South Africa isn’t just famous for its wildlife safaris or Table Mountain—it’s also a maritime giant. With strategic ports like Durban, Cape Town, and Richards Bay, the country is positioned on a key crossroad between the Atlantic and Indian Oceans. Every year, these ports manage thousands of vessels from tankers to cargo ships that connect continents.

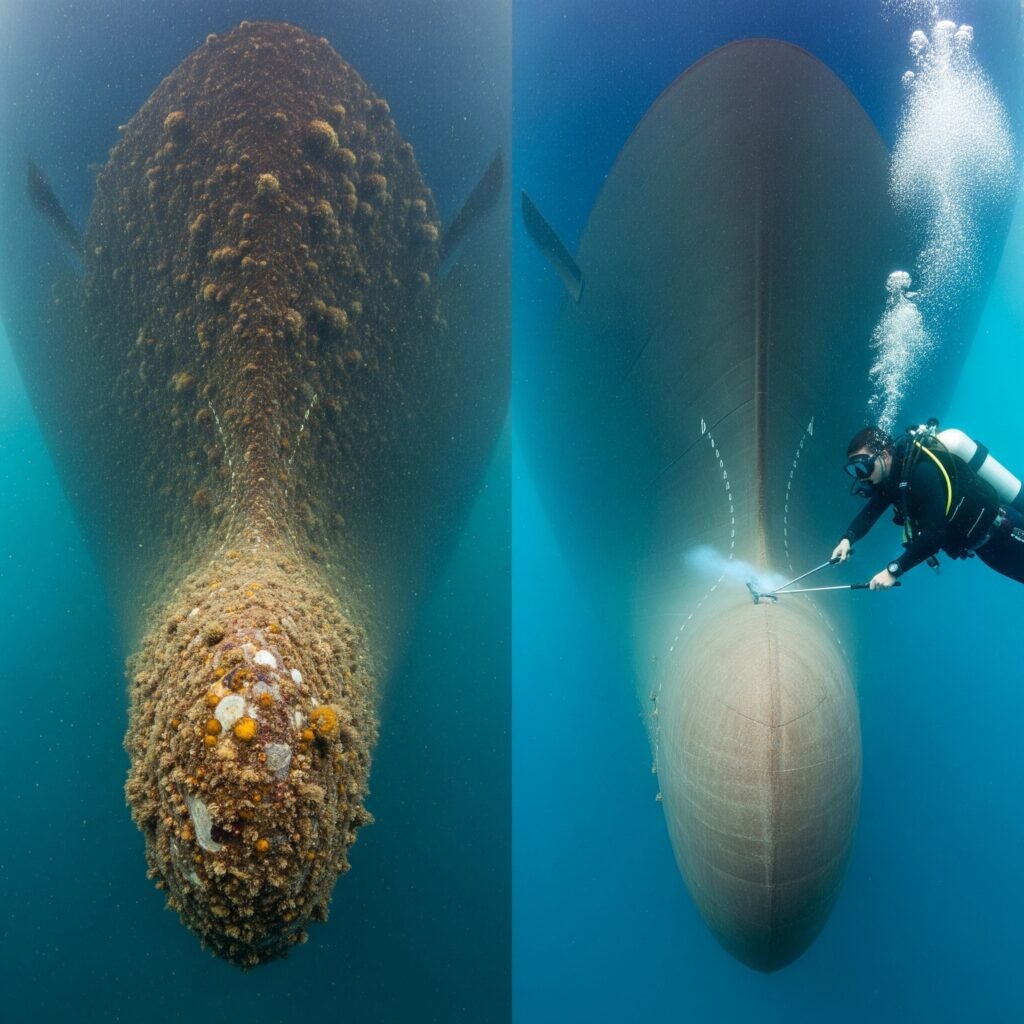

But one shared challenge hides below the waterline: biofouling. Barnacles, mussels, algae, and marine slime attach to ship hulls, dragging down performance and raising every voyage’s cost. That’s where underwater ship hull cleaning in South Africa comes in.

It might be carried out quietly beneath the waves, but its impact is loud—fuel saved, safety improved, and ecosystems protected. Let’s break down the underwater ship hull cleaning in South Africa.

