Imagine standing on the deck of a massive cargo ship, watching waves ripple as the vessel pushes forward. Everything above the water seems strong and steady. But below, the hull tells another story. Over time, it becomes coated with layers of algae, barnacles, and slime. This process—known as biofouling—not only slows ships down but also demands frequent cleaning.

While hull cleaning restores efficiency, it introduces a problem often overlooked: chemical residues. These residues, left behind from paints, coatings, and cleaning methods, can leak into the marine environment, silently affecting ecosystems. Like invisible footprints, they linger long after the ship has sailed.

In this article, we’ll dive into what chemical residues are, why they matter, the risks they pose, regulatory frameworks, cost implications, emerging solutions, and future innovations that promise safer seas.

Why Chemical Residues Matter

Hull cleaning might sound like a simple maintenance task, but when you zoom in, it becomes clear how complex it is.

- Operational Efficiency: Fouling increases drag, forcing ships to burn more fuel. Cleaning restores smoothness.

- Hidden Risks: Along with fouling, antifouling coatings are often stripped away, releasing harmful substances.

- Environmental Damage: Chemical residues can harm coral reefs, fish, and plankton.

- Compliance: International frameworks like IMO and MARPOL demand pollution control.

So while hull cleaning reduces drag, it also introduces chemical residues that require careful handling.

Understanding Chemical Residues

Before exploring impacts, let’s define the term clearly.

- Chemical residues are trace amounts of substances—like copper, zinc, and biocides—left behind from antifouling paints and coatings.

- When hulls are cleaned, scrubbing and scraping can loosen these compounds, releasing them into the sea.

- Residues are invisible but persistent, accumulating in sediments and food chains.

Think of it like scrubbing a stained mug: the stain fades, but small particles mix into the wash water. On a ship, those particles don’t just disappear—they spread into ecosystems.

Also read about Underwater Ship Hull Cleaning in Ecuador.

Environmental Risks of Chemical Residues

Toxic Pollution

When chemical residues dissolve into water, they act like a slow poison. Metals like copper, often used in antifouling paints, can interfere with fish reproduction and damage coral growth.

Food Chain Contamination

Tiny plankton absorb chemical residues. Fish eat the plankton, larger species eat the fish, and the cycle continues—eventually affecting seafood consumed by humans.

✅ 4 Things to Check for Safety at Sea pic.twitter.com/dAxhJQ2i6U

— Marine Super Cargo (@Marinsupercargo) September 14, 2025

Bioaccumulation

Unlike natural waste, residues don’t break down easily. They accumulate in sediments, remaining for years and harming bottom-dwelling organisms. Learn more

Case Study Example

In Northern Europe, research showed high copper levels near busy shipping lanes, traced back to antifouling paint residues released during hull cleaning. This led to stricter regulations for in-water cleaning in many ports.

These examples highlight why chemical residues are a growing environmental concern.

Compliance and Regulations

Recognizing these risks, authorities have developed strict frameworks.

- IMO Guidelines: The IMO emphasizes safe cleaning methods to minimize chemical discharge.

- MARPOL Convention: As explained by Marine Insight, MARPOL regulates ship-based pollution, including paint and chemical waste.

- IMCA Standards: The IMCA sets best practices for marine contractors, encouraging containment and waste treatment.

- IAPH Initiatives: The IAPH works on harmonized policies across ports, preventing pollution gaps.

- Port Authority Rules: Many ports, especially in Europe and Asia, now restrict in-water cleaning unless advanced containment is used.

For ship operators, staying compliant isn’t optional. Non-compliance can lead to heavy fines, reputational damage, and even denial of port entry.

Cost Implications

Dealing with chemical residues isn’t just about compliance—it’s also a financial matter.

- Fuel Savings: Regular cleaning reduces drag, cutting fuel use by up to 20%. But improper cleaning that strips coatings increases costs long-term.

- Fines: Violations of MARPOL or local port rules can cost hundreds of thousands in penalties.

- Maintenance: Stripped coatings mean premature repainting and dry-docking—both expensive.

- Case Study: A bulk carrier in Asia faced $150,000 in fines for uncontrolled residue discharge. After adopting robotic cleaning with filtration, the ship saved $500,000 annually in fuel and avoided further penalties.

When managed well, reducing chemical residues isn’t a burden—it’s a cost-saving strategy.

