Imagine running a global shipping operation, with your vessels crossing oceans and tight schedules to meet. Now picture being blindsided by heavy fines—not just for missing a port deadline, but because Poor Hull Maintenance led to increased emissions or invasive species transfer.

Suddenly, what seemed like a harmless delay in cleaning turns into a financial storm. Let’s unpack why Poor Hull Maintenance is one of the most expensive mistakes you and I can make in maritime operations, and how you can steer clear of these pitfalls.

What Is Poor Hull Maintenance?

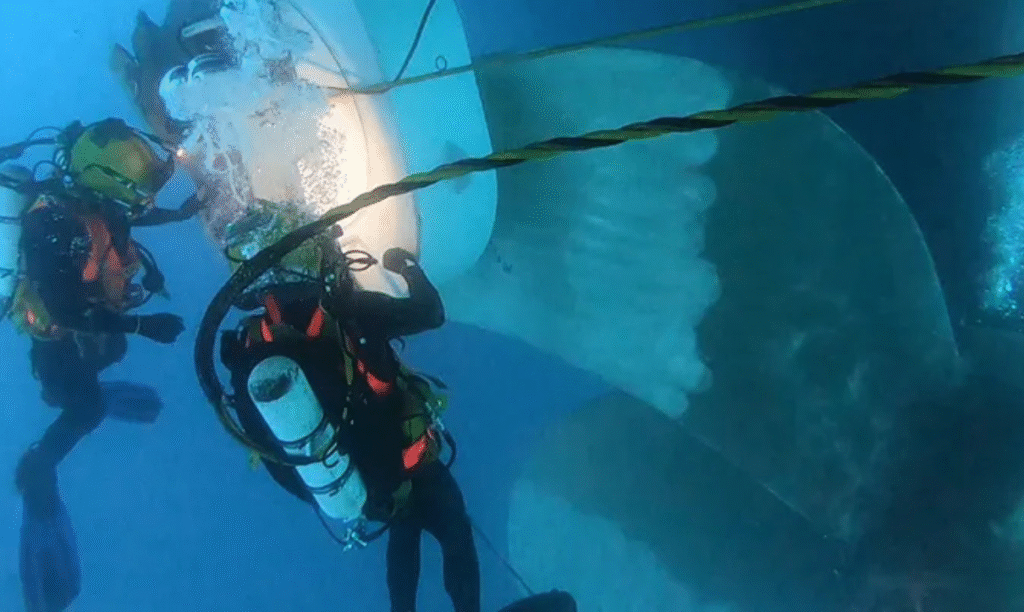

Poor Hull Maintenance means neglecting regular cleaning and inspections of a ship’s underwater hull, allowing biofouling (marine growth like barnacles and algae) or corrosion to accumulate. This is more than a cosmetic issue—it drags fuel efficiency down, wears out coatings, and can push vessels out of compliance with international standards like MARPOL and IMO biofouling guidelines.

The Hidden Financial Dangers of Poor Hull Maintenance

Ignoring hull upkeep has ripple effects across your operations and profit margins. Here’s what it really costs:

- Hefty Fuel Bills: Biofouling can lead to up to 20% higher fuel consumption, inflating one of your largest variable costs each month.

- Performance Penalties: Many charter party contracts now suspend speed and consumption warranties when biofouling is not managed, often resulting in direct compensation claims or loss of hire.

- Environmental Fines: Emission breaches linked to Poor Hull Maintenance can attract regulatory penalties and limit port access, especially as IMO and EU decarbonisation targets tighten.

- Insurance Claim Reductions or Denials: Hull insurance claims may be denied or paid at a reduced rate if Poor Hull Maintenance is found to be a contributing factor, exposing you to unrecoverable losses.

- Loss of Business: Failure to meet green charter standards or port regulations due to Poor Hull Maintenance can mean cancelled contracts and fewer future opportunities.

Understanding Compliance Penalties

Shipping is facing a tidal wave of new hull management regulations. MARPOL and IMO’s biofouling guidelines are stricter than ever, with policies in regions like New Zealand, California, and Australia banning vessels with fouled hulls or levying substantial fines. Some consequences include:

- Fines for Non-Compliance: Ports can fine or refuse berthing for vessels in violation of biofouling, emissions, or invasive species regulations.

