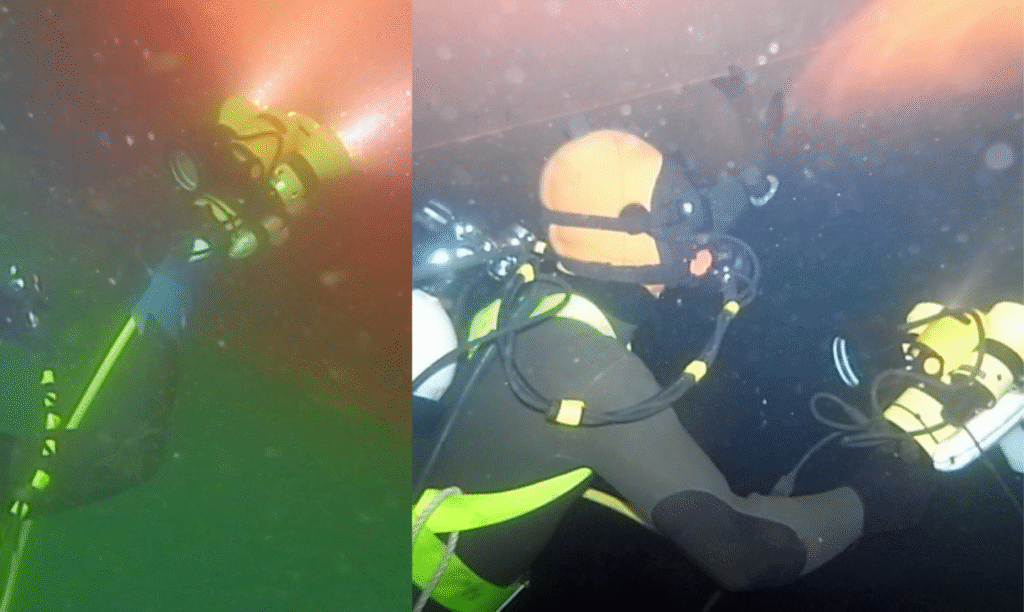

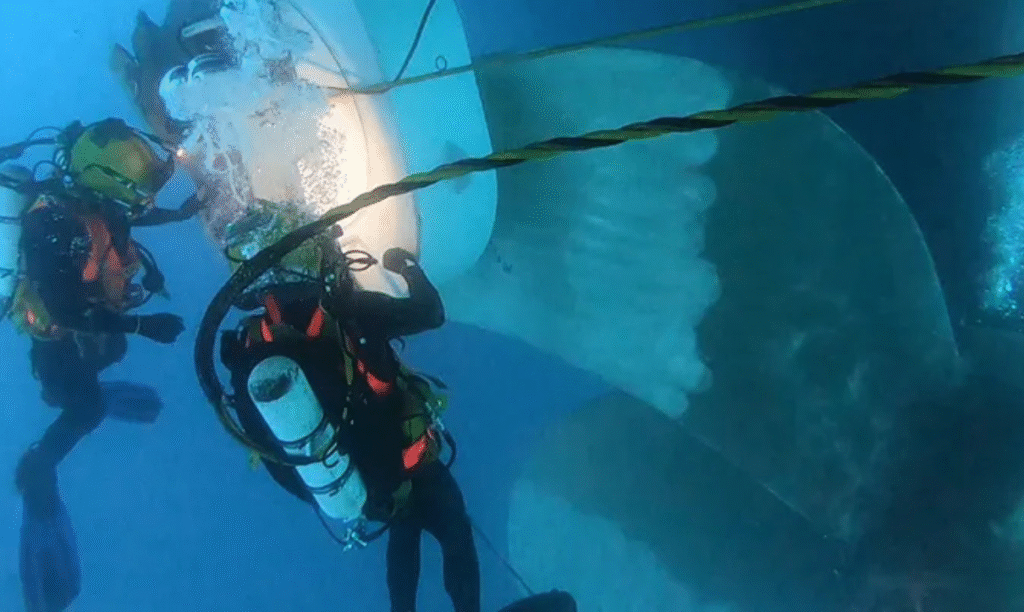

Picture this: a massive cargo ship anchored at port, its hull covered with a stubborn layer of barnacles and biofouling. The crew prepares divers, tools, and safety gear, while the clock ticks and port authorities expect compliance with strict environmental rules. In these moments, Hull Cleaning Logistics becomes the backbone of successful operations.