What Exactly is Underwater Ship Hull Cleaning in South Africa?

Think of a ship’s hull as the smooth blade of a knife gliding through water. Now, cover that blade with sticky gum and barnacles—suddenly, slicing becomes a struggle.

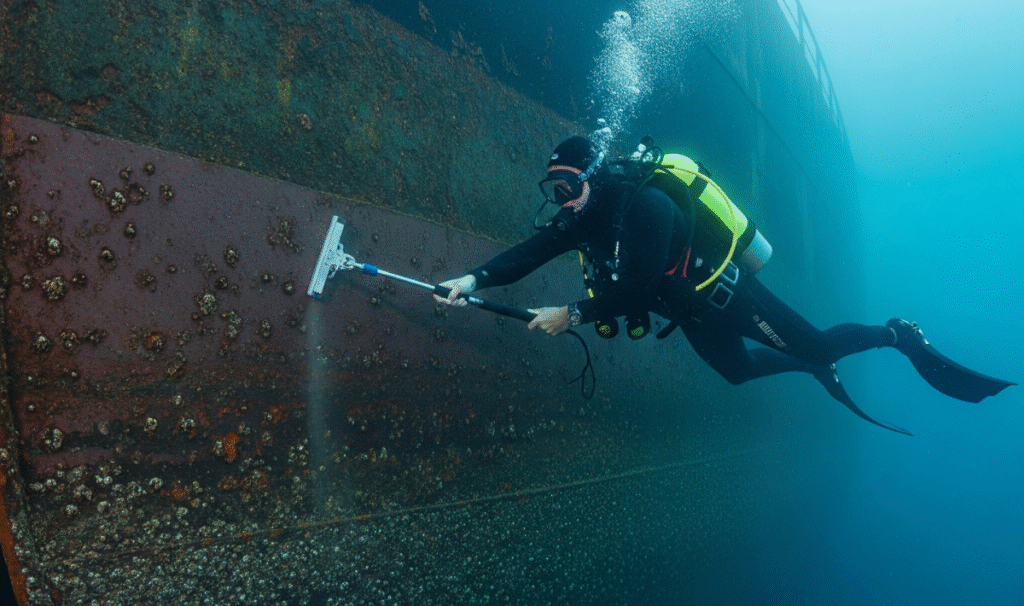

Underwater ship hull cleaning in South Africa is the process of sending trained divers or using robotic systems to scrub away biofouling under the vessel. The techniques may include brushes, suction filters, or cavitation jets. The result? A smoother hull, less resistance, and a ship that can perform closer to its original design.

The Drag Caused by Biofouling

Marine growth doesn’t stay small. Even a thin layer increases drag, forcing engines to work harder and burn more fuel. According to global studies, fouling can raise fuel consumption by 30–40%. For global fleets, that’s millions of dollars lost.

How Fuel Savings Create Long-Term Value

Regular underwater ship hull cleaning in South Africa removes this wasteful resistance. With drag reduced, ships burn less fuel and reach destinations faster. For operators trading through Durban or around the Cape of Good Hope, the financial savings per trip often outweigh cleaning costs many times over.

How Fouling Accelerates Corrosion

Marine organisms not only stick—they corrode. Fouling traps salty water against the hull, eroding protective coatings and exposing steel. Over time, this leads to weak points and costly structural issues.

Routine underwater ship hull cleaning in South Africa helps prevent premature corrosion. By keeping hulls clean, ships remain structurally reliable, avoiding sudden maintenance crises or expensive dry-dock repairs.

Staying Compliant with Inspections and International Standards

The IMO sets firm expectations for ship safety and efficiency. A fouled hull could fail inspection, leading to port delays and penalties. Underwater ship hull cleaning in South Africa keeps fleets inspection-ready and compliant with MARPOL pollution rules, ensuring smoother operations worldwide.

Reducing Carbon Footprints

Shipping contributes nearly 3% of global emissions (source: imo.org). A fouled hull increases fuel use and raises a ship’s carbon footprint unnecessarily.

By scheduling underwater ship hull cleaning in South Africa, operators not only cut costs—they also curb greenhouse gas emissions. Every clean hull means less fuel wasted and fewer emissions pumped into the planet’s atmosphere.