- Delayed Operations: Badly fouled hulls can trigger extra inspections, denied entries, or ordered drydockings, pushing you off schedule and incurring extra costs.

How Poor Hull Maintenance Hits Your Bottom Line

A small patch of biofouling on the hull can increase engine load, fuel burn, and emissions dramatically. Poor Hull Maintenance directly impacts:

- Fuel Costs: Even modest fouling reduces hydrodynamic efficiency, causing excess fuel use—often unnoticed until huge bills arrive.

- Maintenance Overruns: Hull coatings degrade faster, drydockings are more frequent, and long-term repair costs mount up.

- Schedule Risks: Slower ships can’t keep up, requiring costly workarounds or rescheduling that hurts customer trust.

- Data-Driven Penalties: New digital monitoring means authorities and charterers can quickly prove when Poor Hull Maintenance is dragging your performance down, triggering instant penalties.

Real-World Example: Penalty Clauses Triggered by Neglected Hulls

A major fleet operator remained at anchor in tropical waters beyond the allowed durations in the charter contract. They failed to conduct timely hull cleaning or inspections. The result? Not only were performance warranties suspended, but when underwater surveys showed heavy fouling, the charterers demanded compensation for lost speed and excess fuel burned. In some cases, a lump sum payment is negotiated if cleaning cannot be completed before contract redelivery. Also, read about underwater hull cleaning in Cochin.

The Regulatory Net Tightens

International maritime bodies like IMO and environmental regulators are closing loopholes:

- Required underwater inspections every 12-18 months, more frequent for poorly maintained hulls.

- Cleaning logs, photos, and surveys must be meticulously updated and ready for inspection.

- Failing these standards? Expect delays, hefty re-cleaning costs, and potential legal disputes.

✅ 4 Things to Check for Safety at Sea pic.twitter.com/dAxhJQ2i6U

— Marine Super Cargo (@Marinsupercargo) September 14, 2025

Preventing Financial Penalties: Proven Solutions

Smart, proactive hull cleaning systems are booming. Here’s what works:

- Routine Cleaning: Stick to scheduled hull maintenance, especially after extended port stays or tropical anchorage.

- Digital Monitoring: Adopt AI-based sensors and logs to track biofouling and trigger timely interventions.

- Robotic and Closed-Loop Systems: Use non-invasive, eco-friendly cleaning robots to meet port authority requirements and avoid spreading invasive species.

- Right Coatings: Apply advanced hull coatings that slow fouling and cut cleaning frequency and costs.

Future Trends in Hull Maintenance and Compliance

The hull maintenance landscape is being reshaped by:

- Automation & Robotics: Unmanned vehicles perform regular, precise cleaning, reducing human risk and error.

- Predictive Analytics: Data-driven planning models prevent overspending on unnecessary cleaning while ensuring compliance.

- Regulatory Convergence: Expect global biosafety, emissions, and fuel efficiency standards to become stricter, with higher penalties for non-compliance.

- Green Performance Metrics: Penalties for Poor Hull Maintenance may soon include carbon taxes and digital tracking, putting compliance at the core of profitable operations.

Heading Placeholders for In-Depth Sections

- What Is Poor Hull Maintenance?

- The Direct Costs of Neglecting Hulls

- Compliance Penalties Explained

- Insurance Pitfalls and Claim Denials

- Real-World Case Studies in Penalty Triggers

- Proactive Solutions: Preventing Penalties

- Innovations and the Future of Hull Compliance

Technical Jargon Explained

- Biofouling: Marine growth, such as barnacles and algae, that attaches to the hull and increases drag.

- Hydrodynamic Resistance: Extra force needed to move a ship through water when surfaces are rough or fouled.

- Closed-Loop Cleaning: A system that captures biofouling debris during cleaning to prevent contamination of marine habitats.

- AFS (Antifouling System): Special coatings or treatments applied to hulls to prevent or slow down biofouling.

Conclusion

Choosing to defer hull cleaning might save money today, but it guarantees steep financial penalties in the long run. Poor Hull Maintenance leads to fuel inefficiencies, regulatory fines, and contract breaches that erode profits and reputation. By embracing smart maintenance practices and leveraging innovations, you can protect both your fleet’s bottom line and the oceans. For the most reliable compliance and cost-saving solutions, partner with CleanShip.co and sail ahead of costly mistakes.