If you’ve ever been stuck in an airport because of unexpected delays, you know how frustrating and costly time lost can be. Now imagine that frustration multiplied across an entire shipping operation—that’s the reality when ships face PSC detention biofouling issues.

In this article, we dive into a case study where a vessel was detained by Port State Control because of excessive biofouling. You’ll see how this situation unfolded, what it cost the operator, and—most importantly—what you can do to avoid the same pitfalls.

What Is PSC and Why Biofouling Matters

Port State Control (PSC) inspections are carried out by maritime authorities to ensure vessels visiting their ports comply with international conventions such as MARPOL and IMO’s ballast water and antifouling guidelines.

When fouling organisms—like barnacles, mussels, or algae—cover a ship’s hull, authorities may identify it as a biosecurity threat. Why? Invasive organisms hitch rides on ships, spreading across marine ecosystems and harming local biodiversity. This is no small risk; it’s one of the top drivers of marine ecological damage globally.

So, when biofouling is discovered during PSC, the consequences can be serious: detentions, heavy fines, delays in cargo operations, and reputational damage for the ship operator.

The Case Study Scenario

The vessel in this case study, a 65,000 DWT bulk carrier, was detained in Oceania following a PSC inspection.

- Ship type: Bulk carrier

- Location of detention: New Zealand

- Duration of detention: 6 days

- Cause: Heavy biofouling discovered on the flat bottom and sea chest areas

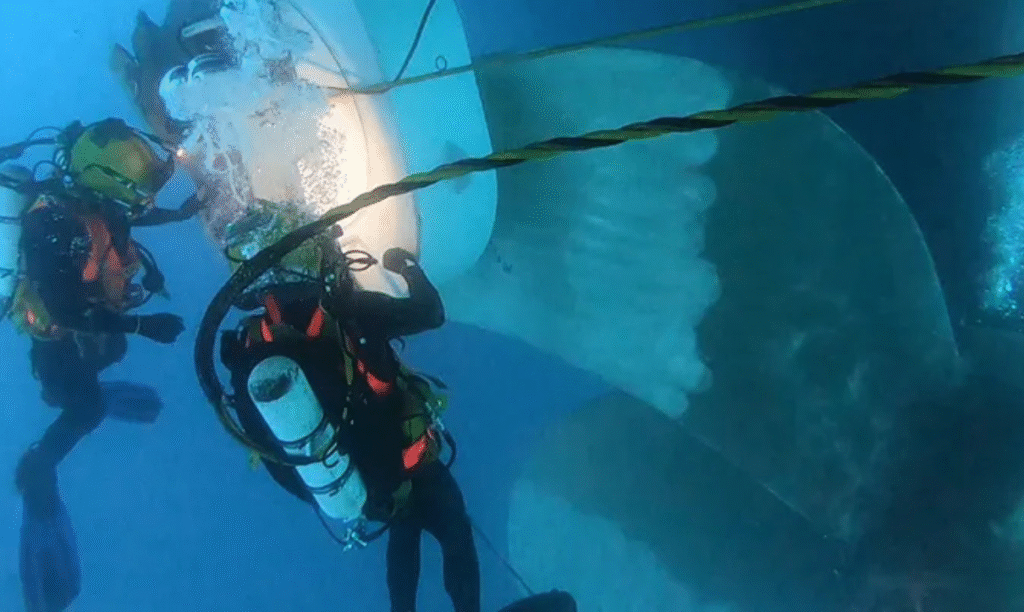

- Outcome: Vessel ordered to undergo full underwater cleaning before release

This wasn’t a paperwork issue. Divers deployed by port authorities documented thick barnacle growth and layers of slime that clearly violated local biofouling management regulations. What looked like a “routine check” turned into a costly nightmare.

Anatomy of PSC Detention Biofouling

The PSC detention biofouling problem stemmed from multiple operational mistakes:

- Skipped inspection: The operator delayed scheduled underwater hull inspections to reduce costs.

- Poor voyage planning: Long layover periods in warm, nutrient-rich waters encouraged aggressive fouling growth.

- Ineffective coatings: The anti-fouling paint applied during the last dry-docking already showed patchy performance.

When these factors are combined, the underwater hull becomes a breeding ground for organisms that faced strict rejection under local PSC rules.

