Have you ever watched a diver slip beneath the surface of a harbor, scrapers and brushes in hand, ready to tackle the slimy underbelly of a ship? On the surface, Diver Hull Cleaning looks like a straightforward maintenance job—scrape off the growth, polish the surface, and the ship is ready to sail faster and cleaner.

But the truth is, this traditional cleaning method carries risks, hidden costs, and environmental consequences that the industry can no longer ignore.

In this article, we’ll explore the story of Diver Hull Cleaning, how brushes and scrapers became the go-to tools, and why their limitations matter more than ever. You’ll discover the benefits, the risks, where international compliance stands, and what the future of hull maintenance looks like in a greener shipping industry.

Why Hull Cleaning is More Than Just Maintenance

Think of a ship hull as the lungs of the vessel. When it’s clear, the vessel breathes easily, gliding through the water with minimal effort. When it’s clogged with layers of biofouling—barnacles, mussels, seaweed—it’s like trying to run a marathon while wearing a heavy backpack. Every extra organism adds drag, burns more fuel, and increases emissions.

Hull cleaning is therefore about more than appearance. It affects:

- Fuel Economy: Biofouling can increase fuel consumption by 10–40%.

- Speed & Efficiency: Even a thin film of slime slows vessel performance.

- Structural Life: Growth accelerates corrosion and damages coatings.

- Regulatory Compliance: IMO, MARPOL, and IAPH demand clean, sustainable operations.

- Invasive Species Prevention: Scraping organisms directly into new waters risks spreading species across continents.

These points highlight why the industry has depended on Diver Hull Cleaning for decades—but also why it must now rethink its approach.

What Is Diver Hull Cleaning?

Diver Hull Cleaning is one of the oldest methods in the maritime maintenance toolkit. It relies on professional divers entering the water with manual or powered tools to clear fouling organisms from a ship’s hull.

The process typically involves:

- Preparation: A dive team suits up with safety equipment in port or anchorage.

- Tools: Wire brushes, hydraulic scrapers, and sometimes suction equipment.

- Execution: Divers methodically scrape away fouling, often working in poor visibility, currents, or hazardous environments.

- Waste Disposal: In traditional setups, fouling is released directly into surrounding waters.

For many operators, this method appears simple, flexible, and budget-friendly—but the hidden complications are becoming harder to ignore.

The Hidden Risks of Diver Hull Cleaning

While Diver Hull Cleaning sounds economical, it comes with seven major drawbacks.

- Environmental Fallout

Scraped-off organisms often survive and settle into new ecosystems as invasive species, threatening biodiversity and local fisheries. IMO lists this as a leading concern in global biofouling management. - Risk to Divers

Working beneath a vessel’s moving parts and in low-visibility harbors exposes divers to injuries, entanglement, decompression sickness, and even fatal accidents. - Hull Coating Damage

Aggressive brushing strips away antifouling coatings. Once gone, biofouling regrows faster, requiring more frequent cleanings and higher costs. - Regulatory Challenges

MARPOL Annex V prohibits the improper disposal of fouling waste. Traditional brushing often fails to contain debris, creating compliance gaps. - Economic Fallout

At first, diver services are inexpensive. But when you factor in penalties, re-cleanings, coating repair, and fuel inefficiencies, the “cheap” choice becomes costly. - Operational Delays

Some ports now ban unsupervised or unfiltered diver cleaning. Non-compliance can force vessels into detention or unexpected dry-docking. - Reputational Damage

In a sustainability-focused shipping world, companies linked to pollution or invasive transfers risk reputational harm that affects customers, investors, and contracts.

From the Montreal Protocol on Ozone to the Paris Agreement on climate, and to the Minamata Convention on mercury, multilateral agreements unite countries to protect people and planet.

— UN Environment Programme (@UNEP) August 13, 2025

Now, #INC5 aims to add another milestone: a #PlasticsTreaty.

Explore more:… pic.twitter.com/aCS45SaH7X

Brushes & Scrapers: Tools of the Past

Brushes and scrapers became popular because they get the job done quickly and with little equipment. However, they lack finesse. Imagine trying to clean a luxury car with sandpaper—it removes the dirt but also damages the paint.

Traditional diver tools:

- Wire Brushes: Effective on slime and algae, but abrasive to coatings.

- Scrapers: Good for barnacles and mussels, but risk cutting into paint layers.

- Hydraulic Brushes: Faster, but still create uncontrolled plumes of biofouling waste.

These tools reflect a “quick fix” mentality: clean today, worry about tomorrow. But with rising environmental rules, “tomorrow” is here.

Compliance and Regulatory Spotlight

To ensure sustainability, maritime authorities have sharpened their focus on biofouling:

- IMO Biofouling Guidelines: Mandate management procedures to reduce invasive species transfer.

- MARPOL (Annex V): Bans harmful cleaning waste discharge into marine waters.

- IMCA: Provides diver safety frameworks, protecting workers from high-risk underwater operations.

- IAPH: Encourages ports worldwide to enforce stricter hull cleaning protocols.

In many regions, diver cleaning with brushes and scrapers—without containment systems—is restricted or outright prohibited.

