For centuries, ship operators have fought a quiet battle against the sea—not just storms and currents, but hull fouling. Barnacles, algae, and slime may seem minor, yet they drag ships down, waste fuel, and increase emissions. Today, the battle is transforming, thanks to digital allies like Hull Performance Monitoring software. When combined with proactive hull cleaning, this technology creates a synergy that’s reshaping efficiency, compliance, and environmental stewardship.

In this article, we’ll explore how linking cleaning schedules with performance data unlocks measurable gains, why this matters for compliance and costs, and where the future of maritime maintenance is headed.

Why Hull Cleaning Still Matters

Imagine driving your car with mud caked on the tires and body. Even though the engine is fine, you’ll burn more fuel and wear down faster. Hull fouling works the same way. A dirty hull increases resistance, which forces engines to work harder and consume more fuel.

- Barnacle fouling can increase drag by up to 40%.

- Even thin biofilms can hike fuel use by 10%.

- Fouling pushes CO2 emissions higher, undermining fleets’ compliance with the IMO’s Carbon Intensity Indicator (CII).

Regular hull cleaning reduces drag, but cleaning at the right time is where the magic really happens—that’s where Hull Performance Monitoring steps in.

The Concept of Hull Performance Monitoring

So, what exactly is Hull Performance Monitoring? Think of it as your ship’s fitness tracker. Just as wearables measure heart rate and calories burned, this software measures and analyzes how clean—or fouled—your hull is and how it affects fuel efficiency.

Key Parameters Tracked Include:

- Vessel speed versus fuel consumption

- Hull roughness and fouling indices

- Propeller efficiency (often fouling hotspots)

- Environmental conditions like water temperature and salinity

- Long-term performance trends per voyage or season

By integrating hull cleaning operations with this data, owners no longer rely on guesswork—they rely on evidence. Also read about underwater hull cleaning in France.

The Old Model: Cleaning by Calendar

Historically, hull cleaning has followed a calendar-based schedule: every six months, every dry-dock, or after certain voyages. While better than neglect, this method is flawed.

- Sometimes cleaning is done too late, and efficiency losses pile up.

- Sometimes it’s too early, wasting time and damaging coatings.

- Operators often lacked accurate fouling data for decision-making.

It’s like visiting your doctor only because it’s on the calendar, not because your body shows symptoms. Hull Performance Monitoring makes cleaning smarter—not scheduled, but needed.

⚓ Expert Underwater Hull Cleaning with Marine Super Cargo 🌊

— Marine Super Cargo (@Marinsupercargo) September 19, 2025

A clean hull means better performance, lower fuel use, and smoother voyages. Marine Super Cargo offers top Underwater Hull Cleaning to keep your vessel efficient, compliant, and ready for every operation. pic.twitter.com/sVKAUCytuS

Benefits of Integrating Monitoring with Cleaning

When cleaning aligns with real-time hull data, the results are powerful:

- Fuel Savings: Timely cleaning can cut fuel use by 5–15%.

- Regulatory Compliance: Helps meet IMO’s efficiency rules and MARPOL Annex V requirements for cleaning waste disposal.

- Lower OPEX: Avoids premature coating wear or unnecessary diver operations.

- Strategic Planning: Data trends help plan dry-dockings and future maintenance.

- Reduced Emissions: Directly contributes to decarbonization and sustainability goals under IMO and IAPH.

In other words, Hull Performance Monitoring combined with cleaning is like tuning your piano only when the notes go off-key—efficient, logical, and cost-smart.

How Hull Performance Monitoring Works in Practice

- Data Collection: Sensors and ship logs feed real-time speed, power, and environmental input to the monitoring software.

- Analysis: The system compares current performance to baseline “clean hull” benchmarks.

- Alerts: When losses exceed thresholds, operators are notified about possible fouling.

- Action: This data informs whether in-water cleaning or dry-docking is needed.

- Feedback Loop: Post-cleaning, performance data resets baselines for continuous tracking.

This cycle ensures cleaning decisions are data-led and transparent.

Compliance Drivers

Authorities are increasingly pushing for smarter hull management:

- IMO’s Biofouling Guidelines (2011): Encourage performance-based cleaning schedules.

