When a diver submerges below the waterline, it’s a world vastly different from ours above. Darkness deepens, pressure changes, and hazards lurk unseen. In such an environment, a diver’s Personal Protective Equipment (PPE) isn’t just gear—it’s their lifeline.

Imagine a firefighter entering a blaze without a helmet or breathing apparatus. Impossible, right? The same applies to diving. Ignoring or underestimating PPE requirements for divers can lead to catastrophic accidents, injuries, or worse.

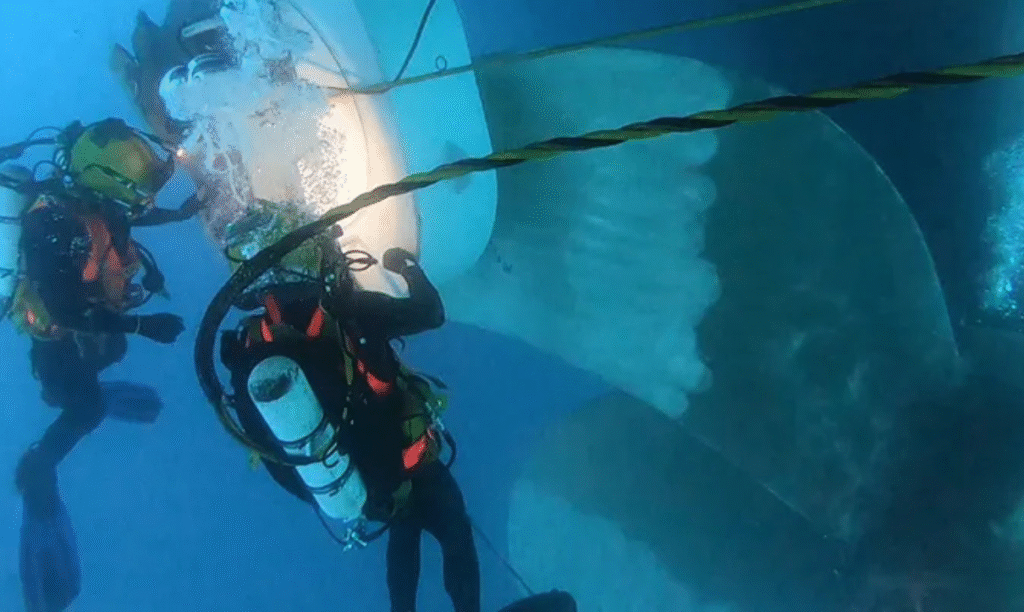

If you’re a ship owner, operator, or manager, you already know divers support activities like hull inspections, maintenance, and underwater cleaning. But ensuring their safety doesn’t stop at supervision—it extends to knowing exactly what PPE they need, why it matters, and how compliance saves not only lives but also reputations and costs.

Let’s dive deep into the essential PPE requirements for divers, compliance regulations, future innovations, and how smart planning can benefit both operational efficiency and environmental protection.

Why PPE Is Non-Negotiable in Diving

The ocean is beautiful but unforgiving. Divers face risks ranging from extreme pressure, entanglement, hypothermia, and chemical exposure to marine life stings. Without proper PPE, these hazards translate into very real injuries and operational liabilities.

By prioritizing PPE requirements for divers, you’re not simply providing gear—you’re:

- Safeguarding lives.

- Meeting IMCA, IMO, and MARPOL safety standards.

- Reducing downtime caused by accidents.

- Protecting your company from regulatory fines.

In diving, “safety margins” are built into every piece of equipment. Skipping even one component is like removing a bolt from a bridge—it might hold for a while, but failure is inevitable.

Understanding PPE Requirements for Divers

So, what do we mean by PPE requirements for divers? It’s the set of mandatory gear and support equipment worn by divers to reduce or eliminate risks during underwater operations. Unlike surface work PPE (like hard hats or safety vests), diving PPE is specialized for hostile underwater environments.

The standard equipment list broadly covers:

- Protection against pressure (helmets, suits).

- Protection against the environment (thermal gear, gloves, boots).

- Breathing apparatus and safety systems.

- Communication tools.

- Backup or redundant gear in case of emergencies.