It’s easy to think of hull cleaning as just scrubbing and polishing. But behind the scenes, precise coordination of manpower, tools, and consumables is what ensures efficiency, safety, and regulatory compliance. This article unpacks the logistics that go into hull cleaning, offering shipowners, operators, and managers a clear roadmap to execute these tasks effectively.

Why Hull Cleaning Logistics Matter

Logistics in hull cleaning operations are about more than organization—they are about survival in a high-stakes maritime environment. Without well-coordinated Hull Cleaning Logistics:

- Divers may be exposed to unnecessary risks.

- Tools may fail mid-operation, leading to delays.

- Wasted consumables inflate costs.

- Pollution may breach MARPOL standards, placing operators at legal and reputational risk.

- Vessel turnarounds may stretch, straining port schedules.

Think of logistics as the choreography of a ballet: the divers are dancers, but timing, equipment placement, and flawless coordination form the art.

Core Elements of Hull Cleaning Logistics

To understand how Hull Cleaning Logistics work, let’s break them into three pillars: manpower, tools, and consumables.

1. Manpower: The backbone—divers, supervisors, safety officers, and crew who orchestrate each stage.

2. Tools: The equipment that makes hull cleaning possible, from hydraulic brushes to underwater vacuums.

3. Consumables: Items consumed during the job, from oxygen and cleaning pads to waste collection filters.

Success comes from balancing resources between these three categories.

Manpower in Hull Cleaning Logistics

You can’t execute effective hull cleaning without the right people in place. Standard manpower requirements include:

- Divers: Trained in underwater cleaning, biofouling removal, and emergency response.

- Diving Supervisor: Oversees safety, compliance, and coordination.

- Surface Crew: Monitors communications, manages hoses and umbilicals.

- Safety Officer: Ensures compliance with IMCA safety standards and shipboard permits-to-work.

- Waste Management Crew: Handles biofouling and debris per MARPOL Convention rules.

Special consideration must also be given to fatigue management. Long dives tire divers quickly; alternating shifts prevents human error.

Tools in Hull Cleaning Logistics

Hull cleaning equipment isn’t just “brushes.” It’s a suite of advanced tools designed to tackle specific fouling under different ship conditions. A proper logistics plan includes inspection, redundancy, and transport needs for:

- Hydraulic and Pneumatic Brushes: For scraping barnacles and hard fouling.

- Water-Jet Systems: High-pressure cleaning tools to loosen stubborn layers.

- Underwater Vacuums and Suction Systems: For collecting debris without polluting.

- ROVs (Remotely Operated Vehicles): Supporting machines to inspect difficult zones.

- Lighting and Camera Systems: For diving visibility and compliance documentation.

Tools must be pre-tested, serviced, and logged before every operation. Nothing stalls momentum like a failed hydraulic brush mid-cleaning.

Consumables in Hull Cleaning Logistics

Consumables play a subtle yet crucial role. Though they seem small, their absence can halt operations. Typical consumables include:

- Cleaning pads and abrasive discs.

- Oxygen cylinders and breathing gases.

- Filters for underwater vacuums.

- Storage drums and containers for biofouling waste.

- Protective gloves, sealants, and safety tags.

The challenge is forecasting the amount required. Oversupply bloats costs, undersupply causes dangerous midway disruption. Precise planning makes the difference.

Pre-Operation Logistics Checklist

Before diving begins, a pre-developed Hull Cleaning Logistics checklist makes sure the groundwork is solid:

- Verify manpower: trained divers, standby roles, supervisors.

- Confirm consumables are stocked for the job length.

- Transport and secure tools to the vessel location.

- Check permits-to-work and IMO/IMCA safety guidelines compliance.

- Waste management disposal plan in place.

- Communication equipment tested.

This stage builds the foundation before the first diver even enters the water. Also read about underwater hull cleaning in Australia.