- MARPOL Annex V: Regulates waste disposal from hull cleaning.

- IMCA Guidance: Endorses robust monitoring as part of safe in-water cleaning.

- IAPH Port Standards: Ports are investing in digital solutions to encourage compliant cleaning practices.

Integrating cleaning with Hull Performance Monitoring not only saves money but also protects operators against compliance risks.

The Environmental Perspective

Biofouling isn’t just an efficiency problem—it’s a vector for invasive species. Ships carry organisms from one port ecosystem to another, creating ecological risks. To mitigate this, Hull Performance Monitoring helps ensure cleaning is neither too frequent (wasting resources) nor too infrequent (spreading species).

By striking the right balance, operators reduce emissions, protect biodiversity, and support IMO decarbonization targets.

Real-World Case Study

A bulk carrier operating in the Pacific installed Hull Performance Monitoring software integrated with predictive maintenance. The data showed efficiency dropping 6% within three months due to unexpected fouling in warm equatorial waters. Instead of waiting for the scheduled dry-dock, operators arranged targeted in-water cleaning.

Results:

- Fuel consumption dropped back to baseline.

- Savings of $400,000 annually in fuel costs.

- Reduced CO2 emissions by 1,700 metric tons.

This showcases how data-driven cleaning transforms efficiency from reactive to proactive.

Innovations and Future Trends

Maritime technology is evolving, and hull care is no exception. Innovations include:

- AI Learning Algorithms: Predict fouling based on trade route and water conditions.

- Drone-Assisted Monitoring: Seamless mapping of niche areas before cleaning.

- Digital Twins: Entire virtual hulls to simulate how fouling affects performance and cleaning needs.

- Eco-Friendly Cleaning Robotics: Autonomous machines guided by performance analytics.

- Blockchain Logs: Immutable compliance records documenting cleaning linked with hull performance data.

In the next decade, Hull Performance Monitoring will integrate even deeper into predictive fleet management.

Cost-Management and Investment Payback

Yes, monitoring software requires upfront investment, but savings quickly offset it:

- 5–10% reduction in fuel per voyage

- Fewer unscheduled dry-docks

- Optimal coating maintenance, extending paint life cycles

- Lower environmental penalties and inspection delays

It’s the difference between changing your car oil only when diagnostics say it’s due versus blindly replacing it every month. Over time, the smart approach always wins.

Best Practices for Operators

To maximize gains, ship operators can:

- Define baseline performance after fresh cleaning or dry-docking.

