Imagine setting out on a long road trip without checking your car’s engine, tires, or fuel level. You wouldn’t risk it, right? The same applies to ships before hull cleaning. A vessel’s hull is its most hardworking surface, exposed to constant friction, biofouling, and environmental stressors. Starting cleaning operations without knowing its actual condition can be disastrous—like fixing roof leaks during a storm without inspecting the structure first.

That’s why a Pre-Cleaning Hull Inspection combined with a thorough video survey has become a cornerstone of smart ship management. It gives owners, operators, and managers a crystal-clear picture of what lies beneath the waterline, allowing them to plan safe, efficient, and compliant hull cleaning operations.

This guide dives deep (pun intended) into why inspections matter, how they are performed, regulatory frameworks, common mistakes to avoid, and the innovations shaping the future of hull surveys.

Why Pre-Cleaning Hull Inspection Matters

Skipping a Pre-Cleaning Hull Inspection can cost you dearly—financially, operationally, and environmentally. Without proper assessment, cleaning teams may:

- Damage delicate antifouling coatings.

- Miss serious issues like corrosion or cracks.

- Waste time and money on inefficient cleaning methods.

- Risk non-compliance with IMO and MARPOL standards.

Conversely, inspections empower you to:

- Understand fouling type and extent.

- Chart the best cleaning method (brushes, ROVs, cavitation tools).

- Optimize fuel efficiency post-cleaning.

- Ensure ports and regulators won’t fine your vessel.

Think of it as a health check-up before surgery: the diagnosis dictates the treatment.

What Is a Pre-Cleaning Hull Inspection?

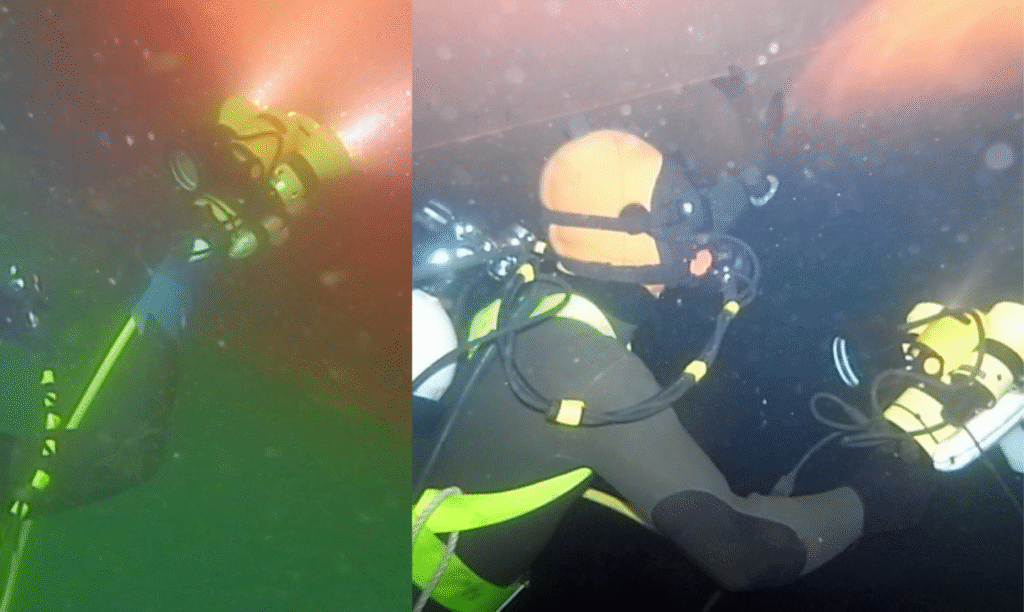

A Pre-Cleaning Hull Inspection involves divers or remotely operated vehicles (ROVs) conducting a visual or digital survey of a vessel’s submerged structure. Today, many companies use high-definition video capture, sonar imaging, and drones to map every square meter of the hull in detail.

Areas of focus include:

- Flat bottom and side shells.

- Sea chests, bilge keels, and bow thrusters.

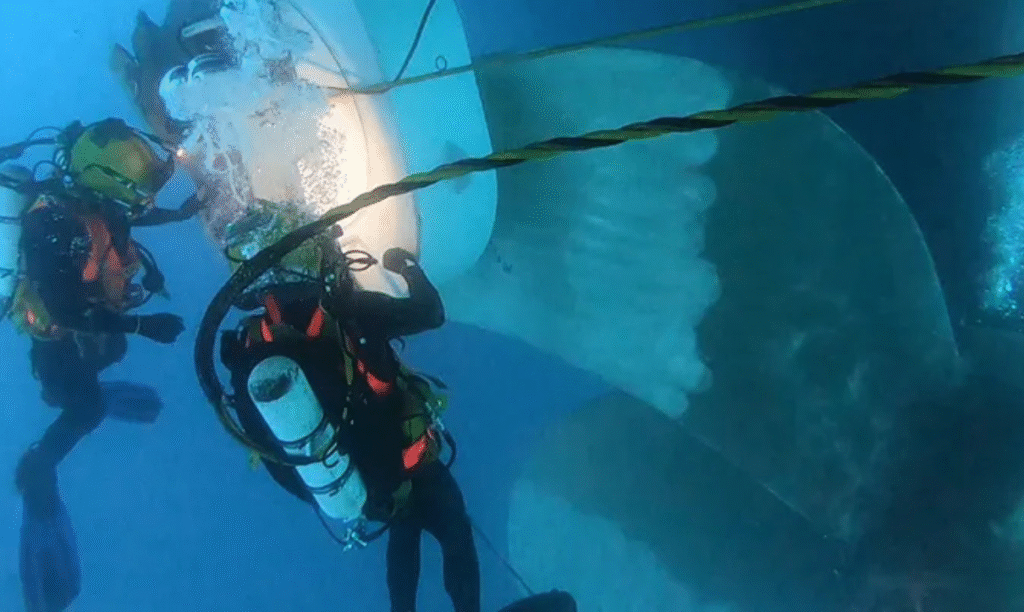

- Propellers, rudders, and stern gear.