Technical Approaches to Reduce Residues

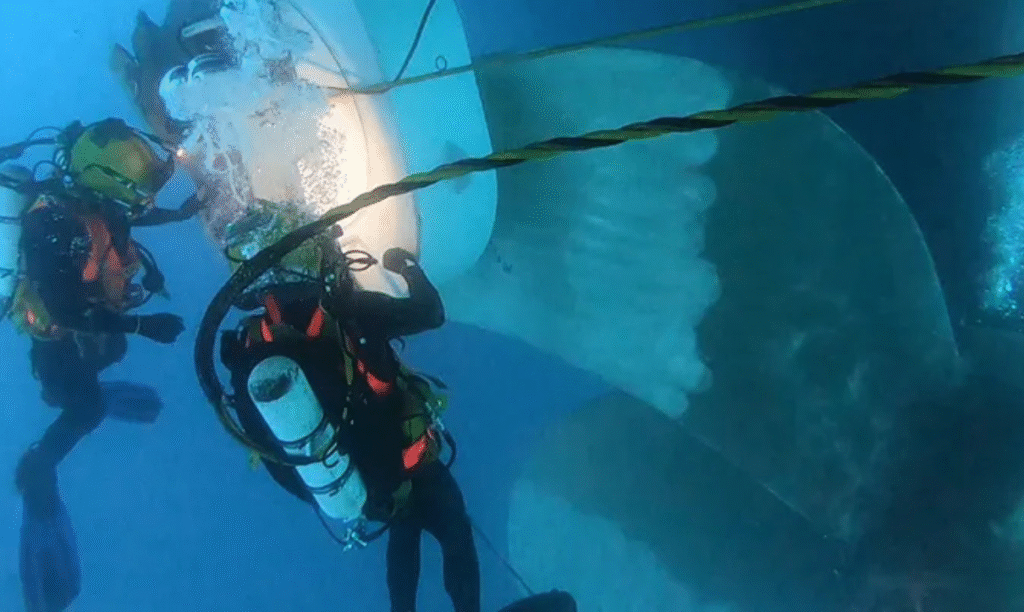

Robotic Cleaning

Autonomous underwater robots use cameras, brushes, and vacuums to clean hulls without aggressive scraping. Many capture debris, reducing the release of chemical residues.

Containment & Filtration

Advanced systems collect fouling, paint chips, and chemicals, filtering water before releasing it back into the sea.

Cavitation Jet Cleaning

This technique uses water jets with microscopic bubbles. It gently removes fouling without stripping coatings, preventing excess residue release.

Nanotechnology Coatings

Biocide-free coatings are being developed that naturally repel organisms. With fewer toxic chemicals, they minimize harmful residues from the start.

Role of Service Providers

Companies like CleanShip.co are pioneering eco-friendly solutions by combining robotics, filtration, and compliance-driven practices, ensuring efficiency without worsening chemical residues.

Future Innovations in Hull Cleaning

The future looks promising, with technology tackling the problem from multiple angles.

- AI-Based Monitoring: Sensors predict fouling buildup and optimize cleaning schedules, reducing unnecessary scrubbing that releases residues.

- Eco-Friendly Coatings: Next-generation nanotech coatings will reduce or eliminate biocides.

- Global Regulations: The IMO and IAPH are moving toward harmonized international standards.

- Green Certifications: Shipping companies will increasingly need certifications proving eco-friendly hull cleaning practices.

- Integrated Solutions: Future systems will combine robotics, AI, and eco-coatings to minimize drag and prevent chemical residues entirely.

Conclusion

Hull cleaning is essential for efficient shipping, but chemical residues pose hidden challenges. They pollute waters, contaminate food chains, and increase regulatory risks. The good news is that technology and regulations are pushing the industry toward smarter, cleaner solutions.

The three key takeaways are clear:

- Chemical residues are invisible but dangerous.

- Compliance saves both the environment and money.

- Innovative solutions, like those from CleanShip.co, ensure sustainable hull care.

By choosing eco-friendly methods, ship operators can protect oceans, cut costs, and future-proof their fleets.

FAQs:

Q1. What are the chemical residues in hull cleaning?

They are traces of copper, biocides, and other substances from antifouling paints that enter the sea during hull cleaning.

Q2. Why are chemical residues harmful?

They poison marine life, accumulate in sediments, and contaminate food chains, creating long-term environmental risks.

Q3. Which regulations address chemical residues?

The IMO, MARPOL Convention, IMCA standards, and local port rules regulate cleaning to minimize harmful discharges.

Q4. Can robotic cleaning reduce chemical residues?

Yes. Robots with containment systems clean precisely and capture debris, preventing residues from entering the ocean.

Q5. How can ship owners manage chemical residues effectively?

By using eco-friendly coatings, scheduling regular cleanings, following IMO/MARPOL rules, and working with providers like CleanShip.co.