Preventing the Spread of Invasive Species

A mussel or barnacle attached in one part of the world can end up invading ecosystems in another. This is why MARPOL emphasizes hull fouling management.

Routine underwater ship hull cleaning in South Africa protects biodiversity along the country’s coastline and prevents foreign marine organisms from disrupting delicate ecosystems.

Why Underwater Hull Cleaning is Important in South Africa

A Strategic Location Between Oceans

South Africa sits on one of the busiest sea routes in the world: the connection between the Atlantic and Indian Oceans via the Cape of Good Hope. This makes it an ideal location for underwater ship hull cleaning in South Africa, as vessels can easily schedule services while stopping at its major ports.

Ports, Workforce, and Expanding Capabilities

Backed by guidance from imca-int.com and international standards outlined by iaphworldports.org, South Africa’s ports are building modern infrastructure and skilled diving teams. This ensures maritime services keep up with global best practices in safety and sustainability.

How Hull Cleaning is Done in South Africa

Step-by-Step Process

- Inspection: Divers or ROVs scan the hull to assess fouling severity.

- Cleaning Stage: Brushes, cavitation jets, or suction devices remove fouling.

- Polishing: Surfaces are smoothed to decrease drag.

- Debris Capture: Removed material is filtered to avoid polluting waters.

- Final Reporting: Shipowners receive documentation proving maintenance and compliance.

Modern Tools and Techniques Available

Underwater ship hull cleaning in South Africa often employs eco-friendly brushes, suction systems with debris filtration, and robotic tools that minimize diver risk while improving efficiency.

Challenges Faced in South African Waters

High Fouling Rates in Warm Currents

South Africa’s coastline spans warm and nutrient-rich waters that promote fast marine growth. Ships at anchor in Durban or Cape Town accumulate fouling much quickly compared to colder seas, making maintenance more urgent.

Balancing Cleaning Frequency with Costs

Too much cleaning risks stripping antifouling coatings; too little invites increased costs and emissions. The sweet spot? Scheduling underwater ship hull cleaning in South Africa roughly every 6–12 months, depending on ship operations and trade frequency.

Future of Hull Cleaning in South Africa

Greener Cleaning Technologies

Future hull maintenance will focus on sustainability. Expect biocide-free antifouling paints, eco-brushes, and waste-capture systems to become standard. South Africa’s ports are well placed to adopt and scale these eco-conscious innovations.

The Role of Robotics and AI

The future is digital. Imagine robots scrubbing hulls while AI tracks drag levels and predicts cleaning schedules. With ongoing maritime innovation, underwater ship hull cleaning in South Africa may soon be fully automated, faster, and safer.

Conclusion

What lies beneath the waterline may be invisible, but its impact is immense. Fouled hulls drain profits, shorten vessel lifespans, and threaten the environment.

The 3 key benefits of underwater ship hull cleaning in South Africa are:

- Fuel and cost savings from lower drag.

- Safer, longer-lasting ships strengthened against corrosion and inspection-ready.

- Cleaner seas, with reduced emissions and controlled invasive species.

For shipowners navigating Africa’s southern tip, hull cleaning isn’t just maintenance—it’s an investment in efficiency, compliance, and sustainability. Partnering with CleanShip.co ensures expert, eco-friendly hull cleaning solutions that protect vessels, save costs, and support greener oceans.

FAQ:

Q1. How often should ships undergo hull cleaning in South Africa?

Typically, every 6–12 months, though warm coastal waters might require more frequent cleaning.

Q2. Is underwater hull cleaning safe for coatings?

Yes, when done with modern eco-safe brushes and suction systems designed to preserve protective coatings.

Q3. Does hull cleaning really save fuel costs?

Absolutely. Cleaner hulls reduce drag, cutting fuel needs and generating significant savings.

Q4. Why is South Africa strategic for hull cleaning?

Because of its global crossroads between the Atlantic and Indian Oceans, underwater ship hull cleaning in South Africa is convenient during port calls.

Q5. Can hull cleaning protect marine life?

Yes. It prevents invasive species, reduces emissions, and maintains healthier ecosystems around South Africa’s coastline.