- Coatings and cathodic protection systems.

The results provide a condition snapshot, guiding cleaning teams toward an effective and safe maintenance strategy. Learn more.

Benefits of Using Video Surveys

Traditional diver inspections rely on handwritten notes and memory. Video surveys have revolutionized hull inspection by offering:

- High-definition evidence – clear visuals of fouling and coating damage.

- Data tracking – comparable footage over multiple inspections to track deterioration.

- Transparency – ship managers, even remote ones, can review recordings.

- Accountability – contractors prove the necessity and avoid disputes.

According to IMCA, digital inspections not only improve safety by reducing diver exposure but also deliver better accuracy for maintenance planning.

Step-by-Step Process of a Pre-Cleaning Hull Inspection

A well-structured inspection is about precision. Here’s how most professional practices unfold:

- Pre-survey briefing: Coordination with crew and cleaning contractors.

- Environmental checks: Assess water clarity, currents, and port restrictions.

- Diver/ROV deployment: Equipped with cameras, lighting, and measurement tools.

- Footage recording: Each section of the hull was systematically documented.

- Problem identification: Fouling type, coating wear, corrosion, or cracks flagged.

- Report preparation: Annotated video files with recommendations delivered.

Environmental and Regulatory Compliance

Hull cleaning isn’t just about performance—it’s also a sensitive environmental matter. A Pre-Cleaning Hull Inspection ensures your cleaning plan aligns with key frameworks:

- IMO Biofouling Guidelines (2011): Require proactive biofouling management to prevent invasive species transfer.

- MARPOL Convention: Regulates pollution, including paint particles and biocide release during cleaning.

- IAPH Regulations: Varying port rules determine what’s allowed. Some ports ban in-water cleaning unless residues are captured.

By combining video survey documentation with cleaning records, you’re also building an auditable proof of compliance. Learn more at IMO.org and Marine Insight – MARPOL.

Key Mistakes to Avoid

Even with inspections, some common errors undermine efficiency:

- Skipping difficult-to-reach areas like sea chests or propeller hubs.

- Over-relying on divers without digital records limits future comparisons.

- Ignoring local water conditions, which may distort video clarity.

- Failing to act on findings quickly can lead to further fouling or damage.

✅ 4 Things to Check for Safety at Sea pic.twitter.com/dAxhJQ2i6U

— Marine Super Cargo (@Marinsupercargo) September 14, 2025

Cost vs. Savings Analysis

Yes, inspections add an upfront cost. But perspective is paramount. A Pre-Cleaning Hull Inspection can prevent coating damage worth thousands of dollars. It can also save 10–20% on fuel by enabling efficient cleaning timing. Compared to a single month’s fuel bill for a large cargo vessel, inspection costs are almost negligible.

Role of Contractors and Certification

Choosing the right inspection partner matters as much as cleaning contractors. Ensure they are:

- Certified by IMCA or equivalent.

- Experienced in handling large vessels.

- Equipped with high-definition video and ROVs.

- Transparent in reporting methods.

An uncertified team might overlook critical damage or fail to meet regulatory standards, creating compliance issues later. Read also about underwater hull cleaning in Ethiopia.

Future Trends in Hull Inspection

The shipping industry is seeing exciting innovations that will transform Pre-Cleaning Hull Inspection practices:

- Autonomous underwater robots capable of 24/7 data capture.

- AI-driven defect recognition analyzes video surveys automatically.

- Digital twin modeling, integrating hull inspection data into ship lifecycle monitoring.

- Cloud-based reporting, enabling instant sharing of inspection data across global teams.

These advancements streamline maintenance planning, align with decarbonization goals, and reduce costs long-term.

Real-World Analogy: The Doctor and the Patient

Think of your vessel as a patient. Would a surgeon operate without an MRI or X-ray? No. Similarly, starting hull cleaning without an inspection is like attempting surgery blindfolded. The video survey is your vessel’s diagnostic scan—revealing what needs treatment, what can wait, and what requires urgent attention.

Conclusion

A Pre-Cleaning Hull Inspection is not just a box-ticking exercise; it’s a safeguard against inefficiencies, fines, and costly repairs. Remember:

- Inspections identify fouling, coating condition, and hull damage in detail.

- Video surveys provide transparency, compliance documentation, and long-term tracking.

- The small upfront investment pays back through fuel savings, compliance benefits, and reduced downtime.

If you want reliable, professional, and eco-conscious hull surveys, consider partnering with industry leaders like CleanShip.co to future-proof your operations.

FAQs:

Q1. How often should I schedule a Pre-Cleaning Hull Inspection?

Every 6–12 months is recommended, depending on operating waters and fouling rates. Frequent inspections in tropical routes help reduce unexpected performance losses.

Q2. Can inspections be done while the vessel is at berth?

Yes, most inspections are performed at berth using divers or ROVs, provided port authorities permit in-water surveys. Always coordinate with local regulations first.

Q3. Are video surveys mandatory under IMO regulations?

Not mandatory, but highly recommended. They provide documentation for compliance checks and are considered a best practice under IMO biofouling guidelines.

Q4. What if the water is too murky for video inspection?

In such cases, divers may rely on touch surveys and high-powered lighting. Some companies also use sonar imaging for low-visibility waters.

Q5. Do inspections delay cleaning schedules?

No, inspections are typically quick (2–6 hours depending on vessel size) and help contractors plan cleaning efficiently, often reducing overall downtime.