Each piece serves a purpose—to either prevent hazards or ensure survivability if something goes wrong. Learn more.

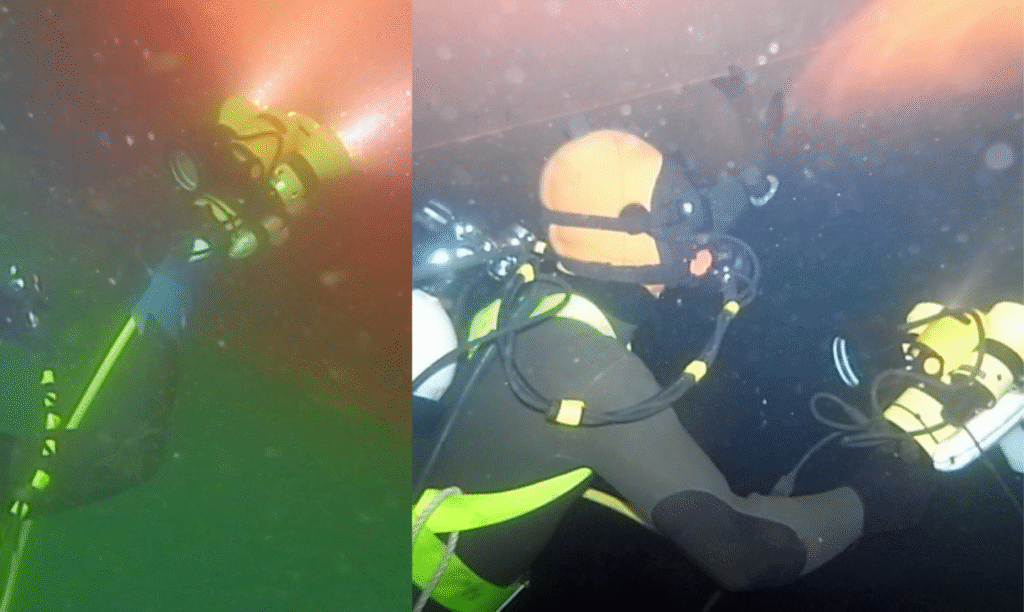

Core PPE Components Every Diver Must Wear

Let’s break down the major items included in PPE requirements for divers, and why each is non-negotiable.

- Diving Helmet or Full-Face Mask:

Provides head protection, breathing gas delivery, and often built-in communication. Helmets shield against falling debris, entanglement, and strong water currents. - Drysuit or Wetsuit:

Protects from hypothermia and abrasions. A drysuit seals the diver from cold water completely, while a wetsuit offers thermal insulation through water buffering. - Weight Belt and Harness:

Essential for buoyancy control and safety gear attachment. Without proper balancing, divers risk uncontrolled ascents or descents. - Gloves and Foot Protection:

Prevent injuries from sharp structures like barnacles or corroded hull surfaces. In industrial diving, they also guard against chemical residues. - Knife or Cutting Tool:

A safety essential for emergencies, such as a net, rope, or cable, is for entanglements. - Breathing Apparatus:

Either surface-supplied air systems or scuba tanks, equipped with regulators, backup gas, and monitoring gauges. - Umbilicals and Communication Systems:

Lifelines provide air, power, and two-way communication between the diver and the surface team. - Emergency Buoyancy Device:

Ensures safe ascent if the main system fails. - Head Protection:

Even light helmets or hoods shield divers from knocks, drops, or marine growth scraping.

Each of these contributes to compliance not only with IMCA safety guidelines but also with broader IMO regulations to globally standardize underwater safety protocols.

✅ 4 Things to Check for Safety at Sea pic.twitter.com/dAxhJQ2i6U

— Marine Super Cargo (@Marinsupercargo) September 14, 2025

Video Surveys and Inspections as Safety Allies

Before divers even enter the water, pre-cleaning hull video surveys can reduce unnecessary diving risks. High-resolution ROV inspections identify fouling hotspots, structural damage, or hazards like fishing gear entanglements. This minimizes diver exposure time—one of the most effective safety strategies.