The Real Costs of Detention

The financial harm of PSC detention biofouling can be staggering. In this case, the operator faced:

- Direct detention costs: 6 days off-hire during busy peak season.

- Underwater cleaning charges: Emergency cleaning arranged through certified contractors.

- Fuel inefficiency penalties: Biofouling added excess drag, consuming more bunkers before detention even occurred.

- Regulatory fines: Biosecurity-related penalties applied by port authorities.

Cumulatively, the detention exceeded $500,000 in direct and indirect costs—not counting reputational strain.

✅ 4 Things to Check for Safety at Sea pic.twitter.com/dAxhJQ2i6U

— Marine Super Cargo (@Marinsupercargo) September 14, 2025

Lessons Learned from This Case

The metaphor is simple: biofouling is like rust in the shipping industry—it spreads quietly until it becomes a major problem.

Key lessons from this detention:

- Procrastination costs more: Skipping inspections ended up doubling downstream losses.

- Geo-routes matter: Tropical and nutrient-rich waters demand tighter fouling controls.

- Coatings aren’t magic: Even the best antifouling paints degrade and need monitoring.

Compliance Frameworks You Must Know

International authorities are stepping up enforcement against fouling. According to IMO guidelines and environmental action plans:

- MARPOL Annex VI: Links hull efficiency to carbon emissions compliance.

- IMO Biofouling Guidelines (2011, updated 2023): Provide best practices for management.

- National standards: Countries like New Zealand and Australia implement stricter biosecurity laws to block invasive species.

Failing compliance here doesn’t just mean speed loss; it can mean detention and sanctions, as our case showed.

Risk Prevention: How to Avoid PSC Detention Biofouling

Thankfully, solutions exist, and they’re practical. To avoid PSC detentions:

- Routine inspections: Schedule inspections every 4–6 months in vulnerable waters.

- Hull grooming and cleaning: Use eco-friendly in-water cleaning tools approved by ports.

- Smart coatings: Invest in advanced anti-fouling systems with biocide or foul-release properties.

- Operational planning: Avoid long lay-ups in warm waters if possible.

- Data monitoring: Track ship speed and fuel data to detect fouling early.

Think of these as preventive “vaccines” for your vessel. The investment in good practices is significantly smaller than the catastrophic cost of detention.

Technology and Future Innovations

The shipping industry isn’t standing still. Innovations are making fouling management easier and safer:

- Robotic cleaning systems: Automated hull scrubbers are already reducing diver risks.

- Nanotechnology coatings: Cutting-edge solutions resist organism settlement longer.

- Biofouling forecasting models: AI predicts high-risk zones based on routes and environmental data.

- Global cleaning standards: IAPH and IMO are pushing for harmonized port-friendly cleaning rules.

These represent the future of risk mitigation—helping operators avoid PSC detention biofouling while staying ahead of both emissions and biosecurity compliance.

Key Insights Recap

Our case study shows that PSC detention biofouling can ruin schedules, inflate costs, and damage reputation. But with the right systems in place, it’s preventable.

Conclusion

In summary, this case study proves three powerful truths:

- Detention costs are preventable—inspection and cleaning save more than they cost.

- Compliance is tightening—PSC checks are stricter, especially for biosecurity.

- Technology offers solutions—from robotic cleaners to predictive models, prevention is smarter than cure.

Managing PSC detention biofouling is about more than saving money—it’s about staying compliant and protecting marine ecosystems. Stay proactive, invest in modern solutions, and safeguard your fleet. For comprehensive guidance and eco-friendly hull cleaning options, visit CleanShip.co.

FAQs:

Q1. Why does biofouling cause PSC detention?

Because fouling organisms pose serious biosecurity risks, ports restrict entry until vessels comply with standards.

Q2. Can all types of biofouling lead to detention?

Yes, heavy growth like barnacles is most visible, but even slime layers can breach strict rules in sensitive zones.

Q3. How costly is a typical PSC detention biofouling fine?

Costs vary widely, but fines plus delays often exceed hundreds of thousands of dollars.

Q4. Are ports uniform in their biofouling rules?

No, some regions like Australia and New Zealand impose stricter local rules in addition to IMO guidelines.

Q5. How can I best ensure long-term compliance?

Combine antifouling coatings, routine cleaning, data monitoring, and updated awareness of port requirements.