Inaccurate schedules risk regulatory non-compliance.

- Reactive strategies lead to wasted manpower and higher diver or ROV costs [imca-int.com].

Predictive models solve these headaches by aligning hull care with science-backed timelines.

Role of AI and Machine Learning

Machine learning thrives on patterns. Once trained with years of fouling and voyage data, algorithms can predict:

- Which ports and waters increase fouling risk

- How long will specific coatings resist growth in certain climates

- When hull roughness crosses thresholds affecting efficiency

- Best months for preventive cleaning on specific routes

In other words, it connects the dots humans might miss—like a chess player who always thinks five moves ahead.

Integrating with Hull Performance Monitoring

Predictive foul management doesn’t work alone; it integrates seamlessly with Hull Performance Monitoring systems. Together, they provide a closed loop:

- Monitoring software measures real-time performance losses.

- Predictive systems forecast future fouling growth.

- Actions (like cleaning or routing changes) recalibrate performance baselines.

It creates a continuous cycle of anticipate–measure–act–optimize.

Case Study: Tanker in the Indian Ocean

A tanker operating tropical routes saw fouling spikes every 3–4 months. By deploying Predictive Fouling Management, the operator discovered fouling correlated strongly with seasonal algae blooms along its routes.

- Cleaning was rescheduled proactively every 10 weeks instead of 12.

- Fuel savings: nearly $600,000 per year.

- CO2 cut: 2,100 metric tons annually.

AI didn’t just predict fouling—it turned predictable inefficiency into a strategic advantage.

