Imagine a busy shipyard where every second counts. You hear the hum of air compressors and the grunt of hydraulic pumps—each driving specialized tools, helping crews tackle everything from hull cleaning to crane lifting.

The debate over Hydraulic vs pneumatic tools is as old as industrial engineering itself, and for good reason. Each system offers unique strengths, limitations, and applications that impact how you manage fleet maintenance, ship repair, and offshore operations.

From winches to bolting equipment, hull cleaning robots, and surface prep tools, understanding Hydraulic vs pneumatic tools is essential for maximizing productivity, safety, and compliance. Choosing the right system isn’t just a matter of preference—it affects costs, efficiency, and environmental responsibility.

For shipyards aiming to optimize workflow, knowing the differences between Hydraulic vs pneumatic tools ensures crews use the right equipment for each task, keeping operations smooth and safe.

Let’s break down everything you need to know about hydraulic vs pneumatic tools, why the comparison matters, and explore five game-changing benefits for ship owners, managers, and operators.

Understanding Hydraulic Tools

Hydraulic tools use pressurized fluids—typically oil—to transmit force. The science is simple but mighty: applying force to a liquid in a confined space allows tremendous pressure to be directed exactly where you need it. Picture a toothpaste tube: squeeze one end and the paste pops out the other. Hydraulics take this concept to the next level, delivering consistent, high power for marine and industrial tasks. When considering Hydraulic vs pneumatic tools, hydraulics excel at heavy-duty operations where precise, sustained force is critical.

Applications:

- Lifting, pushing, and winching heavy loads (cranes, anchor handling)

- Steering and propulsion systems (rudders and thrusters)

- Hull cleaning robots and underwater machinery

- Hydraulic torque wrenches, bolt cutters, and presses

Understanding Pneumatic Tools

Pneumatic tools rely on compressed air. When you blow up a balloon and let it go, the escaping air creates rapid motion—now imagine that directed into a tool for sanding, grinding, or blasting barnacles off a ship hull. Pneumatics have fewer moving parts, run cooler, and avoid the risk of flammable fluids. For shipyards deciding between Hydraulic vs pneumatic tools, pneumatics are often favored for lighter, faster tasks where speed and simplicity matter.

Applications:

- Paint sprayers, grinders, and sandblasters

- Impact wrenches, drills, and fasteners

- Shallow-water hull cleaning or surface prep

- Manufacturing, electronics, and pharmaceutical processing

Advantages:

- Lightweight, easy to handle

- Clean—no fluid leakage risk

- Quick response and cycling speed

- Simple maintenance

- Safer in hazardous environments (no oil spills or fire risk)

Hydraulic vs Pneumatic Tools: What Sets Them Apart?

Benefit 1: Strength & Consistency

When you need brute force—lifting anchors, cutting steel, or operating heavy cleaning gear—Hydraulic vs pneumatic tools show clear differences. Hydraulics offer unmatched torque and hold power that stays stable under constant load and strain. Pneumatics shine when agility and speed trump force, ideal for tasks like blasting, grinding, and surface prep, highlighting why understanding Hydraulic vs pneumatic tools is essential for shipyard efficiency.

Read more: Underwater Ship Hull Cleaning in Ecuador

Real-world Example:

Hydraulic winches, cranes, and hull cleaning robots handle tough jobs such as moving massive mooring lines, controlling ship thrusters, and managing underwater cleaning heads. Meanwhile, pneumatic wrenches and sprayers excel at lighter, repetitive tasks, emphasizing the practical applications of Hydraulic vs pneumatic tools in modern shipyards.

Benefit 2: Safety & Risk Reduction

Safety is your top concern. Hydraulic vs pneumatic tools each have unique safety considerations. Hydraulics offer sealed, engineered systems designed for extreme loads, but leaking oil—if not managed—can create pollution and fire risk. Pneumatic tools, running on air, eliminate fluid leakage but must be protected from pipe ruptures and flying debris, demonstrating another key aspect of Hydraulic vs pneumatic tools in shipyard operations.

At Marine Super Cargo, we provide trusted marine cleaning solutions across 1,100+ ports worldwide. From hold cleaning to underwater hull cleaning and tank cleaning, our services are designed to keep your fleet fully compliant, efficient, and cargo-ready. pic.twitter.com/N5VYZZjlQH

— Marine Super Cargo (@Marinsupercargo) September 11, 2025

Compliance Reference:

IMO, MARPOL Annex V, and IMCA all require strict spill and tool risk management; modern hydraulics are built with biofluids and leak sensors to meet these standards. Pneumatic systems require pressure regulation and regular maintenance to comply with IMCA inspection checklists.

Benefit 3: Cleanliness & Environmental Impact

Clean operations safeguard both your crew and the ocean. Hydraulic vs pneumatic tools each play a role in maintaining clean and eco-friendly workspaces. Pneumatic systems, which only leak air, excel in highly clean environments—electronics, food industry, and surface prep. Hydraulic systems must employ containment, biofluids, and proper housekeeping to avoid spills, highlighting one of the key considerations when comparing Hydraulic vs pneumatic tools.