⚓ Marine Super Cargo – Keeping Your Vessels Cargo-Ready 🌍

— Marine Super Cargo (@Marinsupercargo) September 10, 2025

At Marine Super Cargo, we provide trusted marine cleaning solutions across 1,100+ ports worldwide. pic.twitter.com/DnTQVk7lYX

Diver Hull Cleaning vs. Modern Eco-Approaches

How do brushes and scrapers compare to newer methods?

| Factor | Diver Hull Cleaning (Traditional) | Modern Eco-Friendly Systems |

|---|---|---|

| Upfront Cost | Low | Higher |

| Long-Term Cost | High (damage, fines, refouling) | Lower |

| Safety | Risky for divers | Safe, remote, automated |

| Environmental Impact | High (waste released) | Low (waste captured & treated) |

| Regulatory Compliance | Weak, increasingly restricted | Designed to meet IMO/MARPOL |

| Hull Protection | Coating damage possible | Coatings preserved |

| Fuel Savings | Short-term only | Long-term efficiency sustained |

Lessons from the Field

Take the case of New Zealand and Australia, where environmental agencies have restricted diver cleaning due to invasive species concerns. Ships that used brushes without waste control introduced species like Mediterranean fan worms, which now compete with native organisms and cost millions in eradication efforts.

This highlights the global message: uncontained Diver Hull Cleaning no longer fits the future of shipping.

Why Many Still Use Diver Hull Cleaning

Despite risks, this method persists because:

- It’s cheaper upfront than robotic solutions.

- Some operators don’t see the delayed costs until it’s too late.

- Not all ports enforce strict restrictions.

- Divers can be mobilized quickly in nearly any port.

However, as sustainability shifts from an optional policy to a requirement for staying in business, operators will need to transition to better methods.

Financial Perspective: The Real Cost

Let’s run a simple breakdown:

- Initial Diver Hull Cleaning cost: $10,000 per cleaning.

- Hull coating damage repair: $50,000–$100,000 per repaint cycle.

- Fines or delays for waste discharge: $20,000+ per violation.

- Fuel penalty for fouled hull: $200,000 per year for a mid-size vessel.

Now compare that to investing in modern hull-cleaning robots with waste capture—expensive upfront, but potentially saving millions over a ship’s operational lifetime.

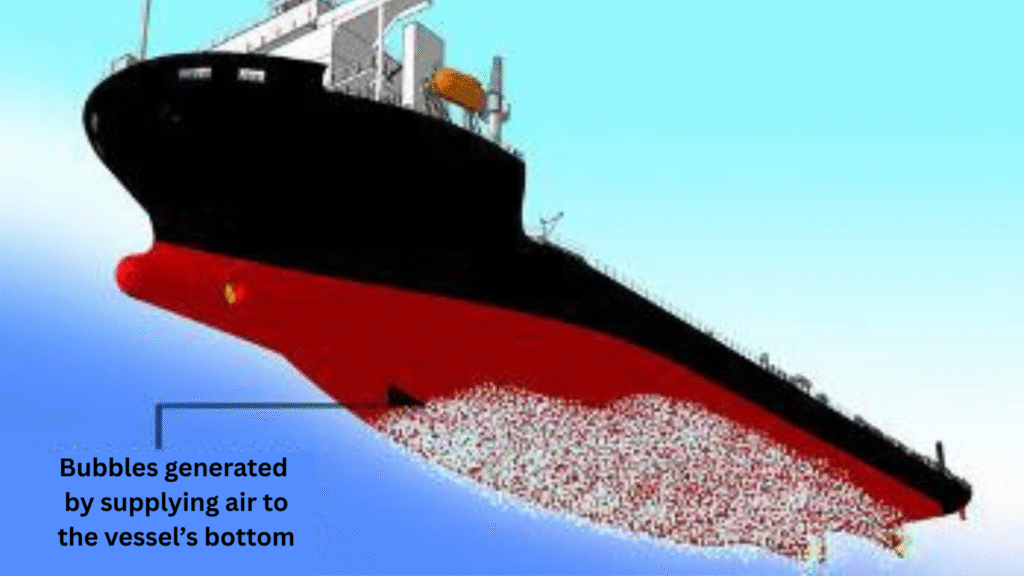

Future Innovations in Hull Cleaning

The traditional image of divers with brushes is giving way to smarter technologies:

- Robotic Hull Cleaning Drones: Automated crawlers that scrub while capturing fouling waste.

- Advanced Nanotech Coatings: Surfaces that organisms can’t stick to easily.

- AI Monitoring Systems: Predict fouling risks based on sea routes and vessel activity.

- Port-Based Containment Facilities: Authorized areas equipped to filter and clean debris responsibly.

Innovation makes Diver Hull Cleaning with brushes and scrapers less attractive each year.

Read more: Underwater hull cleaning in the UK.

Conclusion

Diver Hull Cleaning with brushes and scrapers has served the industry for decades, but its risks now outweigh its benefits. Remember three key points:

- Traditional diver tools often save pennies today but cost fortunes tomorrow in fuel, fines, and repairs.

- Environmental compliance is tightening, with IMO, MARPOL, IMCA, and IAPH leading stricter enforcement.

- Modern solutions exist—robotics, eco-friendly coatings, and data-driven systems—that ensure sustainability, safety, and efficiency.

If you want cost-effective, compliant, and environmentally responsible hull cleaning, it’s time to move beyond brushes and scrapers. For smarter, future-ready solutions, visit CleanShip.co.

FAQs:

Q1. Why is Diver Hull Cleaning still used?

It’s upfront, cheap, and widely available, but it masks long-term costs. Brushes and scrapers are slowly being phased out due to compliance issues.

Q2. What’s the biggest risk of Diver Hull Cleaning?

The uncontrolled spread of invasive species and the damage caused to antifouling coatings are the two most significant threats associated with this method.

Q3. Is Diver Hull Cleaning allowed everywhere?

No. Many ports now restrict or ban it unless waste containment and proper disposal systems are in place.

Q4. How often should ships be cleaned?

Most vessels require hull cleaning every 6–12 months, depending on voyage routes and coating effectiveness. Modern coatings may extend intervals further.

Q5. What’s the best alternative today?

Robotic, eco-friendly hull cleaning systems that capture waste and protect coatings while ensuring compliance with IMO and MARPOL standards.