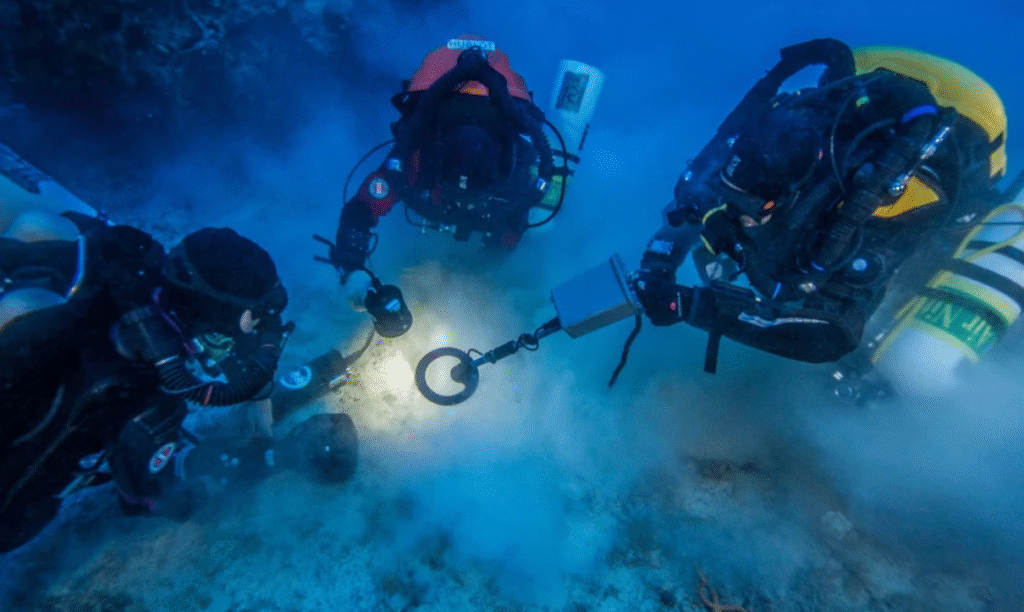

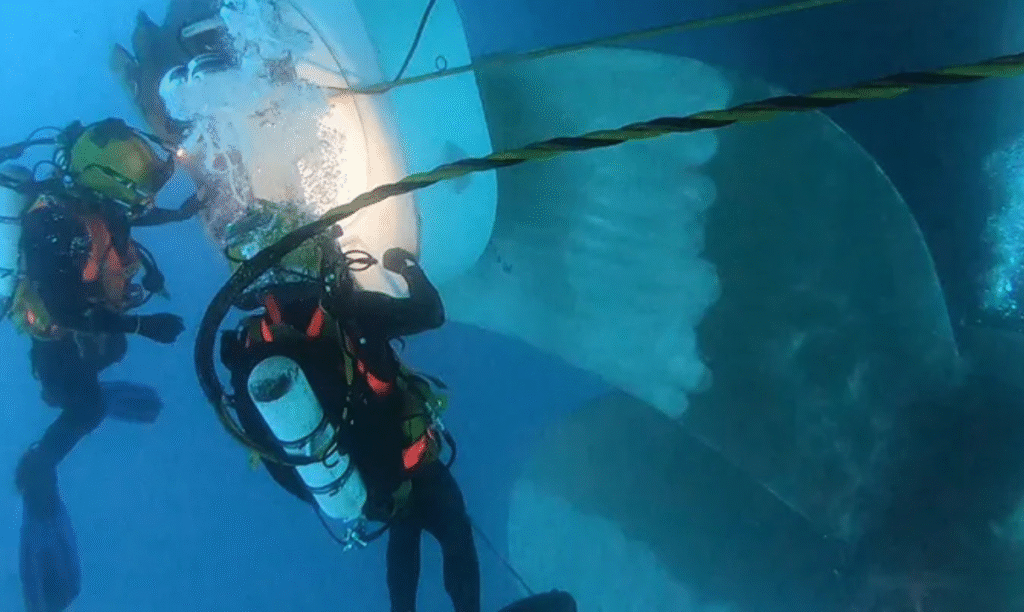

⚓ Expert Underwater Hull Cleaning with Marine Super Cargo 🌊

— Marine Super Cargo (@Marinsupercargo) September 19, 2025

A clean hull means better performance, lower fuel use, and smoother voyages. Marine Super Cargo offers top Underwater Hull Cleaning to keep your vessel efficient, compliant, and ready for every operation. pic.twitter.com/sVKAUCytuS

Compliance and Regulation

Authorities are paying attention:

- IMO Guidelines (2011): Stress risk-based inspection and cleaning.

- MARPOL Annex V: Cleaning waste must be collected and properly disposed.

- IMCA Recommendations: Favor safe, efficient alternatives like predictive inspections.

- IAPH Initiatives: Encourage adoption of digital and predictive tools in major ports worldwide.

Predictive fouling management dovetails neatly with this regulatory trend.

Innovations & Future Trends

The next wave of maritime AI promises even more breakthroughs:

- Hybrid AI Models: Combining fouling data with satellite oceanographic inputs.

- Digital Twins: Virtual replicas of ships modeling fouling behavior under different scenarios.

- Automated Cleaning Systems: AI-predicted cleaning needs linked to robotic underwater cleaners.

- Blockchain Logging: Tamper-proof fouling management reports shared with ports and regulators.

- Self-learning Coatings: New paints integrated with sensors that report their biofouling resistance.

These aren’t distant dreams—they’re already in pilot testing.

Operational Best Practices

To capitalize on Predictive Fouling Management:

- Establish clean-hull performance baselines for each vessel.

- Feed regular performance, route, and climate data into AI systems.

- Use predictive alerts to plan targeted inspections and cleaning.

- Align cleaning schedules with port waste management facilities for Annex V compliance.

- Train crews on digital dashboards for easy interpretation of system outputs.

Doing so makes risk management proactive instead of reactive.

Why This Matters Now

Global shipping is under unprecedented scrutiny. Fuel costs are rising, decarbonization deadlines loom, and port authorities are stricter than ever about invasive species. Reactive hull care is no longer enough. AI-guided Predictive Fouling Management gives fleets the foresight they need to stay efficient, compliant, and future-ready.

Conclusion

The oceans demand agility, and ships can no longer afford to manage fouling on outdated calendars. Predictive Fouling Management is the future—combining AI and machine learning to forecast fouling risks and align cleaning with real-time needs. Key takeaways:

- Predictive analytics shift fouling management from reactive to proactive.

- AI-driven foresight reduces costs, emissions, and invasive species risks.

- Adoption supports compliance with IMO, MARPOL, and port initiatives.

To harness these benefits, partner with innovators like CleanShip.co, who specialize in sustainable, data-driven solutions.

FAQs:

Q1. How accurate are predictive fouling models?

With sufficient data inputs, AI models can forecast fouling growth with high accuracy, often within a margin of 5–10% from actual outcomes.

Q2. Does predictive fouling management replace hull cleaning?

No, it optimizes cleaning by predicting the right time and place to carry it out, minimizing costs and risks to coatings.

Q3. Is this technology expensive to adopt?

Initial investment exists, but fuel and OPEX savings typically offset costs within one to two years, making it highly cost-effective.

Q4. Can predictive fouling tools integrate with existing ship systems?

Yes, most platforms integrate easily with hull performance monitoring software and vessel data hubs for seamless operations.

Q5. What’s the future of fouling management?

Expect AI integration with robotic cleaners, eco-friendly coatings, and real-time regulatory reporting, making fouling control mostly autonomous.