Hull Cleaning Perspective:

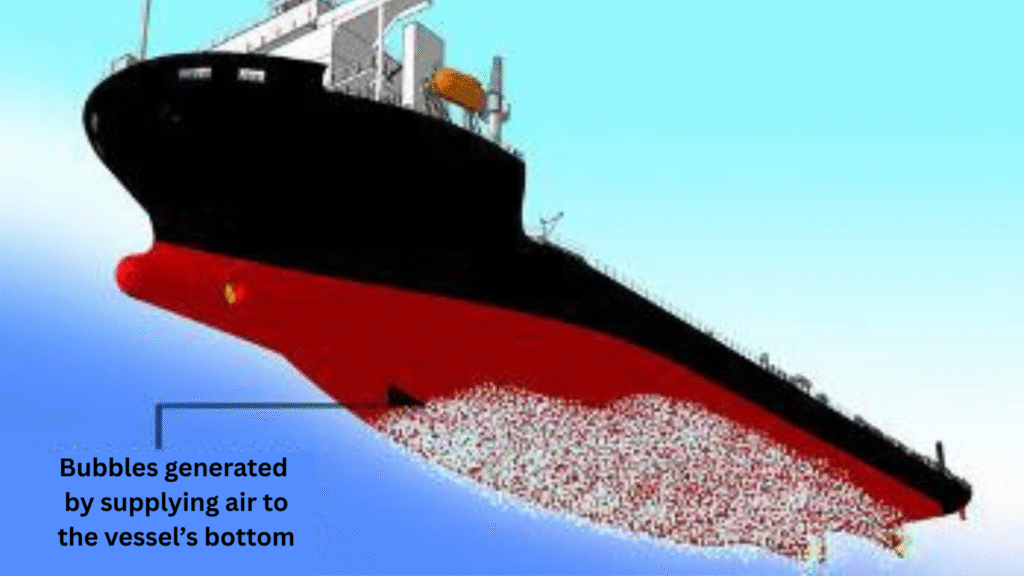

Eco-friendly hull cleaning technologies, like ROVs (Remotely Operated Vehicles) using hydraulic force with closed fluid systems, recover and dispose of debris without polluting the seabed. Pneumatic sandblasters, meanwhile, keep workshop environments dust-free with filtration units, showing practical applications of Hydraulic vs pneumatic tools in both underwater and surface operations. Overall, understanding the differences between Hydraulic vs pneumatic tools ensures environmental safety and operational efficiency.

Benefit 4: Cost Efficiency & Lifecycle

Tools must generate long-term value, not just short-term savings. Hydraulic vs pneumatic tools have unique economics:

- Hydraulics: Higher upfront cost but less downtime, longer tool life, and fewer replacements. Best for high-value, critical applications.

- Pneumatics: Lower purchase price, easy to maintain, but energy-hungry compressors and frequent repairs for high-use tasks.

Industry Insight:

Shipyards that carefully considered Hydraulic vs pneumatic tools and switched from all-pneumatic to combined hydraulic/pneumatic systems saw a 20% drop in tool replacement costs and saved 15% annually in labor downtime. Matching the right system to each task maximized ROI and highlighted the real-world advantages of Hydraulic vs pneumatic tools in modern shipyard operations.

Benefit 5: Versatility & Adaptability

Neither tool system is best for every job. Hydraulics excel for underwater, deep-sea, and heavy-duty applications—salvage, anchor handling, subsea robotics. Pneumatics rule in above-water settings—spraying, cleaning, painting—thanks to speed, light weight, and simple changeovers.

Fleet Manager Tip:

Smart operators deploy hydraulics for lifting and pushing, pneumatics for rapid cycling and high agility. Combining both systems ensures year-round flexibility and readiness.

Technical Jargon Explained

- PSI/BAR: Pressure measured in pounds per square inch (PSI) or bars. Hydraulics typically operate at much higher pressure (1,000–10,000 PSI) than pneumatics (72–145 PSI).

- Biofluids: Environmentally friendly hydraulic fluids designed to meet MARPOL compliance and reduce pollution in case of leaks.

- ROV: Remotely Operated Vehicle—a type of underwater cleaning robot driven by hydraulic or pneumatic systems.

- Winch Mechanism: Device for hauling or lifting using a drum and rope/cable, often powered by hydraulics.

Compliance & Regulatory Considerations

Maritime standards guide safe, sustainable tool usage while protecting workers and the environment.