By combining PPE requirements for divers with smart, tech-driven planning, owners achieve both safety and efficiency benefits. Also, read about underwater hull cleaning in Egypt.

Environmental Considerations

Maintaining safety gear is also tied to environmental responsibility. A damaged drysuit leaking lubricants, or broken masks releasing debris, can contribute to marine pollution. Regulatory bodies, including MARPOL and the International Association of Ports and Harbors (IAPH), urge tighter integration of diver safety with environmental sustainability.

For example:

- Gloves protect divers from toxic anti-fouling paints but also prevent material contamination.

- Closed-circuit helmets reduce exposure risks while minimizing gas wastage.

Common Mistakes in PPE Usage

Even when gear is available, many operators make avoidable mistakes during underwater jobs:

- Assigning improperly fitted suits or helmets, leading to leaks or restricted airflow.

- Failing to check redundancy—backup regulators, spare knives, or secondary light sources.

- Overlooking routine maintenance of gear seals, hoses, or regulators.

- Assuming divers are “overprepared” and skipping essentials like cutting tools.

In diving, complacency is the enemy. Safety requires discipline, constant reinforcement, and compliance with IMCA’s recommended codes of practice (IMCA Int).

Cost vs. Compliance: Why PPE Saves Money

At first glance, investing in divers’ PPE looks expensive. Helmets, drysuits, and communication gear make up significant costs. But consider the alternative: a single non-fatal diver injury can cost hundreds of thousands in medical, delay, and legal expenses. Non-compliance fines imposed by port authorities or classification bodies add to it.

Spending on PPE is not a cost—it’s an insurance policy. It also demonstrates your commitment to corporate responsibility, a rising demand from regulators and stakeholders alike.

Future of PPE for Divers

The industry is evolving, and technology is reshaping how we think about PPE requirements for divers. Innovations include:

- Smart helmets with integrated HUDs (Heads-Up Displays) for navigation.

- Exoskeleton suits reduce fatigue during labor-intensive hull cleanings.

- Biometric monitoring systems in suits to measure heart rate, oxygen uptake, and stress levels.

- Hybrid ROV-human operations, where divers are assisted by semi-autonomous machines.

These future-focused upgrades align with IMO and CleanShip.co sustainability efforts, reducing human risk while boosting performance outcomes.

Training and Compliance

Even the best equipment is useless without trained hands and disciplined users. Managers must ensure divers are thoroughly trained in:

- Donning/doffing PPE correctly.

- Responding to emergencies with gear redundancy.

- Performing daily safety checks.

- Understanding local port or flag-state rules connected to PPE.

Engaging with IMCA training programs ensures industry-recognized standards are consistently met.

Conclusion

When planning underwater maintenance or hull cleaning, PPE requirements for divers must take center stage, not as a checklist but as a structured life support system. Remember these key lessons:

- PPE safeguards both divers’ lives and company operations against risk and liability.

- Proper planning and compliance with IMCA, IMO, and MARPOL frameworks boost reputation and sustainability.

- Future innovations in diver PPE are redefining safety, efficiency, and environmental stewardship.

For reliable, sustainable underwater services emphasizing diver safety, visit CleanShip.co and discover solutions tailored for modern-day maritime operations.

FAQs:

Q1. What are the most critical PPE requirements for divers today?

Helmets, drysuits, gloves, cutting tools, and breathing support systems are essential. Together, they address core hazards like pressure, exposure, entanglement, and breathing difficulties.

Q2. Are PPE requirements for divers the same for scuba and commercial divers?

No. Commercial divers (e.g., hull maintenance divers) face more risks and require stricter PPE like surface-supplied helmets, umbilicals, and redundancy systems.

Q3. How often should divers’ PPE be inspected?

Before every dive. Detailed weekly and monthly inspections are recommended, with certified servicing annually or per manufacturer guidelines.

Q4. Who sets global PPE requirements for divers?

Bodies like IMCA, IMO, and classification societies issue globally recognized standards. Local port authorities may impose additional compliance rules.

Q5. Are there eco-friendly PPE innovations available?

Yes, sustainable materials for wetsuits and drysuits, along with closed-loop breathing tech, reduce both diver risk and marine environmental impacts.