On-Site Logistics Management

During active operations, coordination becomes dynamic. Logistics ensure efficiency and diver safety in constantly shifting underwater conditions:

- Tool circulation and switching via the support crew.

- Real-time monitoring of divers’ status.

- Scheduled crew rotations to prevent fatigue.

- Continuous environmental monitoring for debris or oil leaks.

- Quick solutions are ready for tool malfunction or part replacement.

Having spares and backups close at hand here is non-negotiable.

Post-Operation Logistics

After cleaning, logistics are still vital. A post-job phase includes:

- Waste transfer per MARPOL to licensed facilities.

- Equipment maintenance and servicing.

- Consumables restock list generated.

- Debriefing between crew and supervisors.

- Documentation filed for inspection and compliance audits.

This keeps ships prepared for the next hull-cleaning cycle without repeat oversights.

Compliance and Legal Framework

Logistics aren’t just operational—they’re compliance tools. Following structured Hull Cleaning Logistics proves adherence to:

- IMCA Guidelines for safe diving coordination.

- IMO marine operation standards for crew management.

- MARPOL Convention for pollution prevention.

- IAPH protocols for safe hull cleaning in port waters.

Auditable logistics records are often required during inspections. Lack of documentation can equal non-compliance.

🌊✨ Client Testimonial Spotlight ✨🌊

— Marine Super Cargo (@Marinsupercargo) September 16, 2025

💬 “The team at Marine Super Cargo feels like part of our crew. From hold cleaning to supercargo support, they handle everything seamlessly. Their quick response and reliable service saved us valuable time and money.” – Mr. Ingmar Domrös pic.twitter.com/bPlooKOakt

Case Study: Poor Logistics, Major Delay

A tanker once began underwater cleaning with only half the required consumables. Mid-dive, abrasive pads ran out. Replacement delivery took 36 hours, causing demurrage costs running into tens of thousands. Had the team prepared a consumables Hull Cleaning Logistics forecast, expensive downtime could have been avoided.

A simple oversight can snowball into major losses.

Future of Hull Cleaning Logistics

The future is digital and predictive, making logistics smarter:

- AI forecasting will calculate consumables and manpower demand precisely.

- Smart inventory systems will monitor tool and gas consumption live.

- ROV automation will reduce diver load.

- Blockchain tracking will log waste disposal per MARPOL in tamper-proof records.

- Integrated logistics platforms will link the port, the ship, and the contractors seamlessly.

These innovations will transform Hull Cleaning Logistics from reactive to predictive workflows.

Practical Guidance for Shipowners and Managers

- Always prepare manpower rotations in advance.

- Stock consumables based on realistic duration, not assumptions.

- Inspect and service tools with redundancy.

- Tie every logistic step back to compliance standards.

- Keep waste management plans updated for each port’s unique rules.

Good logistics aren’t just about efficiency—they protect profit margins and corporate reputation.

Conclusion

Behind every successful cleaning, there’s an invisible web of coordination—Hull Cleaning Logistics. Three essentials to remember are:

- Proper planning of manpower, tools, and consumables ensures smooth, safe operations.

- Compliance with IMCA, IMO, and MARPOL keeps you audit-ready and eco-friendly.

- Smart logistics cuts costs, prevents downtime, and strengthens efficiency.

For effective, sustainable cleaning, partnering with industry leaders like CleanShip.co ensures logistics aren’t left to chance but anchored in excellence.

FAQs:

Q1. Why are Hull Cleaning Logistics important?

They prevent delays, reduce risks, and ensure compliance in complex underwater cleaning projects.

Q2. How do logistics affect costs in hull cleaning?

Strong planning reduces downtime, waste, and demurrage penalties, making operations cost-efficient.

Q3. What tools are critical to hull cleaning operations?

Hydraulic brushes, underwater vacuums, water-jet systems, and ROVs are key to effective cleaning.

Q4. How does MARPOL compliance tie into logistics?

Waste storage and disposal from fouling removal must be planned and documented to avoid pollution fines.

Q5. What’s the future of Hull Cleaning Logistics?

Predictive AI, smart inventories, and digital integration linking ports, ships, and contractors will dominate.