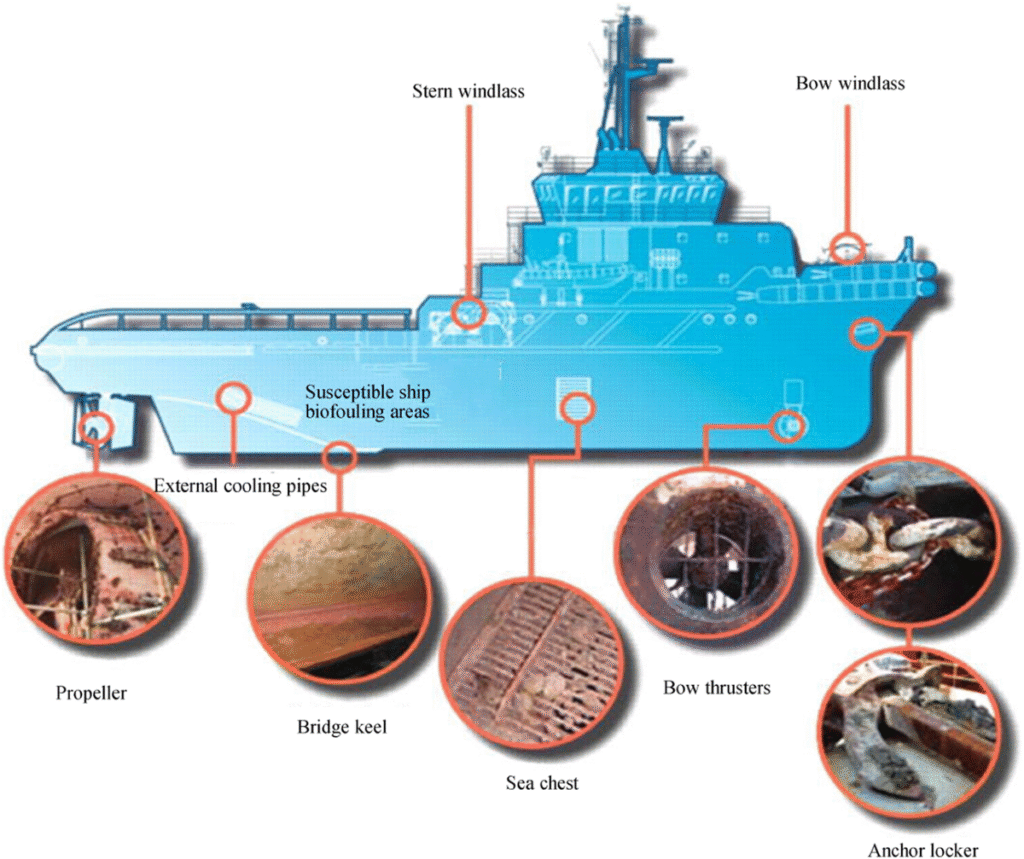

- IMO Biofouling Guidelines: Encourage responsible tool selection for hull cleaning, stress safe working practices.

- MARPOL Annex V: Strictly regulates fluid discharge from hydraulics; ships must demonstrate leak management and use of biofluids.

- IMCA e-CMID: Documents safety checks for underwater tool use (diver and ROV).

- IAPH Initiatives: Ports demand proof that maintenance operations minimize emissions and contamination.

By using hydraulic vs pneumatic tools intelligently and maintaining them per regulations, ship owners and managers avoid costly fines and protect their reputation.

Innovations & Future Trends

The industrial landscape is shifting fast. Key innovations you should know:

- Smart Hydraulic Monitoring: Sensors in hydraulic lines detect leaks instantly; predictive AI systems track fluid quality and maintenance schedules.

- Sustainable Hydraulic Fluids: Bio-based, non-toxic oils meet MARPOL/IMO requirements and help future-proof marine operations.

- Energy-Recycling Pneumatic Compressors: New compressor designs save 30% power; hybrid systems run cleaner and greener.

- Automated Hull Cleaning Robots: Eco-friendly ROVs combine hydraulic power for navigating heavy seas with pneumatic sprayers for surface cleanliness, supported by video feeds and debris capture capabilities.

Hull Cleaning: Why Tools Matter

As underwater hull cleaning goes robotic and eco-friendly, tool selection impacts not just mechanical results but compliance and biodiversity.

- Hydraulic hull cleaning robots (see SeaBadger, HullWiper) utilize carefully contained fluids and capture debris, aligning with IMO Biofouling guidelines for sustainable ship operations.

- Pneumatic hull sprayers and sandblasters, when paired with advanced filtration, minimize dust and air pollution in shipyard surface prep.

- Hybrid systems are the future: combining hydraulic force with pneumatic agility for optimized, all-weather, all-depth cleaning.

Conclusion

Hydraulic vs pneumatic tools form the foundation of marine engineering, hull cleaning, and shipyard operations. Your choice isn’t about which is “best”—it’s about matching power, cost, safety, and compliance for each task.

Key takeaways:

- Hydraulics deliver the unmatched strength and stability needed for heavy-duty, underwater, and lifting operations.

- Pneumatics shine where speed, light weight, and cleanliness are key, dominating surface prep and rapid cycling jobs.

- Future-ready tool choices mean aligning with IMO, MARPOL, IMCA, and IAPH regulations, using eco-fluids, leak sensors, and energy-saving compressors.

To modernize your fleet or shipyard, blend both systems according to task demands, sustainability goals, and regulatory needs. For advanced, compliant hull cleaning and marine solutions, connect with seasoned experts at CleanShip.co.

FAQ:

Q1. Which is better for underwater hull cleaning: hydraulic or pneumatic tools?

Hydraulic tools are preferred underwater—they offer higher force and stability. Pneumatics are less suited for deep-sea or high-pressure tasks but excel in surface applications.