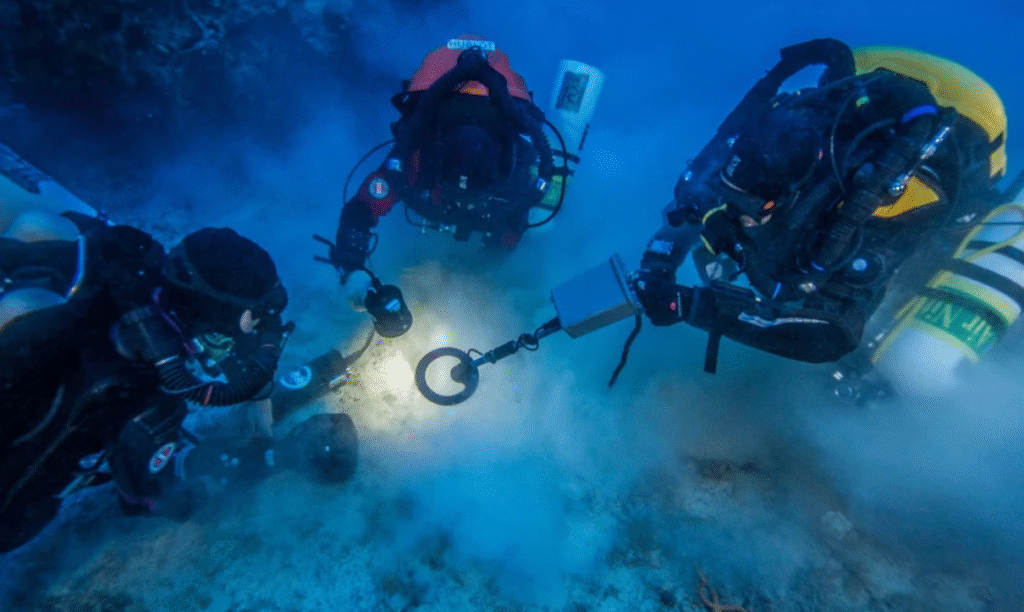

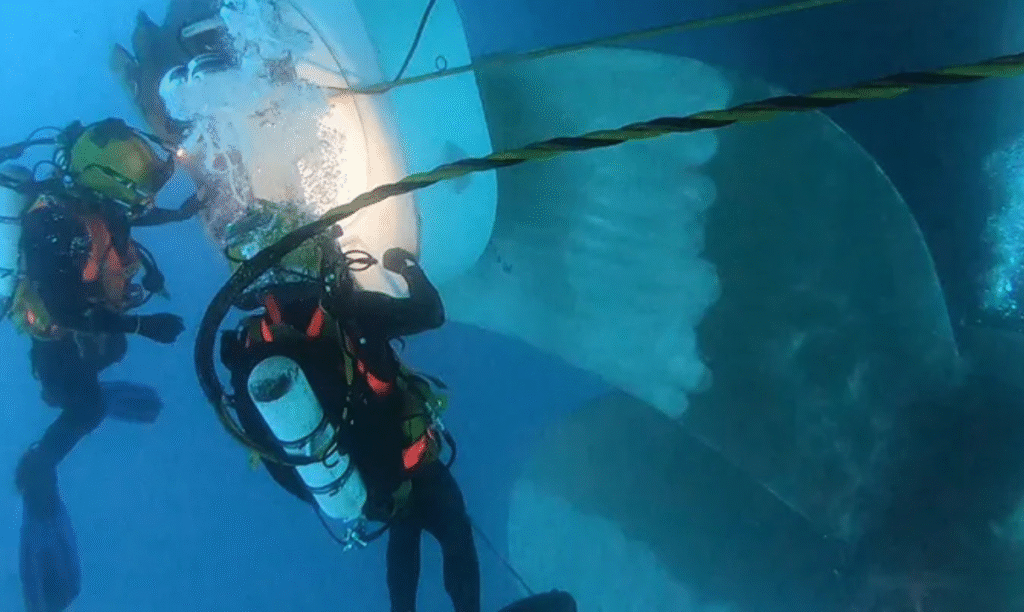

- Combine diver/ROV inspections with hull monitoring alerts.

- Share monitoring data transparently with regulators and cleaning vendors.

- Train crews to interpret monitoring dashboards.

- Dispose of biofouling waste in accordance with MARPOL obligations.

When done right, cleaning becomes a precision tool, not a blunt one.

Conclusion

Integrating hull cleaning with Hull Performance Monitoring offers a triple advantage: it saves fuel and costs, ensures compliance, and slows environmental impact. The key takeaways are clear:

- Monitoring shifts, cleaning from guesswork to a data-driven strategy.

- Properly timed cleaning minimizes emissions while maximizing efficiency.

- Investing in digital solutions pays back quickly through savings and compliance security.

For fleets serious about performance and compliance, solutions from experts like CleanShip.co offer a sustainable pathway forward.

FAQs:

Q1. How often should hull performance data be collected?

Ideally, data is collected continuously, with daily summaries. This ensures operators spot efficiency drops quickly and adjust cleaning schedules accordingly.

Q2. Does hull monitoring replace physical inspections?

No, it complements them. Monitoring highlights when fouling is likely, while inspections or drones confirm the actual extent.

Q3. Can this integration help with IMO CII ratings?

Absolutely. Better hull efficiency directly improves CII scores, making monitoring essential for compliance and competitiveness.

Q4. Will using the software extend coating life?

Yes, because operators avoid unnecessary cleaning that erodes protective paint layers, thereby prolonging coating performance.

Q5. What’s the biggest future trend in hull monitoring?

Integration with AI and digital twins, enabling predictive schedules based on environment, trade routes, and hull history.